4 HANDLING

4-17

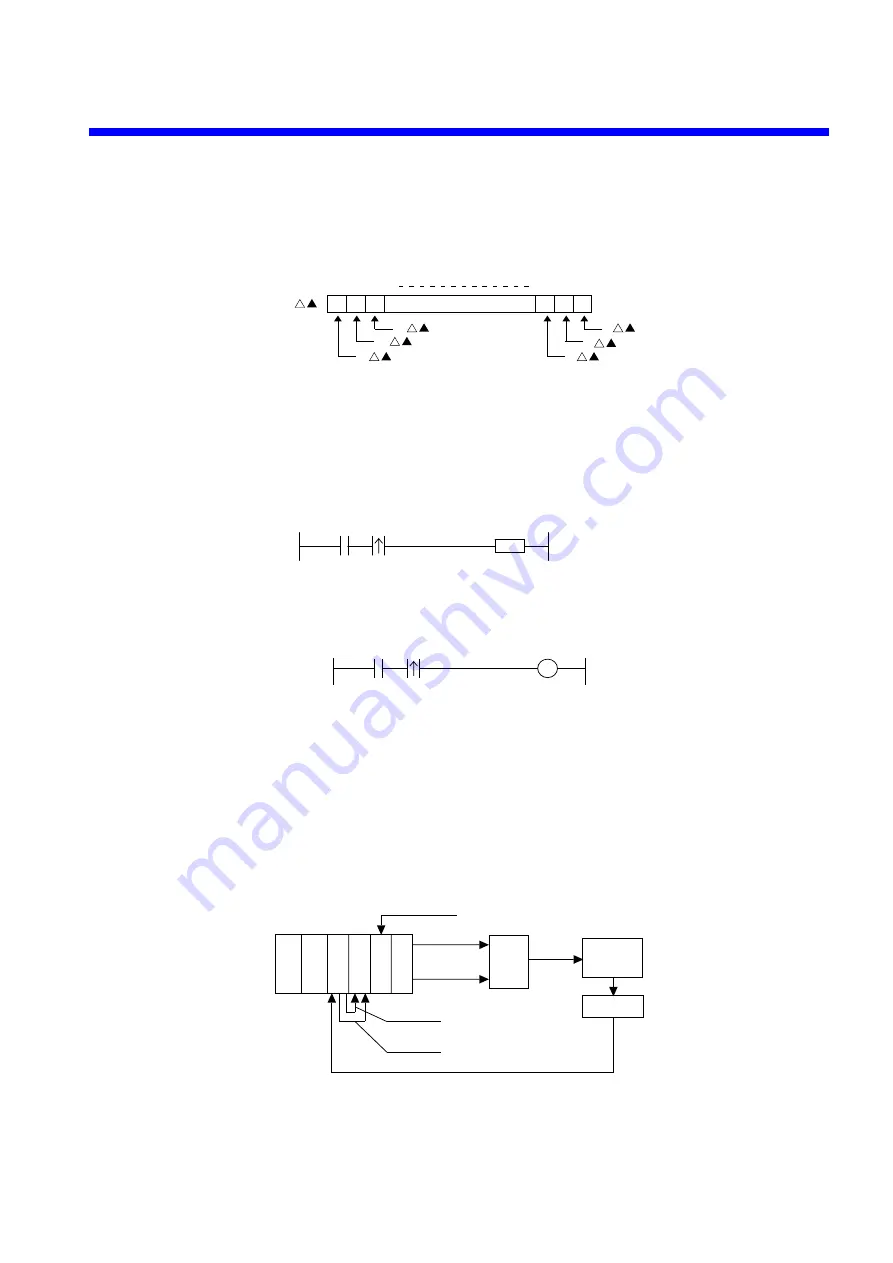

(f) Data area bit structure

Because the EW data area is structured as shown below, an operation code and a

status code in it can be used as a ladder contact and a coil, respectively.

EW

0

2

0

2

15

2

14

2

13

2

1

2

2

E

0

E

1

E

2

E

D

E

E

E

F

When a preset restart is implemented, for example, it can be set either as an

arithmetic function or as a coil as shown below.

z

Using an arithmetic function

DST

H4 = EW410

F

z

Using a coil

E41D

(g) Sample

program

y

Operation: Start a motor with an externally supplied start signal and then measure

the pulses generated from an encoder rotating with the movement of the

traveling table to let the motor move to a predefined position and stop.

y

Requirement: Let the program run in the flow shown Figurer 4-10.

y

Configuration: See below.

Motor

Traveling

table

Encoder

Y030

Y031

X020

X010

X011

Motor forwarding

Motor reversing

Two-phase pulse signal

R=C signal

R>C signal

Start signal

LQY200

LQX200

LQX200

LQC000

LQS000

LQV000

y

Mounting address registration: Assume that the LQC000 is allocated between

EW400 and EW430.

Summary of Contents for S10mini LQS070

Page 1: ......

Page 2: ......

Page 19: ...This Page Intentionally Left Blank ...

Page 30: ...1 BEFORE USE ...

Page 37: ...This Page Intentionally Left Blank ...

Page 38: ...2 KINDS AND SPECIFICATIONS OF I O MODULES ...

Page 57: ...This Page Intentionally Left Blank ...

Page 58: ...3 INDIVIDUAL SPECIFICATIONS ...

Page 143: ...This Page Intentionally Left Blank ...

Page 144: ...4 HANDLING ...

Page 179: ...This Page Intentionally Left Blank ...

Page 180: ...5 HANDLING I O DATA ON J NET ...

Page 186: ...6 HANDLING I O DATA ON D Station ...

Page 191: ...This Page Intentionally Left Blank ...

Page 192: ...7 MAINTENANCE ...