7 MAINTENANCE

7-2

7.1 Preventive

Maintenance

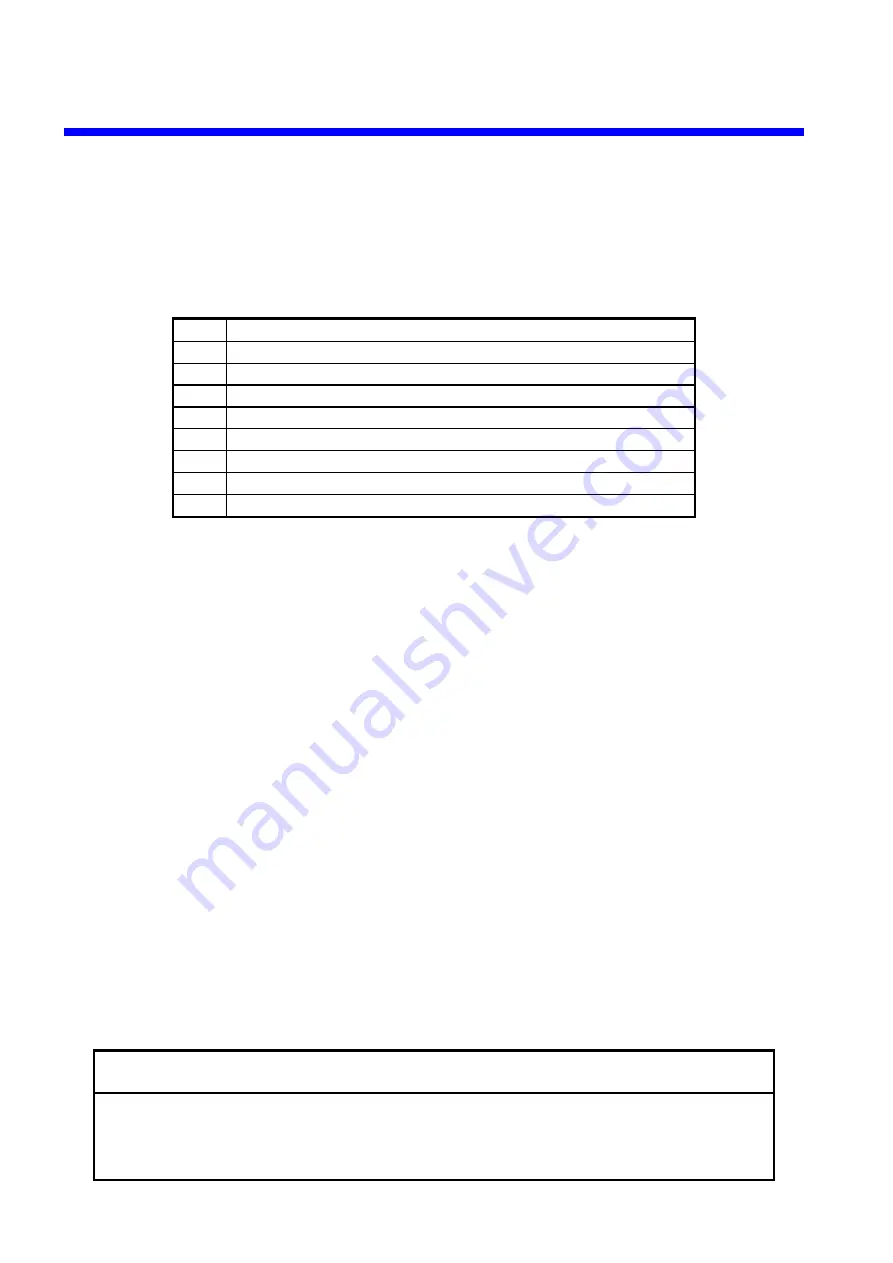

The inspections listed below are needed to keep the S10mini running in optimal condition.

Carry out these inspections daily or periodically (at least twice a year).

Table 7-1 Inspection Items

No. Item

①

Module

appearance

②

Indicator

status

③

Mounting screw and terminal block screw tightness

④

Cable and wire covering status

⑤

Dust

adhesion

⑥

Analog

precision

⑦

Supply input voltage

⑧

Supply voltage (power supply module and externally fed power supplies)

①

Module appearance

Check the module case for flaws, cracks and other defects. Defects in the module case

may be a sign of damaged internal circuitry, causing the system to malfunction.

②

Indicator status of illumination and indication

Check the indicators for unusual status.

③

Mounting screw and terminal block screw tightness

Check the screws, such as those used to mount the module and the terminal block screws,

for tightness.

If found loose, tighten them fully. Loose screws could cause the system to malfunction or

get burnt under heat.

④

Cable and wire covering status

Check the cable and wire coverings for defects and abnormal heat. Coverings out of

position or heated coverings could cause the system to malfunction, threatening electrical

shock hazards and getting the system burnt due to shorts.

⑤

Dust adhesion

Check to see if the module has not caught dust. Remove dust adhering to the module

using a vacuum cleaner. Adhering dust could cause a short in internal circuitry, causing

the system to get burnt.

CAUTION

The module is susceptible to electrostatic damages. Discharge electrostatic

charges from your body before setting switches, attaching or detaching cables, or

inserting or removing connectors.

Summary of Contents for S10mini LQS070

Page 1: ......

Page 2: ......

Page 19: ...This Page Intentionally Left Blank ...

Page 30: ...1 BEFORE USE ...

Page 37: ...This Page Intentionally Left Blank ...

Page 38: ...2 KINDS AND SPECIFICATIONS OF I O MODULES ...

Page 57: ...This Page Intentionally Left Blank ...

Page 58: ...3 INDIVIDUAL SPECIFICATIONS ...

Page 143: ...This Page Intentionally Left Blank ...

Page 144: ...4 HANDLING ...

Page 179: ...This Page Intentionally Left Blank ...

Page 180: ...5 HANDLING I O DATA ON J NET ...

Page 186: ...6 HANDLING I O DATA ON D Station ...

Page 191: ...This Page Intentionally Left Blank ...

Page 192: ...7 MAINTENANCE ...