5-8

Chapter 5

Installation and Configuration

5.7 System Configuration

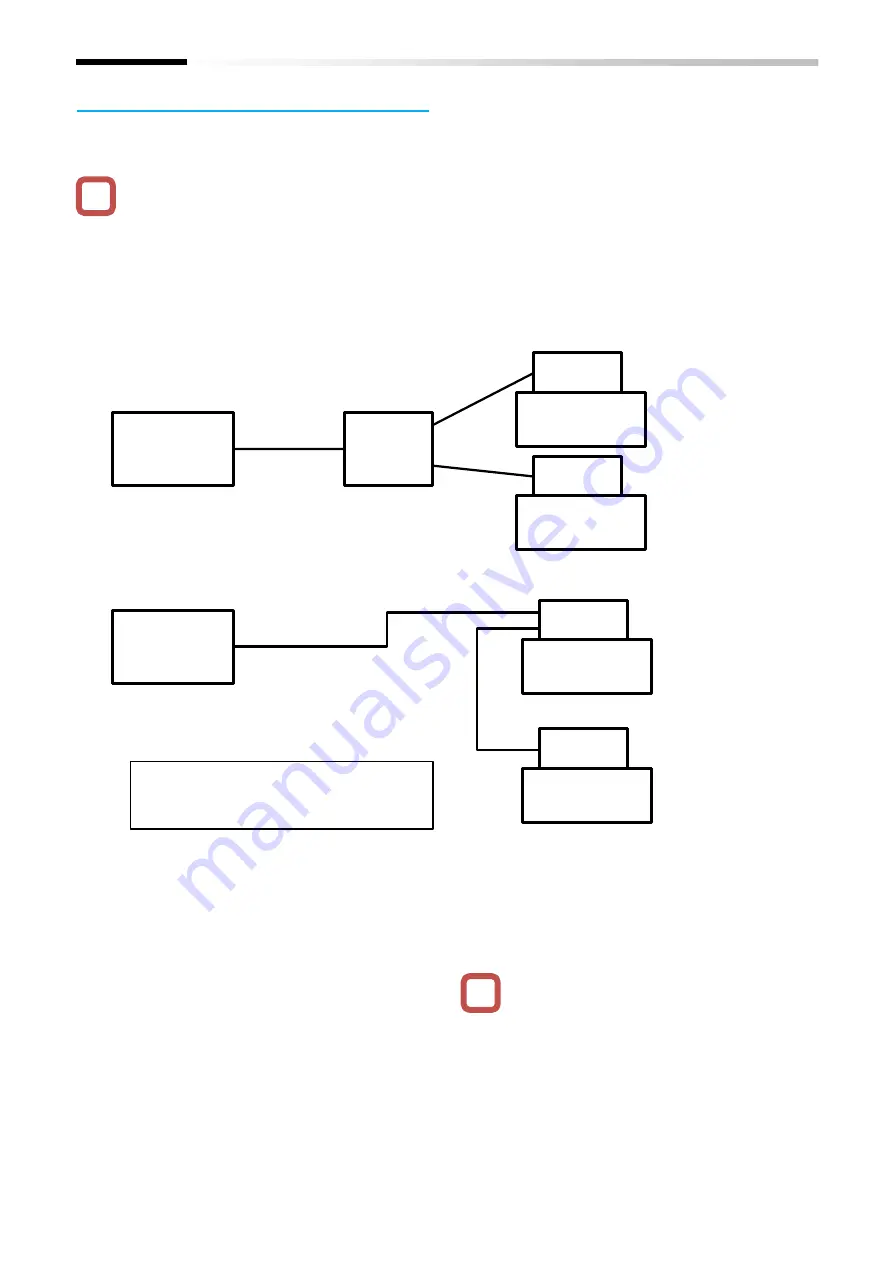

Examples of the Ethernet system configuration are

shown below.

・When configuring a system or confirming the

startup, read this guide and the instruction

manual about the client. The client means

higher-level device (master).

・Make sure that the communication line and the

power line are placed as far as possible from

each other. If the power line and the

communication line are placed close to each

other, the communication line will pick up noise

from the power line that can interfere with the

transmission.

・Make sure to set up the system, so that in an

event of a network failure, the inverter output

stops immediately. Instruct an example of

procedure as shown in "5.5 About the

connection".

・In case of configuring a system that the inverter

operates immediately at powered on, please

consider to take about 1 minute for the link

established.

[Function the network hub]

PORT1 and PORT2 are available as network hub

(shown in above example 2), if the inverter is

powered.

The only problem that the inverter can detect

related to the Ethernet connection is a

disconnection between this device and the

inverter. If a communication timeout occurs by

disconnection between this device and the client,

there is no function to accommodate in such a

trouble.

!

!

Client

(e.g. PLC)

Network

hub

P1-EN

SJ-P1

Ethernet

cable

P1-EN

SJ-P1

[Example 1]

[Example 2(using the function of network hub)]

Client

(e.g. PLC)

P1-EN

SJ-P1

P1-EN

SJ-P1

Ethernet cable

Server

Server and

network hub

Server

Ethernet cable can be connected with

either PORT1 or PORT2.

Server

Ethernet

cable

Ethernet

cable

Summary of Contents for SJ-P1 Series

Page 9: ...C 3 Table of Contents Memo ...

Page 17: ...1 8 Chapter 1 Safety Precautions Memo ...

Page 21: ...2 4 Chapter 2 Overview Memo ...

Page 25: ...3 4 Chapter 3 About the P1 EN Memo ...

Page 29: ...4 4 Chapter 4 Enclosed Items Memo ...

Page 45: ...6 8 Chapter 6 Inverter Settings Memo ...