--- 4 ---

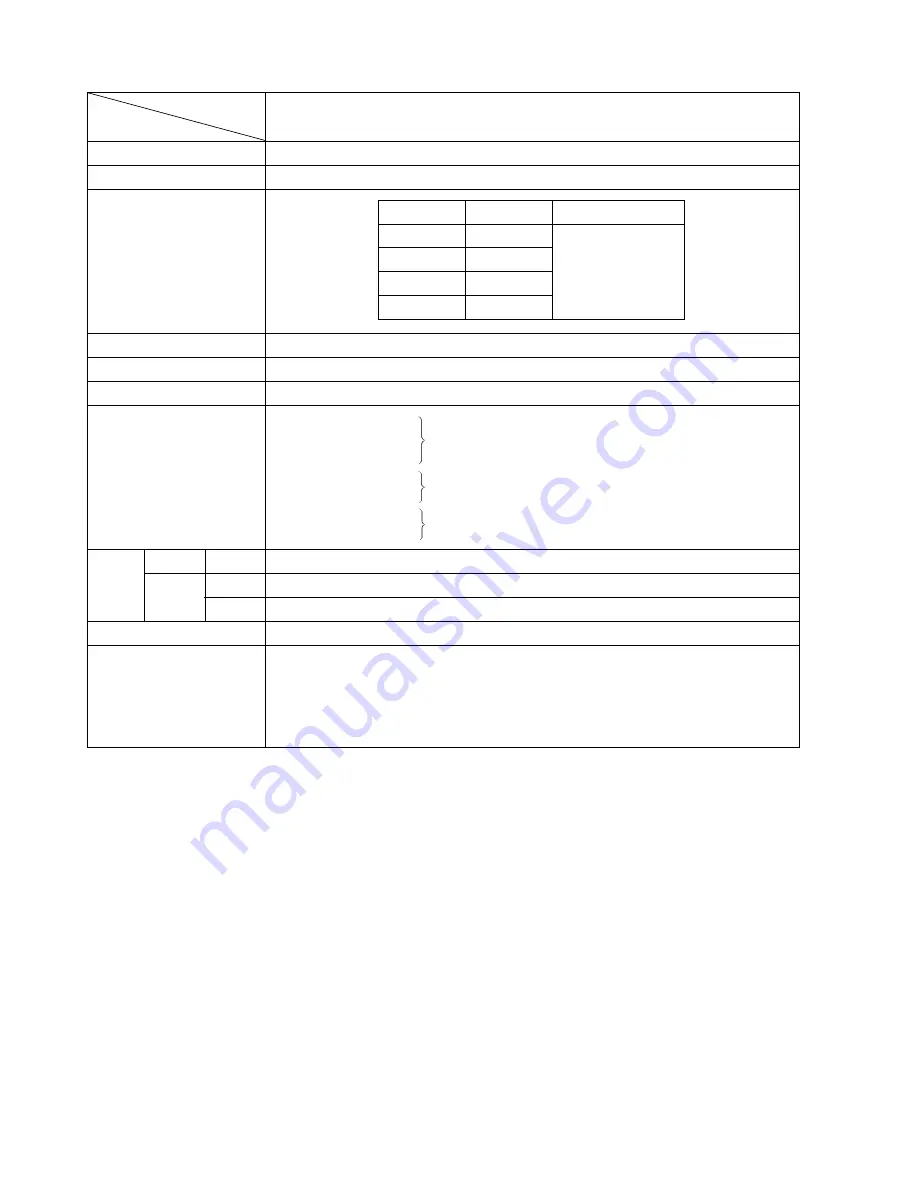

5. SPECIFICATIONS

Item

Model

SP 18SA

180 mm (7")

AC single phase 50 or 60 Hz

*

1

Weight excludes cord.

*

2

The standard accessories differ in some areas.

Capacity

Power source

Voltage, current and

power input

Rotation speed (no-load)

Type of motor

Type of switch

Enclosure

Catalog Net *

1

Weight

Actual

Net *

1

Gross

Packaging

Standard accessories *

2

2,000 /min

AC single-phase commutator motor

Trigger switch

Material: Housing

Handle cover

• • • • •

Glassfiber reinforced polyamide resin (green)

Tale cover

Gear cover

• • • • •

Aluminum alloy die casting

Inner cover

Painting: Gear cover

• • • • •

Metallic silver

Inner cover

2.9 kg (6.4 lbs)

3.1 kg (6.8 lbs)

3.8 kg (8.4 lbs)

Corrugated cardboard box

Rubber pad 180 mm (7")

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1

Wool bonnet 180 mm (7")

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1

Side handle

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1

Wrench

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1

Voltage (V)

Current (A)

Power input (W)

110

6.3

115

6.0

650

220

3.1

230

3.0