1. Carry out the electrical work according the local and

national electric codes and standards.

2. Connect the power supply for the main motor through

an earth leakage (ground) circuit breaker between the

main power and the Oilfree Scroll Air Compressor.

3. Wiring capacities are as follows.

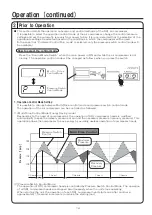

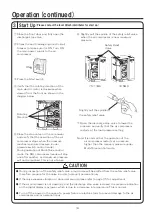

1. Internal air compressor wiring has been

completed prior to shipment from the

factory.

2. Remove the front panel, open the door

to the power supply panel and connect

the main power supply cable to the

terminal block.

Installation(continued)

8

● Verify that the power supply for the facility corresponds with the power supply of the air

compressor.

Failure to adhere to this precaution may lead to starting failure, electric motor failure and/or damage to the air

compressor.

● The SRL air compressor should be wired per the local and national electric codes. Improper wiring

may lead to excessive voltage drops.

● Do not use a generator.

CAUTION

5 Wiring the Air Compressor

Connecting the Main Power

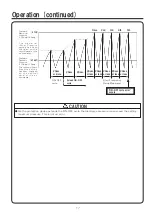

Model

Power

Wiring Capacity

Minimum Wire Thickness

(mm/AWG)

Minimum Ground Line Wire

Thickness

(mm/AWG)

Circuit Breaker

Capacity

(A)

Fuse

Capacity

(A)

SRL-7.5M6LL

SRL-7.5M6LH

208/230V

3 Phase

60 Hertz

3.9/AWG8

3.9/AWG8

75

75

SRL-11M6LL

SRL-11M6LH

4.9/AWG6

4.9/AWG6

100

100

SRL-16.5M6LL

SRL-16.5M6LH

6.8/AWG4

6.8/AWG4

100

100

SRL-7.5M6ML

SRL-7.5M6MH

460V

3 Phase

60 Hertz

3.9/AWG8

3.9/AWG8

40

40

SRL-11M6ML

SRL-11M6MH

4.9/AWG6

4.9/AWG6

50

50

SRL-16.5M6ML

SRL-16.5M6MH

6.8/AWG4

6.8/AWG4

50

50

Wiring the Air Compressor

Terminal

Block

Main Power

Supply Cable

T i g h t e n t h e n u t a f t e r

connecting the power

cable.

Note) 1. Use a UL489 listed circuit breaker or UL listed dual-element time delay branch circuit type fuses.

2. The Circuit Breaker and Fuse capacity depend on "UL standard".

Earth Leakage (Ground)

Circuit Breaker

Front panel