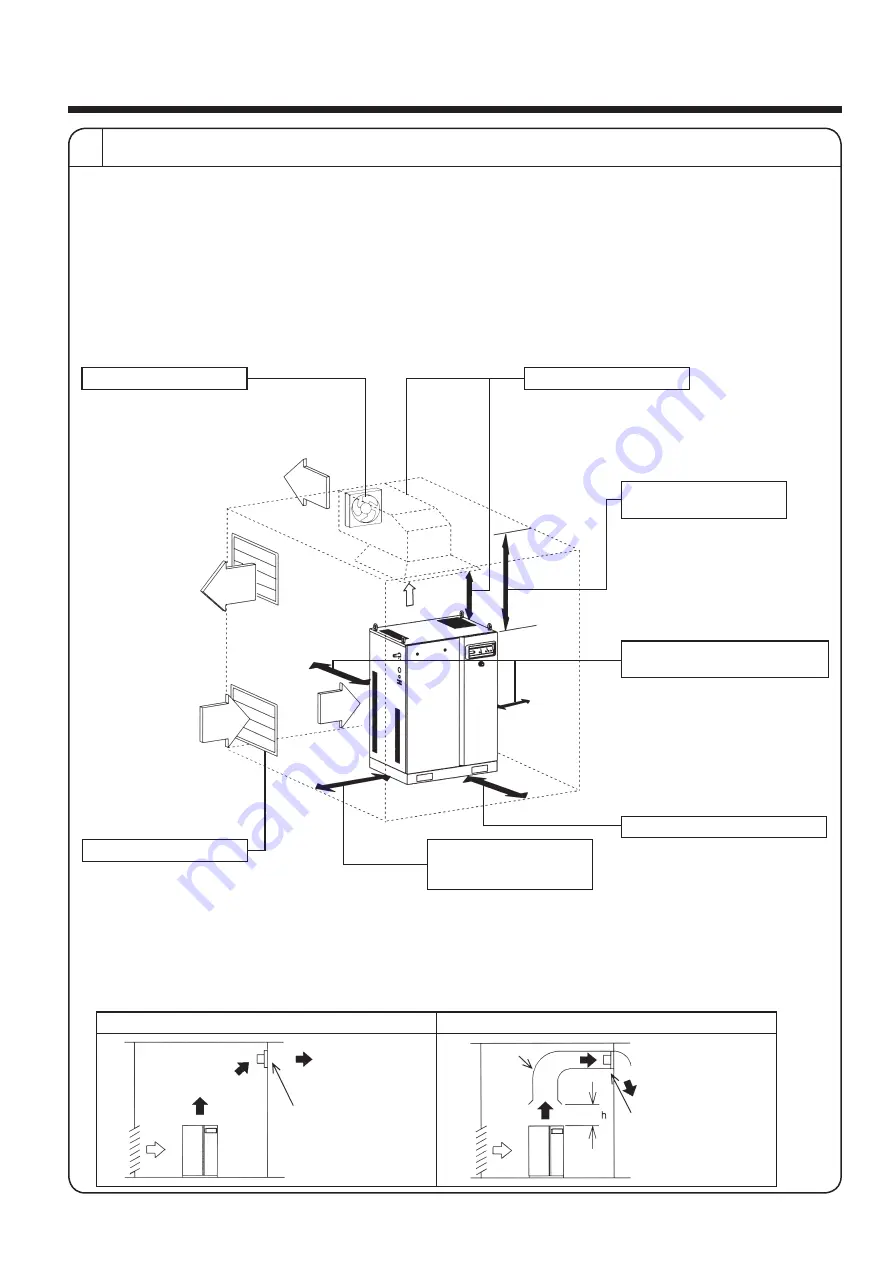

1. Install the air compressor inside a room with adequate space, ventilation and relatively low humidity.

2. Keep the operating room temperature in between 32° F and 104° F.

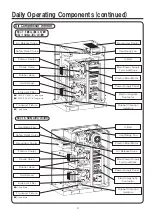

3. Install the air compressor with the recommended spacing shown in the figure below for ease of

maintenance and temperature control.

・The air compressor is designed to inhale air from the left side of the package and exhaust the air out

of the top of the package. It is recommended to provide suction and exhaust openings as shown in

the figure below to properly ventilate the room. If the suction and exhaust openings cannot be

provided, do not modify the air compressor without consulting the local Hitachi distributor.

4. The allotted space located to the right and to the rear of the air compressor must be maintained

to perform maintenance. Ensure that this space is maintained if the air compressor is going to be

permanently installed. (#)

A

B

Installation(continued)

5

3 Installing the Air Compressor

Ventilating fan

● If the temperature exceeds 104° F in the

room, install a ventilating fan to keep the

room temperature below 104° F.

● Select a ventilating fan with more than

enough capacity to handle the air flow of

the room.

Maintenance Space,

Intake Air, Discharge

Piping and Wiring

● Secure enough space for proper ventilation.

● Absence of intake space causes the suction resistance to

increase, resulting in temperature rise in the package, which may

cause a reduction in the life of air compressor components.

● Secure enough space for wiring and piping.

Ventilation and

Exhaust Space

● Secure enough space for proper

ventilation.

● Absence of intake space causes

the suction resistance to increase,

resulting in temperature rise in the

package, which may cause a

reduction in the life of air

compressor components.

Maintenance Space for

Right & Rear Sides

● If a space of more than 12 in.

and/or 20 in. cannot be secured,

utilize a piping connection that

can be easily removed for

maintenance purposes.

Front Maintenance Space

● Secure the proper amount of

space to open the front door of

the air compressor for inspection.

Exhaust duct

● Do not directly connect the duct with the

air compressor. The ducting hood should

maintain a distance (indicated as

“h”)

between the air compressor and the duct

that is larger than the diameter of the duct.

h

Exhaust

air

40 in. or more

Exhaust

Opening

Intake

Opening

Exhaust

air

I

ntake

air

I

ntake

air

12 in.

or more (#)

20 in.

or more (#)

Exhaust

air

40 in. or more

25 in. or more

Intake Opening

● The intake opening should be installed as

low as possible. The area of the opening

should be calculated as 1,550 sq in.(1m

2

)

per compressor1.

● Conditions of the ambient air, including

dust and toxic substances, should be

considered when selecting the location

for the intake air opening.

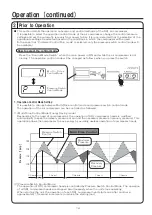

【Reference】

■ Guidance for construction of ventilating fan and exhaust duct

Exhaust Air

Exhaust Air

of air

compressor

Intake Air

■ Ventilating Fan

Refer to the volume of

necessary ventilation (1).

Intake Air

E x h a u s t

Duct

■ Ventilating Fan

Refer to the volume of

necessary ventilation (2).