2-1

●

Installing Precautions

●

The employed ink and makeup contain organic solvents. Furnish an

adequate space for the ink/makeup handling area and printer

installation site. A space of at least 400 m must be provided per print head.

Ensure that adequate ventilation is provided. Follow all regulation in your

country.

CAUTION

3

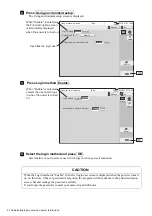

IJ printer

Maintenance area

300

mm

Top view

300

mm

300mm

750mm

2. INSTALLING PRECAUTIONS

●

Ensure that there is no flame- or arc-generating device around the printer.

The ink and makeup are both flammable and may cause fire.

Fire can be generated by matches, lighters, cigarettes, heaters, stoves, gas burners,

welders, grinders and static electricity. Arcs may be generated from open-type relays,

switches, and brush motors. Before handling the ink and makeup, remove static

electricity from your body, peripheral equipment, and so on. In the interest of safety,

position a dry-chemical fire extinguisher near the printer.

●

Since the ink and makeup contain organic solvents, install the printer at an

adequately ventilated location.

Never install the printer in an enclosed space.

Connect exhaust equipment to the printer in order to prevent it from filling with

organic solvent vapor.

WARNING

2

1

(1) Provide a clearance around the IJ printer for daily operation,

handling, and maintenance access (see the figure at right).

(2) The print head needs to be cleaned with the makeup while the

printer is operated and stopped (daily maintenance). Adopt a fixed

structure in consideration of print head cover and print head

removal.

(3) Installation must be completed so that no vibration will be applied to

the IJ printer main body, print head, or print head cable.

If they are vibrated, print quality deterioration and print irregularity

may be incurred (the maximum permissible vibration value is

1.96m/s ).

(4) The IJ printer main body must be installed with a levelness error of

not over ±1°.

(5) The IJ printer main body must be electrically insulated from the

other equipment (conveyors, packing machines,etc.), photoelectric

switches, and the rotary encoder.

(6) The standard distance between the printing head and the object to be

printed on is as indicated in the right-hand table.

The smaller the clearance between the print head and print target,

the smaller the character height and the better printing.

(7) The IJ printer proper requires maintenance as the occasion may

demand including replenishment of ink and makeup and

replacement of filter.

(8) If ambient humidity is 85 to 90%RH, you must purge inside of print

head by air. It is necessary for dry-clean air, regulator for pressure

of air and air filter. (Quantities of the air are 1L / minutes.)

* Leave a maintenance area of

at least 20 cm for the upside

of printer.

Distance between the printing head

and the object to be printed on

Nozzle diameter

Distance

65

μ

m

10 to 30mm

2