4

! " -

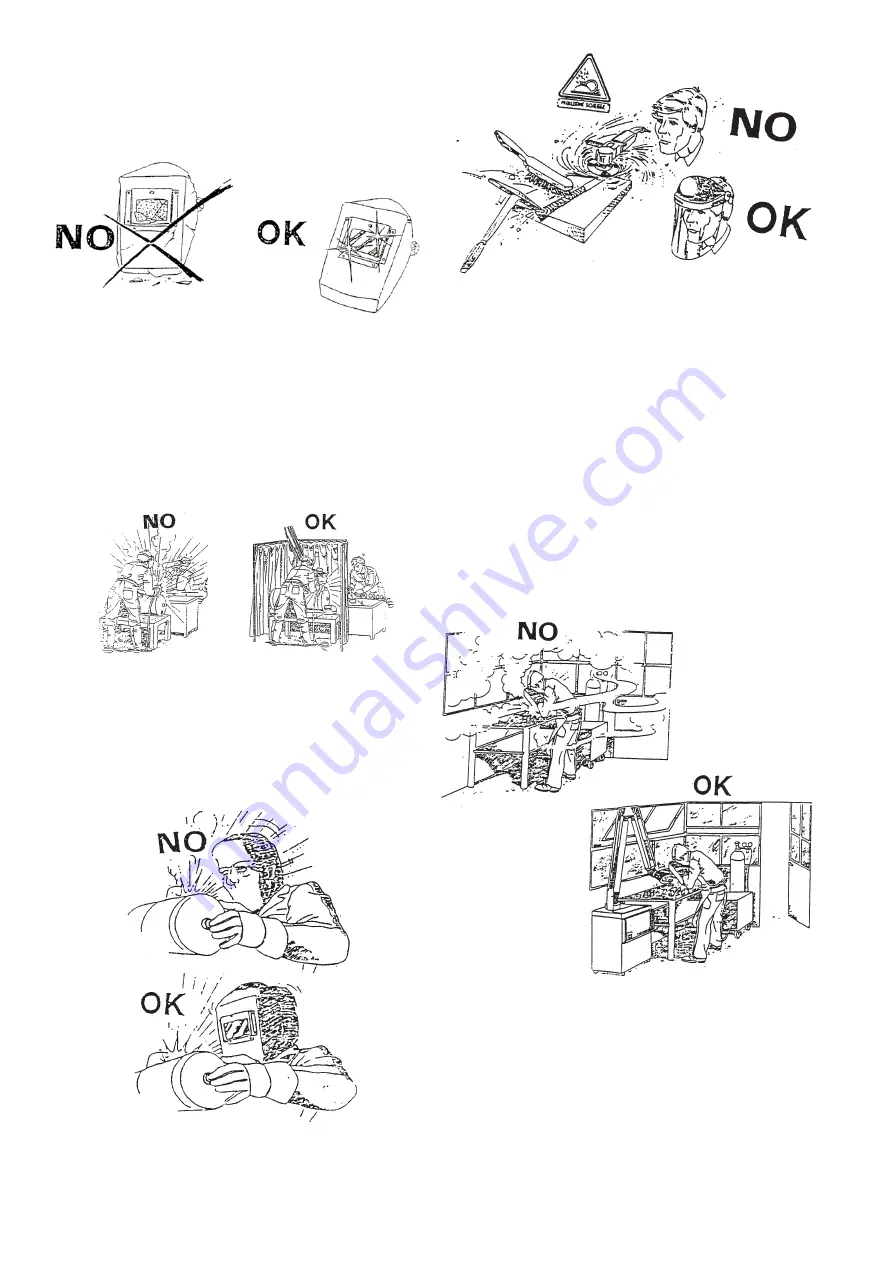

placed when incandescent spatters and de-

. !/

with coated plates that emit toxic fumes when

<

- Welding should be done in a closed area

that does not open onto other working areas,

in order to protect all workers against radia-

'

provided, the welding area must be delimi-

ted by protective screens painted in opaque

black large enough to restrain the visibility of

1# J3

- Remove all chlorinated solvents from the

! ! X -

nated solvents decompose when exposed to

- Never, under any circumstances, look at

an electric arc without suitable eye protection

1# [3

- Always wear protective goggles with tran-

sparent lenses to prevent splinters or other

1#

\3

- Adequate local exhaust ventilation must

'

through a mobile hood or through a built-

in system on the workbench that provides

exhaust ventilation from the sides, the front

and below, but not from above the bench so

exhaust ventilation must be provided toge-

ther with adequate general ventilation and

air circulation, particularly when work is done

1#]3 0

stain or soreness to the eyes, the nose or the

throat may be cause by inadequate ventila-

tion; work must be stopped immediately and

all necessary steps must be taken to provide

- Welding process must be performed on

metal coatings thoroughly cleaned from la-

yers of rust or paint, to avoid production of

" !

!

- Do not weld metal or painted metal con-

taining zinc, lead, cadmium or beryllium un-

less the operator, or anyone else subjected to

the fumes, is wearing respiratory equipment

<

#@

#J

#[

#\

#]

Summary of Contents for W200

Page 13: ...12 1 3 ª µ µ µ 1 3 J ª ...

Page 14: ...13 1 3 1 3 ª 1 3 º 1 J3 1 3 J ...

Page 15: ...14 1 3 1 3 1 3 ...

Page 16: ...15 1 3 1 3 À ª À J ...

Page 18: ...17 ª µ 1 3 ...

Page 19: ...18 1 3 J ª 1 3 Á Á ª 1 3 º Á Â Á 9µ µ µ µ J Â Á Â Â Á Â Â Á Â J Â Á Â Â Á Â 8 7 1 2 5 6 3 4 ...

Page 20: ...19 Á 1 3 1 3 Ã µ µ º ...

Page 21: ...20 J 1 3 À J 3 J 3 Å Æ J 0 Å 2 X 4 ...

Page 32: ...31 13 0 PARTS DRAWINGS EXPLOSIONZEICHNUNG W130 ...

Page 34: ...33 14 0 PARTS DRAWINGS EXPLOSIONZEICHNUNG W160 ...

Page 36: ...35 15 0 PARTS DRAWINGS EXPLOSIONZEICHNUNG W200 ...

Page 38: ...37 16 0 WIRING DIAGRAM SCHALTPLAN W130 PCB1 PCB2 PCB3 FAN 220 230V 50 60HZ TA HALL PROBE ...

Page 39: ...38 PCB1 PCB2 PCB3 FAN 220 230V 50 60HZ TA HALL PROBE 17 0 WIRING DIAGRAM SCHALTPLAN W160 ...

Page 40: ...39 18 0 WIRING DIAGRAM SCHALTPLAN W200 ...

Page 41: ...40 HITACHI HITACHI Á HITACHI W130 HITACHI W160 Ú µ Á µ Å µ Å Å J Å 1 3 1 3 1 3 1 3 Ë ...

Page 42: ...41 9 0X9 µ µ µ µ µ µ 1 3 µ µ µ Å ...

Page 43: ...42 ÀÀÀÀÀÀÀ ÛÛÛÛÛÛÛÛÛÛ ÛÛÛÛÛÛÛÛÛ ÛÛÛÛÛÛÛÛ ÛÛÛÛÛÛÛÛÛÛÛÛ ...

Page 45: ...77611267 ...