English

11

(3) Regarding recharging time

Depending on the combination of the charger and

batteries, the charging time will become as shown in

Table 3

.

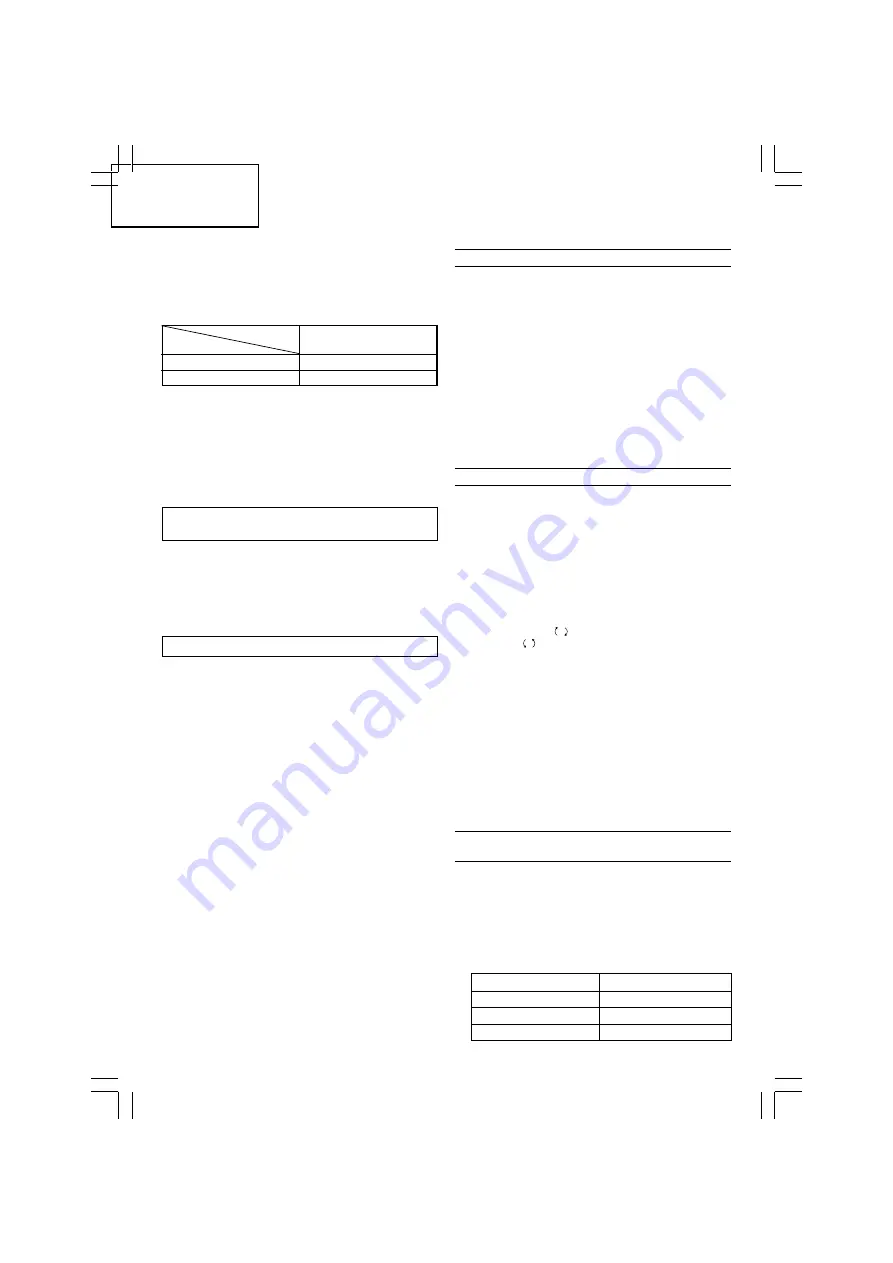

Table 3

Charging time (At 20°C)

NOTE:

The charging time may vary according to temperature

and power source voltage.

4. Disconnect the charger’s power cord from the

receptacle.

5. Hold the charger firmly and pull out the battery.

NOTE:

After operation, pull out batteries from the charger

first, and then keep the batteries properly.

Regarding electric discharge in case of new

batteries, etc.

As the internal chemical substance of new batteries

and batteries that have not been used for an extended

period is not activated, the electric discharge might

be low when using them the first and second time.

This is a temporary phenomenon, and normal time

required for recharging will be restored by recharging

the batteries 2 – 3 times.

How to make the batteries perform longer

(1) Recharge the batteries before they become completely

exhausted.

When you feel that the power of the tool becomes weaker,

stop using the tool and recharge its battery. If you continue

to use the tool and exhaust the electric current, the battery

may be damaged and its life will become shorter.

(2) Avoid recharging at high temperatures.

A rechargeable battery will be hot immediately after use.

If such a battery is recharged immediately after use, its

internal chemical substance will deteriorate, and the battery

life will be shortened. Leave the battery and recharge it

after it has cooled for a while.

CAUTION:

䡬

When the battery charger has been continuosly used, the

battery charger will be heated, thus constituting the cause

of the failures. Once the charging has been completed,

give 15 minutes rest until the next charging.

䡬

If the battery is recharged when it is warm due to battery

use or exposure to sunlight, the pilot lamp map light in

green.

The battery will not be recharged. In such a case, let the

battery cool before charging.

䡬

When the pilot lamp flickers in red (at 0.2-second intervals),

check for and take out any foreign objects in the charger’s

battery installation hole. If there are no foreign objects, it is

probable that the battery or charger is malfunctioning.

Take it to your authorized Service Center.

PRIOR TO OPERATION

1. Setting up and checking the work environment

Check if the work environment is suitable by following

the precautions.

2. Preparing the screws

Select screws appropriate to the application.

3. Bit checking and replacement

A No. 2 Plus bit is installed on this machine as a

standard accessory. Always inspect the bit to make

sure it is not damaged. Using worn bits can cause

screw-in malfunctions. Inspect the bit before work

and quickly replace it with a new one when it starts

to wear out. When the bit must be replaced due

to bit damage or any other reason, replace it

according to the instructions in Bit installation and

removal.

SWITCH ACTION (FIG. 4)

CAUTION

Before inserting the battery cartridge into the tool,

always check to see that the switch trigger actuates

properly and returns to the “OFF” position when

released.

To start the tool, simply pull the switch trigger. Release

the switch trigger to stop.

Reversing switch action (Fig. 5)

This tool has a reversing switch to change the

direction of rotation. Depress the reversing switch

lever from the

R

side for clockwise rotation or

from the

L

side for counterclockwise rotation.

When the reversing switch lever is in the neutral

position, the switch trigger cannot be pulled.

Pulling the switch trigger rotates the motor, but the

bit does not rotate. The bit rotates and tightens a

screw when the tip of the bit is pressed against

the groove on the screw head.

CAUTION

䡬

Always check the direction of rotation before

operation.

䡬

Use the reversing switch only after the tool comes to

a complete stop. Changing the direction of rotation

before the tool stops may damage the tool.

䡬

When not operating the tool, always set the reversing

switch lever to the neutral position.

ADJUSTING THE SCREW LENGTH AND

SCREW-IN DEPTH

1. Set the screw length (Fig. 6)

Set the screw length on this unit by sliding the guide

block.

(1) Slide the guide block while holding down the lever

and align the arrow on the guide block with the

number on the stopper to match the screw length.

(2) Find the screw length and screw guide position by

checking the table below.

STOPPER NUMBER

SCREW LENGTH

28

25 – 28 mm

32

32 – 35 mm

41

38 – 41 mm

Charger

UC18YRSL

Battery

BSL1430

Approx. 45 min.

BSL1840

Approx. 60 min.

01Eng_WF14DSL_WE.p65

12/18/12, 9:35 AM

11