English

13

4. When the slider won’t move smoothly

If the slider will not move smoothly, try cleaning the

sliding surfaces of the slider and slider case with an

air gun, etc. (

Fig. 17

).

NOTE

The unit tends to easily become covered with lath or

plaster board dust during jobs where it faces upwards.

Clean the sliding surfaces at regular periods during

the work task.

5. Attaching the sheet

If the sheet has been damaged and cannot be used,

please replace the sheet with attached one. Attach

the sheet by inserting the holes on the sheet on the

two protrusions on the stopper (

Fig. 18

).

6. Using the hook

The hook is used to hang up the power tool to your

waist belt while working.

CAUTION:

䡬

When using the hook, hang up the power tool firmly

not to drop accidentally.

If the power tool is dropped, it may lead to an accident.

䡬

When carrying the power tool with hooked to your

waist belt, do not fit any bit to the tip of power tool. If

the sharp bit such as drill is fitted to the power tool

when carrying it with hooked to your waist belt, you

will be injured.

䡬

Install securely the hook. Unless the hook is securely

installed, it may cause an injury while using.

(1) Removing the hook.

Remove the screws fixing the hook with Philips screw

driver. (

Fig. 19

)

(2) Replacing the hook and tightening the screws.

Install securely the hook in the groove of power tool

and tighten the screws to fix the hook firmly. (

Fig. 20

)

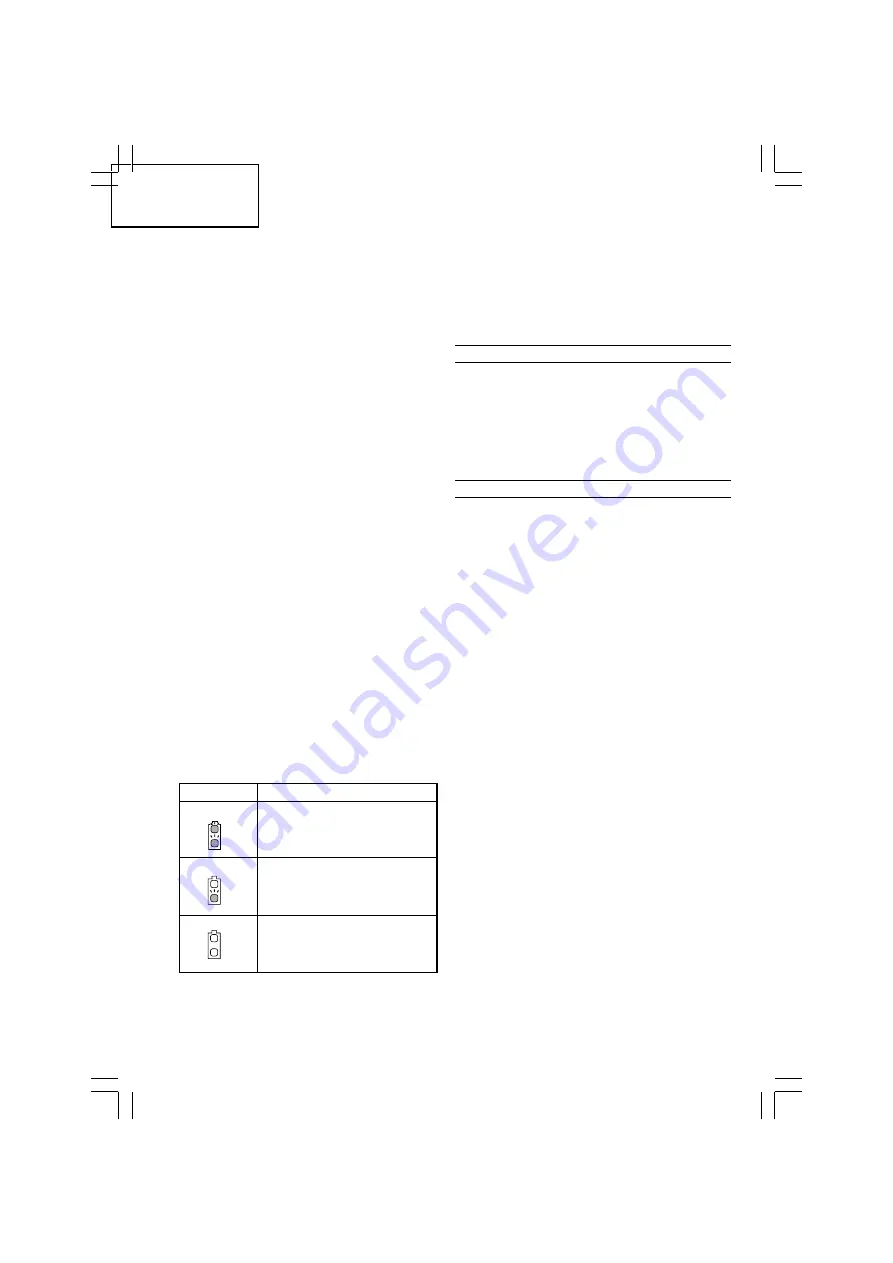

7. About Remaining Battery Indicator

When pressing the remaining battery indicator switch,

the remaining battery indicator lamp lights and the

battery remaining power can be checked. (

Fig.21

)

When releasing your finger from the remaining

battery indicator switch, the remaining battery

indicator lamp goes off. The table 4 shows the state

of remaining battery indicator lamp and the battery

remaining power.

As the remaining battery indicator shows somewhat

differently depending on ambient temperature and

battery characteristics, read it as a reference.

State of lamp Battery Remaining Power

The battery remaining power

is enough.

The battery remaining power

is a half.

The battery remaining power

is nearly empty.

Re-charge the battery soonest

possible.

Table 4

NOTE:

䡬

Do not give a strong shock to the switch panel or

break it.It may lead to a trouble.

䡬

To save the battery power consumption, the

remaining battery indicator lamp lights while pressing

the remaining battery indicator switch.

8. Confirm that the battery is mounted correctly

SCREW HANDLING

NOTE:

Handle both the packed box of screws and the collated

screw strips with care. If you drop them, screws can come

out of the collated tape and cause screw feed malfunctions.

Do not expose the screws to prolonged periods of direct

sunlight or outside air. They can cause rust and collated

tape problems, so when you will not be using the screws

for awhile, put them in the screw packing box or the like.

MAINTENANCE AND INSPECTION

1. Inspecting the driver bit

Using a broken bit or one with a worn out tip is

dangerous because the bit can slip. Replace it by

a new one.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Inspecting the carbon brushes (Fig. 22)

The motor employs carbon brushes which are

consumable parts. Since and excessively worn carbon

brush can result in motor trouble, replace the carbon

brush with new ones when it becomes worn to or

near the “wear limit”. In addition, always keep carbon

brushes clean and ensure that they slide freely whthin

the brush holders.

NOTE:

When replacing the carbon brush with a new one, be

sure to use the Hitachi Carbon Brush Code No. 999054.

5. Replacing carbon brushes

Take out the carbon brush by first removing the

brush cap and then hooking the protrusion of the

carbon brush with a flat head screw driver, etc., as

shown in

Fig. 24

.

When installing the carbon brush, choose the direction

so that the nail of the carbon brush agrees with the

contact portion outside the brush tube. Then push it

in with a finger as illustrated in

Fig. 25

. Lastly, install

the brush cap.

CAUTION:

Be absolutely sure to insert the nail of the carbon

brush into the contact portion outside the brush tube.

(You can insert whichever one of the two nails

provided).

Caution must be exercised since any error in this

operation can result in the deformed nail of the carbon

brush and may cause motor trouble at an early stage.

01Eng_WF14DSL_WE.p65

12/18/12, 9:35 AM

13