--- 10 -

--

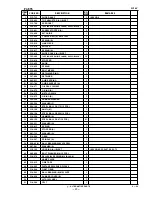

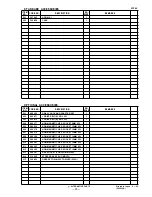

8. TROUBLESHOOTING

8-1. Troubleshooting Guide

Symptom

Screws protrude from the

workpiece surface.

Screw jamming.

Screws are not fed.

No.

1

2

3

Probable Cause

Faulty stopper adjustment.

Improper driver bit being used.

Driver bit excessively worn.

Thrust against workpiece is insufficient.

Screws other than those specified are used.

Strip contains defective screw(s).

Defective collating strip (deformed or cut).

Screws are missing.

<Collated screw strips>

Specified screws not used.

Defective screws used (bent screws, foreign

matter in slots of screw head, defective

collating).

Screws or collating tape are snagged or

scraping.

Collating tape is deformed or cut.

<Feeder unit>

Sprocket pawl is damaged.

Link piece is damaged.

Test

Turn knob counterclockwise and test drive

screw.

Check length of driver bit.

[Length = 114 mm (4-1/2")]

Check for wear at the face of the driver bit.

Check pressure during driving.

Check if specified screws are used.

Check if specified screws are properly

mounted.

Disassemble and check.

Remedy

Turn knob and adjust to correct scale setting.

Instruct operator to use genuine HITACHI

Driver Bits.

Replace driver bit.

Instruct operator to apply enough force to

engage screws and driver bits completely.

Use specified screws.

Replace defective screws.

Use specified screws.

Replace defective screws.

Replace defective parts.