--- 19 ---

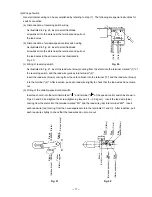

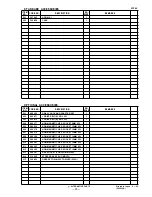

(8) Mounting position of the tapping screw

Note that the Belleville Springs M4 [43] and the Bolt Washers M4 [42] must be mounted together with the

Tapping Screws (W/Flange) D4 x 20 [13] at the positions specified in Fig. 25. Use only the Tapping Screws

(W/Flange) D4 x 20 [13] for the other positions.

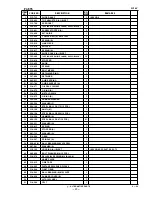

(9) Grease

Grease application spots

*MOLUB-ALLOY 777-1 (Code No. 309922) is recommended.

(a) Tooth surfaces of the Gear [37]

(b) Hammer (A) [31] lugs

(c) The Steel Balls [32] [3.97 mm dia. (5/32")]

(d) Spindle (A) [38] cam groove

(e) The sliding surface between Hammer (A) [31] and Spindle (A) [38]

(f) The 6 mm dia. hole in Anvil (M) [29]

(g) The sliding surface between Anvil (M) [29] and the Metal D20 x 16 [24]

(h) Hammer (A) [31] cam groove

(i) Spindle (A) [38] and Anvil (M) [29] or their splined portion

(j) The Steel Balls [30] [5.55 mm dia. (7/32")]

(k) Anvil (M) [29] vane

*Hitachi motor grease No. 29 [Code No. 930035 (tube) or 930037 (can)]

(l) Tooth surfaces of the Armature Ass'y [70] and First Gear [47]

(m) The Steel Balls [28] [3.175 mm dia. (1/8")] to be fitted into Anvil (M) [29]

(n) The sliding part of Guide Sleeve (A) [21] of Anvil (M) [29]

(o) The both side surfaces of the Ball Bearing [39] of the Gear [37]

(10) Tightening Torque

(a) Tapping Screws (W/Flange) [4] [13]

• • • • • • • • • • • • •

1.5 --- 2.5 N

•

m (15 --- 25 kgf

•

cm, 1.08 --- 1.80 ft-lb)

(b) Brush Cap [55]

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

0.5 --- 1.5 N

•

m (5 --- 15 kgf

•

cm, 0.36 --- 1.08 ft-lb)

Tapping screws (W/Flange)

D4 x 20

Specified positions

(6 pcs.)

Belleville spring M4

Bolt washer M4

Fig. 25