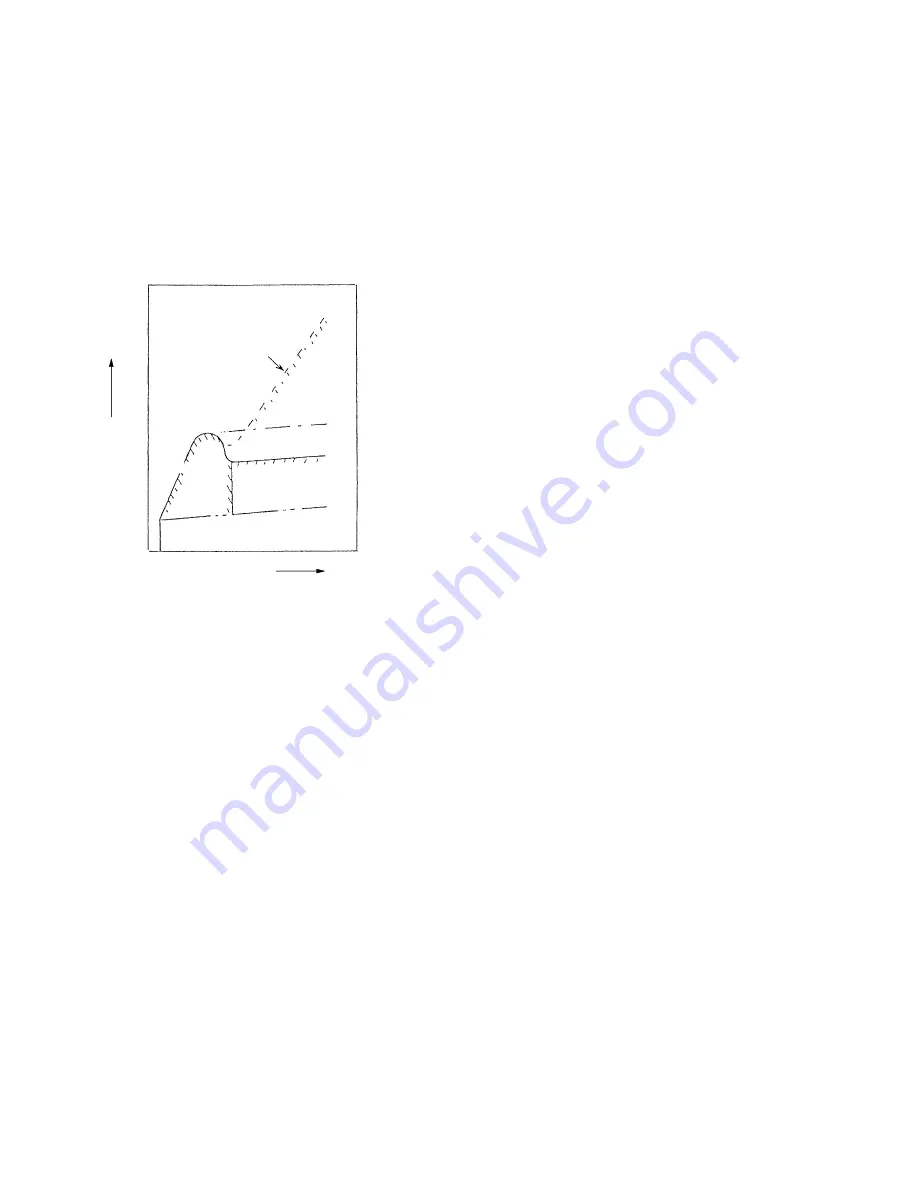

--- 2 ---

In Fig. 2, the solid line indicates the screw tightening load

applied with the impact mechanism, and the broken line a

typical load required with the conventional claw clutch system.

As the screw is tightened, tightening torque rises with the

screw's pushing into the work. Increasing downward pressure

is required when the screw slips off the tape because, on the

one hand, the clutch cannot be disengaged without such force

and on the other hand, the bit and the screw cannot be

separated apart otherwise. Both could be reasons for

incomplete driving when insufficient pressure is applied.

First referring to the claw clutch system, since the clutch

disengaging torque is strong, increasing pressure must be

applied to the screw as it is pushed in, because the clutch

claws would otherwise disengage, making further screw

tightening impossible. As a result, the required force goes on

rising, as indicated by the dotted line, until screw tightening is

finished.

Screw position

Load

4-1. Selling Point Descriptions

(1) An impact mechanism that allows screw tightening with a smaller thrust, plus our unique collated screw feed

attachment

The WF 4V employs an impact mechanism which is capable of tightening screws with a smaller thrust than

with the claw clutch system used for competitors' screwdrivers. The way it works is schematically illustrated

in Fig. 2.

With the impact system, on the contrary, it is sufficient to apply only enough force to keep the bit and screw

together, because hammering impact provides the necessary torque as the tightening torque increases, with

no need for the operator to increase pressure against the workpiece. The load indicated by solid line in Fig. 2

should be enough for optimum tightening. However, the actual load required will be such as indicated by the

chain line in Fig. 2 because it is very difficult for operators to take the force off as soon as the screw slips off

the tape.

(2) The WF 4V can be used as an impact screwdriver by removing the collated screw feed attachment:

For re-tightening jobs or other operations

Spring load

Pressure force of claw

clutch system

Pressure force of

impact mechanism

Slipping force

of tape

Fig. 2