-13-

5. Other precautions

(1) Check for cracks or other damage on the socket

Cracks or any other faults on the socket are very hazardous. In addition, cracks or other damage to the

accessories may cause loss of tightening torque efficiency. Advise the customers to check the

accessories periodically and ensure that there are no abnormalities.

(2) Socket dimensions

Be sure to use an appropriate socket that matches the bolt and/or nut dimensions. If the socket

dimensions are larger than the bolts or nuts, the tightening torque may be decreased and the socket

may be easily damaged. Please refer to the table in page 4 for appropriate socket dimensions.

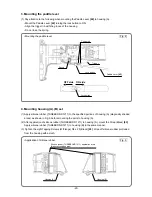

(3) Lubrication of hammering section

Frequent or continuous use of the tool may cause excessive temperature rise of the hammering section,

resulting in depletion of grease and subsequent wear of the components which may, in turn, cause loss

of tightening efficiency. Accordingly, it is necessary to periodically replenish grease in the hammering

section to ensure proper lubrication of the moving and sliding components.

(4) Precaution against impact and water

Do not give a strong impact on the Models WH 14DCAL and WH 14DY such as dropping or do not wet

them with water because precision components are incorporated in them. Otherwise, a malfunction will

occur.