-6-

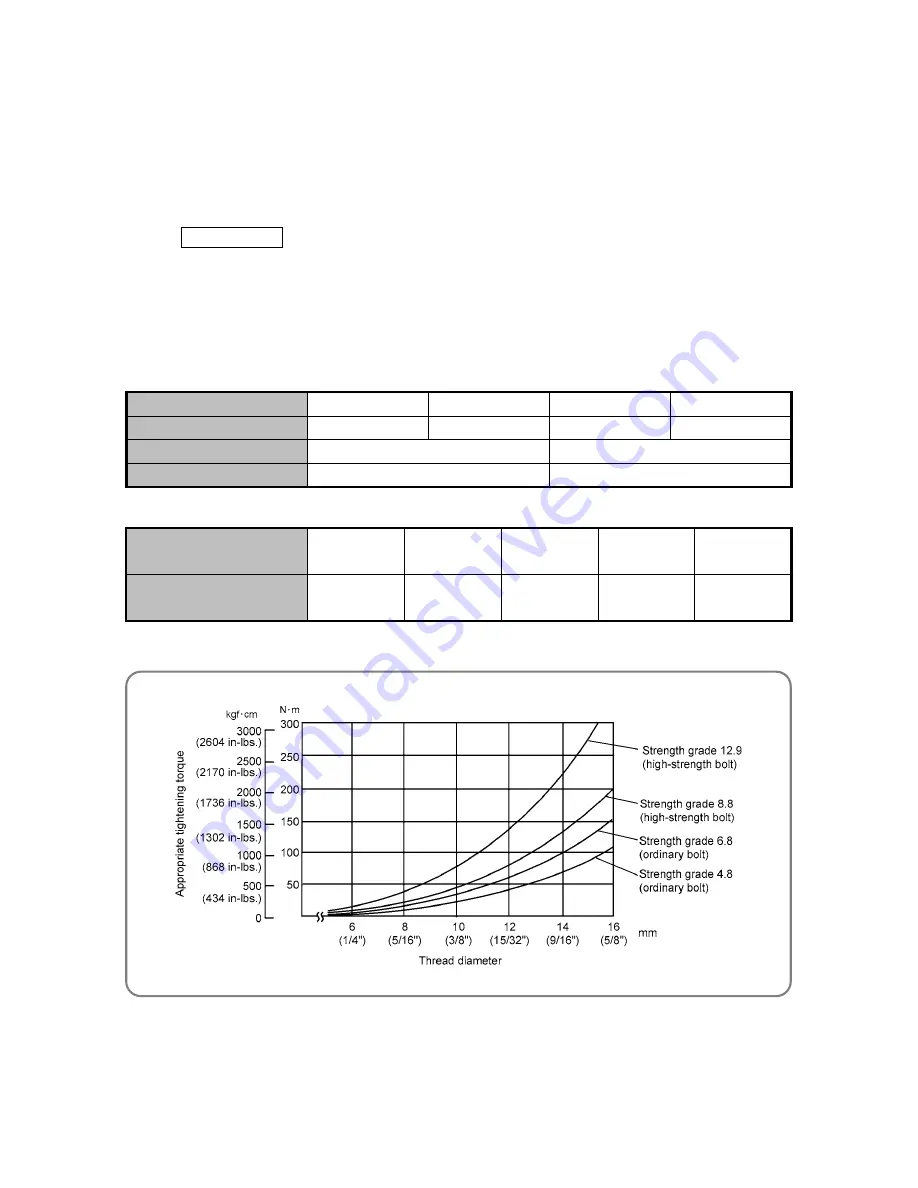

2. Tightening torque

(1) Diameter of thread and appropriate tightening torque

Generally speaking, the appropriate tightening torque for a screw can be determined by the strength

grade of the screw and the material tightened. The tables below list data relative to the strength grade of

various screws and the appropriate tightening torque. For further reference, appropriate tightening

torque is calculated with the following formula. Study and use this formula for accurate selection of

tightening torque.

T = k

•

d

•

p

T: Appropriate tightening torque (kgf

•

cm)

d: Nominal diameter of thread (mm)

p: Recommended axial tightening force to be applied to the screw (kgf)

p = Rated axial stress (kgf/cm

2

) x 0.8 x Effective sectional area of the thread (mm

2

)

k: Torque coefficient (0.17)

• Strength grade and rated axial stress of thread

Strength grade

4.8

6.8

8.8

12.9

Rated axial stress (kgf/mm

2

)

29.1

43.7

58.2

95

Material

Mild steel

Alloy steel including Ni, Mn, Cr, etc.

Heat treatment

Not processed

Precessed: Hard material

• Diameter and effective sectional area of thread

Kind of thread (x pitch)

M5 x 0.8 mm

(3/16”)

M6 x 1 mm

(1/4”)

M8 x 1.25 mm

(5/16”)

M10 x 1.5 mm

(3/18”)

M12 x 1.75 mm

(15/32”)

Effective section area

of thread (mm

2

)

14.2

20.1

36.6

58.0

84.3

• Diameter of thread and appropriate tightening torque