25

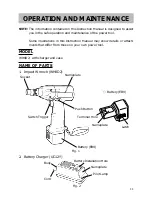

MAINTENANCE AND INSPECTION

CAUTION: Pull out battery before doing any inspection or maintenance.

1. Checking the condition of the socket.

A worn or deformed hex or a square-holed socket will not give an adequate

tightness to the fitting between the nut or anvil, consequently resulting in loss of

tightening torque. Pay attention to wear of a socket holes periodically, and

replace with a new one if needed.

2

Check the Mounting Screws

Loose mounting screws are dangerous. Regularly inspect them and make sure

they are tight.

CAUTION: Using this power tool with loosen, screws is extremely dangerous.

3

Check for Dust

Dust may be removed with a soft cloth or a cloth dampened with soapy water.

Do not use bleach, chlorine, gasoline or thinner, for they may damage the

plastics.

STORAGE

Storing in a place below 104°F (40°C) and out of the reach of children.

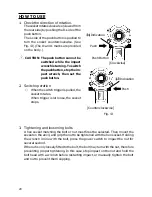

SERVICE AND REPAIRS

All quality power tools will eventually require servicing or replacement of parts

because of wear from normal use. To assure that only authorized replacement parts

will be used, all service and repairs must be performed by a HITACHI AUTHORIZED

SERVICE CENTER, ONLY.

NOTE:

Specifications are subject to change without any obligation on the part of the

HITACHI.

!

!

Summary of Contents for WH 8D2

Page 26: ...26 ...