--- 22 ---

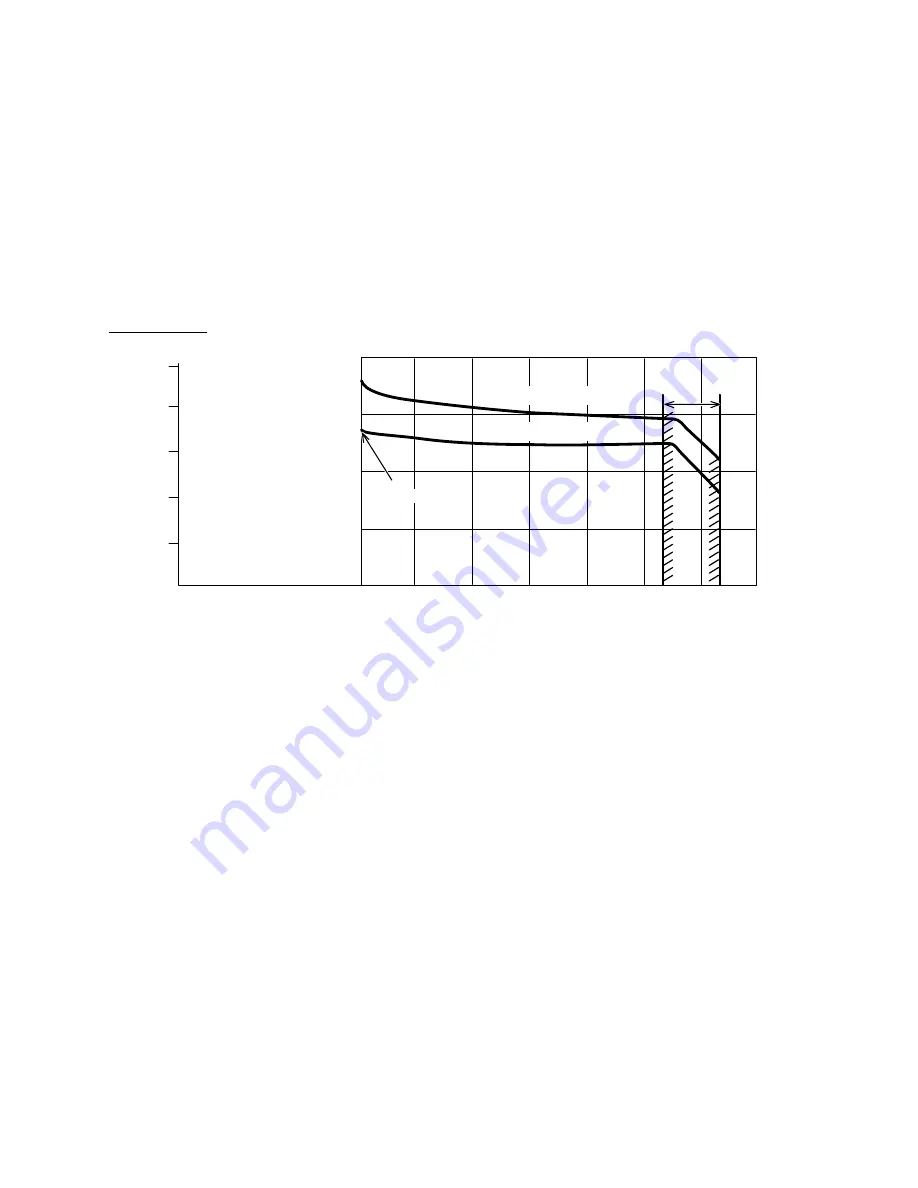

(1) Voltage of battery

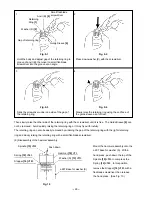

Tightening torque is affected by the voltage output of the battery. For example, the relationship between

tightening torque and the number of M12 x 45 mm (15/32" x 1-3/4") high-strength bolts tightened is shown in

Fig. 8 below. As can be seen in the graph, tightening torque decreases as the number of bolts tightened

increases. This phenomenon is caused by the decline in voltage output of the battery due to the increasing

number of bolts tightened. In particular, the tightening torque decreases rapidly just before the battery is fully

discharged (range "a" in the graph). As this phenomenon is an inherent drawback in any cordless impact

driver, salespersons are requested to ensure that the customer is fully aware of and understands this

characteristic.

Model WR 8DH

Fig. 8

(2) Effects of low ambient temperatures

The tightening torque required may be reduced at low ambient temperatures or under the influence of grease

and different torque coefficients (dependent on manufacturing and finishing processes, and specified by bolt

manufacturers).

(3) Different bolt diameter

Differences in bolt diameter will cause variation of the required levels of tightening torque. Generally speaking,

tightening torque is higher for large bolts.

(4) Different materials being tightened

When a bolt is tightened into a soft material such as aluminum, plastic, wood, etc., the tightening torque is

considerably less than when the bolt is tightened into a hard material such as steel.

(5) Different tightening conditions

The tightening torque may vary in accordance with bolt torque coefficient (dependent on manufacturing

process, and specified by bolt manufactures), bolt grade and bolt length, even though the dimensions of the

bolts are the same. Tightening torque may also vary depending on the surface finishing state of tightening

materials (steel, aluminum, etc.), and materials to be tightened. In addition, if there is seal packing, clearance,

etc., between tightening materials, the tightening torque is decreased.

Fully charged

a

Battery voltage

Tightening torque

M12 x 45 mm (15/32" x 1-3/4") high-strength bolt (tightening time: 3 seconds)

400

(39.2 N

•

m, 29 ft-lbs)

800

(78.4 N

•

m, 58 ft-lbs)

1,200

(117.6 N

•

m, 86 ft-lbs)

0

2

4

6

8

10

20

40

60

80

100

120

Number of screws driven per charge (EB 9B battery)

Tightening torque

Batter

y v

oltage

(pcs.)

(kgf

•

cm)

(V)

Summary of Contents for WH 8DH

Page 35: ... 32 Assembly Diagram for WH 8DH ...