--- 6 ---

Charger power source: Single-phase AC, 50/60 Hz

Voltage: Depending on the order specification

Power input: 56 W

Charging system: Constant current charge with feedback control

Overcharge protection system: (1) Battery voltage detection (

2

V system)

Battery temperature detection (dT/dt system)

for Ni-MH battery

(2) Battery surface temperature detection

(thermistor)

(3) 120-minute timer

Output voltage: 7.2 V --- 14.4 V

Output current: 2.6 A

Charging time: Approx. 50 minutes (for type EB 9B battery at 20

û

C)

Approx. 60 minutes (for type EB 926H battery at 20

û

C)

Approx. 70 minutes (for type EB 930H battery at 20

û

C)

Product weight: 0.6 kg

Operable ambient temperature range: 0

û

C --- 40

û

C

The maximum allowable temperature of the EB 9B type battery is 55

û

C and the

EB 926HL or EB 930H type battery is 45

û

C.

Charger (For UC 14YFA)

Sealed cylindrical nickel-cadmium batteries

Nominal voltage: DC 9.6 V

Nominal life: Charging/discharging approximately 300 cycles (in the case of Model

UC 18YG)

Nominal capacity: 2.0 Ah

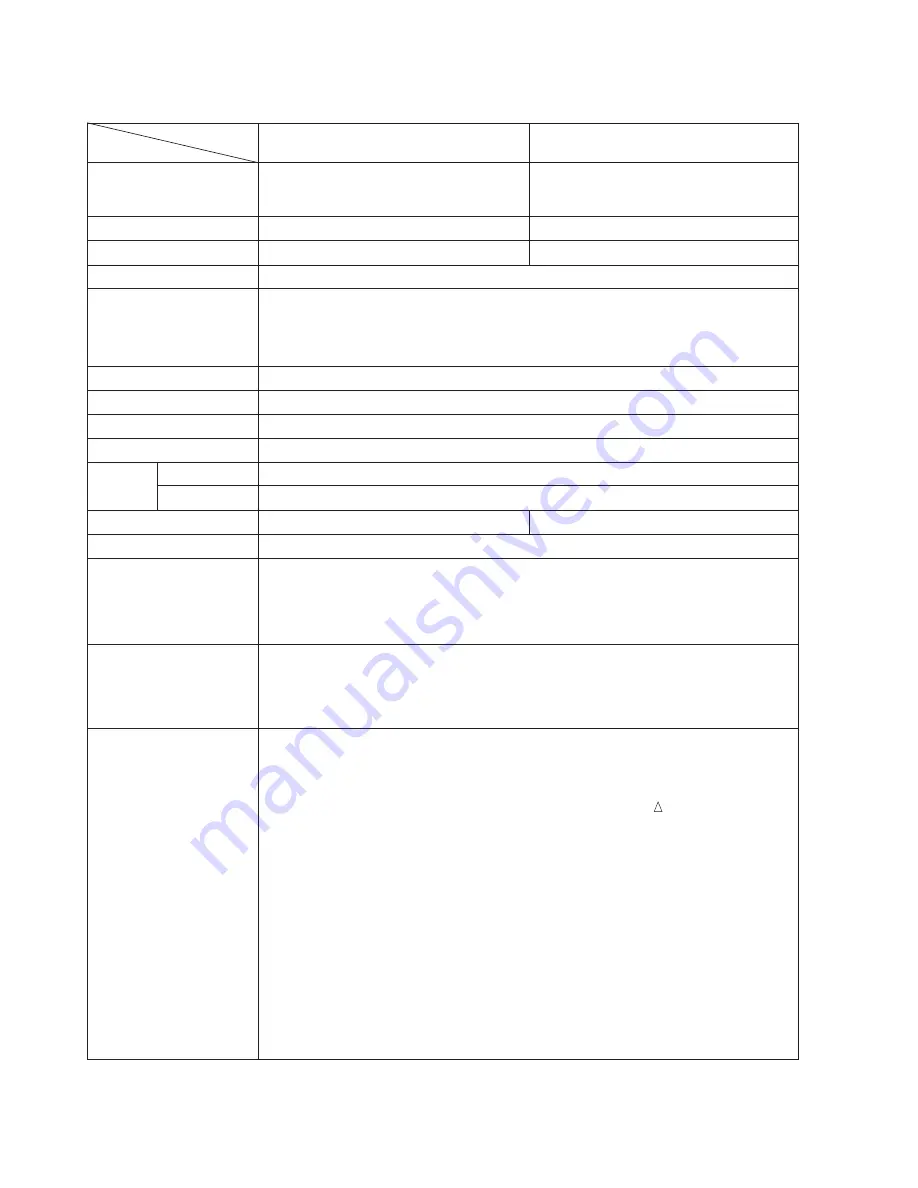

6. SPECIFICATIONS

6-1. Specifications

Model

Cordless impact driver

WH 9DMR

Capacity

Item

Cordless impact wrench

WR 9DMR

Small screw M4 --- M8 (5/32" --- 5/16")

*

1

Ordinary bolt M5 --- M12 (3/16" --- 15/32")

High-strength bolt M5 --- M10 (3/16" --- 25/64")

Ordinary bolt M6 --- M14 (1/4" --- 9/16")

High-strength bolt M6 --- M10 (1/4" --- 3/8")

Tightening torque

105 N

•

m (1070 kgf

•

cm, 930 in-lbs.)*

2

115 N

•

m (1170 kgf

•

cm, 1020 in-lbs.)*

3

Tip condition

6.35 mm (1/4") Bit holder

9.5 mm (3/8") Square drive

Type of motor

Fan cooled DC magnet motor

Enclosure

Main body: Polyamide resin

• • • • • •

Housing

Aluminum alloy die casting

• • • • • •

Hammer case

Storage battery: ABS resin (black)

Charger: ABS resin (black)

Type of switch

Trigger switch with forward/reverse changeover pushing button (with brake and variable)

Handle configuration

T-type

No-load rotational speed

0 --- 2,600 /min

Impact rate

0 --- 3,200 /min

Main body

1.4 kg (3.0 lbs.)

Battery

0.55 kg (1.2 lbs.)

Overall length x height

155 mm (6-7/64") x 223 mm (8-25/32")

Center height

26.5 mm (1-3/64")

Battery (Type EB 9B)

160 mm (6-19/64") x 223 mm (8-25/32")

Battery (Type EB 926H/

EB 930H)

Sealed cylindrical nickel-metal hydride batteries

Nominal voltage: DC 9.6 V

Nominal life: Charging/discharging approximately 500 cycles (in the case of Model

UC 14YFA)

Nominal capacity: 2.6 Ah/3.0 Ah

Weight