--- 18 ---

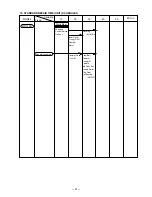

(2) Effects of low ambient temperatures

The tightening torque required may be reduced at low ambient temperatures or under the influence of grease

and different torque coefficients (dependent on manufacturing and finishing processes, and specified by bolt

manufacturers).

(3) Different bolt diameter

Differences in bolt diameter will cause variation of the required levels of tightening torque. Generally speaking,

tightening torque is higher for large bolts.

(4) Different materials being tightened

When a bolt is tightened into a soft material such as aluminum, plastic, wood, etc., the tightening torque is

considerably less than when the bolt is tightened into a hard material such as steel.

(5) Different tightening conditions

The tightening torque may vary in accordance with bolt torque coefficient (dependent on manufacturing

process, and specified by bolt manufactures), bolt grade and bolt length, even though the dimensions of the

bolts are the same. Tightening torque may also vary depending on the surface finishing state of tightening

materials (steel, aluminum, etc.), and materials to be tightened. In addition, if there is seal packing, clearance,

etc., between tightening materials, the tightening torque is decreased.

(6) Wear and looseness of the socket

With extended use, the hexagonal portion of the socket which is fitted to the head of the bolt and/or hexagonal

portion of the socket which is fitted onto the anvil in the main body will become worn and loose. Wear and

looseness will cause a proportionate loss of tightening torque. In addition, use of an incorrect size socket

(slightly larger than the bolt being tightened) will also result in decreased torque.

(7) Bolt and nut rotate together

Tightening torque that can be achieved will be considerably decreased if the bolt and nut rotate together

during the tightening operation. The customer should be advised to carefully observe the operation and

ensure this does not occur.

7-4. Suggestions and Precautions for the Efficient Use of the Charger

(1) Batteries may not be rechargeable immediately after use

If the type EB 14B or EB 1430H Storage Batteries are exposed to direct sunshine for an extended period, or if

the temperature of the batteries is 40˚C (104˚F) or higher immediately after they have been used in the tool,

the pilot lamp may not light up when the batteries are connected to the Model UC 14YF2 Charger. This is

because the built-in thermostat functions to stop the charging when the temperature of the storage batteries

reach 40˚C (104˚F) or more. In such a case, the customer should be advised to place the batteries in a

shaded area with a good airflow, and allow sufficient cooling before recharging.

This phenomenon is common to all existing batteries which employ temperature sensitive overcharge devices.

The cooling time required before charging can be accomplished varies from a few minutes to about 30

minutes, depending on the load, duration of use, and ambient temperatures.