English

8

○

When

the

pilot

lamp

fl

ickers

in

red

(at

0.2-second

intervals),

check

for

and

take

out

any

foreign

objects

in

the

charger’s

battery

installation

hole.

If

there

are

no

foreign

objects,

it

is

probable

that

the

battery

or

charger

is

malfunctioning.

Take

it

to

your

authorized

Service

Center.

PRIOR TO OPERATION

1. Preparing and checking the work environment

Make

sure

that

the

work

site

meets

all

the

conditions

laid

forth

in

the

precautions.

2. Checking the battery

Make

sure

that

the

battery

is

installed

fi

rmly.

If

it

is

at

all

loose

it

could

come

o

ff

and

cause

an

accident.

3. Selecting the socket matched to the bolt

Be

sure

to

use

a

socket

which

is

matched

to

the

bolt

to

be

tightened.

Using

an

improper

socket

will

not

only

result

in

insu

ffi

cient

tightening

but

also

in

damage

to

the

socket

or

nut.

A

worn

or

deformed

hex.

or

square-holed

socket

will

not

give

an

adequate

tightness

for

fi

tting

to

the

nut

or

anvil,

consequently

resulting

in

loss

of

tightening

torque.

Pay

attention

to

wear

of

socket

hole,

and

replace

before

further

wear

has

developed.

4. Installing a socket

Select

the

socket

to

be

used.

●

Pin,

O-ring

type

(1)

Align

the

hole

in

the

socket

with

the

hole

in

the

anvil

and

insert

the

anvil

into

the

socket.

(2)

Insert

the

pin

into

the

socket.

(3)

Attach

the

ring

to

the

groove

on

the

socket.

●

Plunger

type

Align

the

plunger

located

in

the

square

part

of

the

anvil

with

the

hole

in

the

hex.

socket.

Then

push

the

plunger,

and

mount

the

hex.

socket

on

the

anvil.

Check

that

the

plunger

is

fully

engaged

in

the

hole.

When

removing

the

socket,

reverse

the

sequence.

●

Retaining

ring

type

(1)

Align

the

square

portions

of

the

socket

and

the

anvil

with

each

other.

(2)

Make

sure

to

fi

rmly

install

the

socket

by

pushing

it

all

the

way

into

the

anvil.

(3)

When

removing

the

socket,

pull

it

out

of

the

anvil.

CAUTION

○

Please

use

the

designated

attachments

which

are

listed

in

the

operations

manual

and

Hitachi’s

catalog.

Accidents

or

injuries

could

result

from

not

doing

so.

○

Make

sure

to

fi

rmly

install

the

socket

in

the

anvil.

If

the

socket

is

not

fi

rmly

installed

it

might

come

out

and

cause

injuries.

HOW TO USE

1. Operation of switch

The

switch

in

this

machine

functions

as

a

motor

switch

and

rotational

direction

selector

switch.

When

the

switch

is

set

to

indicated

on

the

handle,

the

motor

rotates

clockwise

to

tighten

the

bolt.

When

the

switch

is

set

to

,

the

motor

rotates

counterclockwise

to

loosen

the

bolt.

When

the

switch

is

released,

the

motor

stops.

(

Fig. 6

)

CAUTION

Be

sure

to

turn

the

switch

OFF

and

wait

until

the

motor

completely

stops

before

changing

the

direction

of

wrench

revolution.

Switching

while

the

motor

is

rotating

will

result

in

burning

the

motor.

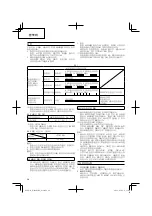

2. About Remaining Battery Indicator

When

pressing

the

remaining

battery

indicator

switch,

the

remaining

battery

indicator

lamp

lights

and

the

battery

remaining

power

can

be

checked.

(

Fig. 7

)

When

releasing

your

fi

nger

from

the

remaining

battery

indicator

switch,

the

remaining

battery

indicator

lamp

goes

o

ff

.

The

Table 4

shows

the

state

of

remaining

battery

indicator

lamp

and

the

battery

remaining

power.

Table 4

State

of

lamp Battery

Remaining

Power

The

battery

remaining

power

is

enough.

The

battery

remaining

power

is

a

half.

The

battery

remaining

power

is

nearly

empty.

Re-charge

the

battery

soonest

possible.

As

the

remaining

battery

indicator

shows

somewhat

di

ff

erently

depending

on

ambient

temperature

and

battery

characteristics,

read

it

as

a

reference.

NOTE:

○

Do

not

give

a

strong

shock

to

the

switch

panel

or

break

it.

It

may

lead

to

a

trouble.

○

To

save

the

battery

power

consumption,

the

remaining

battery

indicator

lamp

lights

while

pressing

the

remaining

battery

indicator

switch.

3. How to use the LED light

Every

time

you

press

the

light

switch

on

the

switch

panel,

the

LED

light

lights

or

goes

o

ff

.

(

Fig. 8

)

To

prevent

the

battery

power

consumption,

turn

o

ff

the

LED

light

frequently.

CAUTION

Do

not

expose

directly

your

eye

to

the

light

by

looking

into

the

light.

If

your

eye

is

continuously

exposed

to

the

light,

your

eye

will

be

hurt.

NOTE:

To

prevent

the

battery

power

consumption

caused

by

forgetting

to

turn

o

ff

the

LED

light,

the

light

goes

o

ff

automatically

in

about

15

minutes.

4. Tightening and loosening bolts

A

hex.

socket

matching

the

bolt

or

nut

must

fi

rst

be

selected.

Then

mount

the

socket

on

the

anvil,

and

grip

the

nut

to

be

tightened

with

the

hex.

socket.

Holding

the

wrench

in

line

with

the

bolt,

press

the

power

switch

to

impact

the

nut

for

several

seconds.

If

the

nut

is

only

loosely

fi

tted

to

the

bolt,

the

bolt

may

turn

with

the

nut,

therefore

mistaking

proper

tightening.

In

this

case,

stop

impact

on

the

nut

and

hold

the

bolt

head

with

a

wrench

before

restarting

impact,

or

manually

tighten

the

bolt

and

nut

to

prevent

them

slipping.

OPERATIONAL CAUTIONS

1. Resting the unit after continuous work

After

use

for

continuous

bolt-tightening

work,

rest

the

unit

for

15

minutes

or

so

when

replacing

the

battery.

The

temperature

of

the

motor,

switch,

etc.,

will

rise

if

the

work

is

started

again

immediately

after

battery

replacement,

eventually

resulting

in

burnout.

NOTE:

Do

not

touch

the

metal

parts,

as

it

gets

very

hot

during

continuous

work.

2. Work at a tightening torque suitable for the bolt

under impact

The

optimum

tightening

torque

for

nuts

or

bolts

di

ff

ers

with

material

and

size

of

the

nuts

or

bolts.

An

excessively

large

tightening

torque

for

a

small

bolt

may

stretch

or

break

the

bolt.

The

tightening

torque

increases

in

proportion

to

the

operation

time.

Use

the

correct

operating

time

for

the

bolt.

000Book̲WR18DSHL̲Ara.indb 8

000Book̲WR18DSHL̲Ara.indb 8

2012/07/16 9:20:58

2012/07/16 9:20:58