MAINTENANCE

7-13

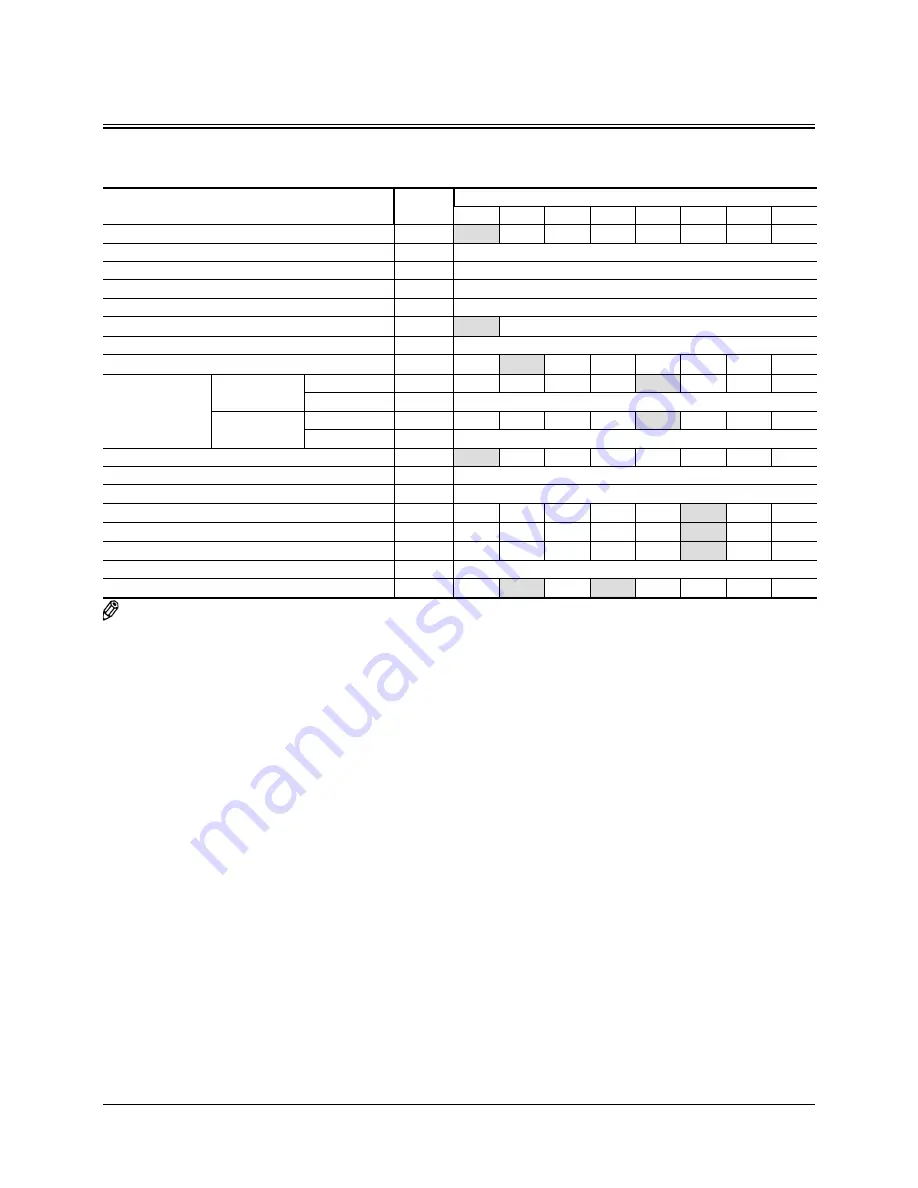

H. ELECTRICAL SYSTEM (See Page 7-62)

I. MISCELLANEOUS (See Page 7-68)

Parts

Quantity

Interval (hours)

8

50

100

250

500

1000

2000

4000

1. Check Bucket Teeth for Wear and Looseness

—

2. Change Bucket

—

As required

3. Convert Bucket Connection Into Face Shovel

—

As required

4. Adjust Bucket Linkage

1

As required

5. Remove Travel Levers

2

As required

6. Check and Replace Seat Belt

1

Every 3 years (Replace)

7. Check Windshield Fluid Level

1

As required

8. Check Track Sag

2

9. Check Air

Conditioner

Filter (Opt.)

Circulating Air

Filter

Cleaning

1

Replacement

1

After cleaning 6 times or so

Fresh Air Filter

Cleaning

1

Replacement

1

After cleaning 6 times or so

10. Check Air Conditioner (Opt.)

—

11. Clean Cab Floor

—

As required

12. Retighten Cylinder Head Bolt

—

✸

As required

13. Inspect and Adjust Valve Clearance

—

✸

14. Measure Engine Compression Pressure

—

✸

15. Check Starter and Alternator

—

✸

16. Check and Replace EGR Device

—

✸

As required

17. Check Tightening Torque of Bolts and Nuts

—

★★

NOTE:

✸

Contact your authorized dealer for maintenance.

★★

Maintenance required only during first time check.

Summary of Contents for ZAXIS 120-3 class

Page 1: ......

Page 3: ......

Page 5: ......

Page 49: ...SAFETY SIGNS Europe Asia Middle and Near East Model Only S 38 MEMO ...

Page 131: ...BREAK IN 2 MEMO ...

Page 191: ...TRANSPORTING 6 MEMO ...

Page 290: ...HYDRAULIC CIRCUIT AND ELECTRICAL CIRCUIT 8 HYDRAULIC CIRCUIT M1V1 08 001 ...

Page 292: ...8 ELECTRICAL DIAGRAM ...

Page 293: ...HYDRAULIC CIRCUIT AND ELECTRICAL CIRCUIT 8 MEMO ...

Page 295: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 MEMO ...

Page 351: ...SPECIFICATIONS 12 42 MEMO ...

Page 455: ...OPTIONAL ATTACHMENTS AND DEVICES 13 104 MEMO ...

Page 461: ...INDEX 14 MEMO ...