MAINTENANCE

7-18

2

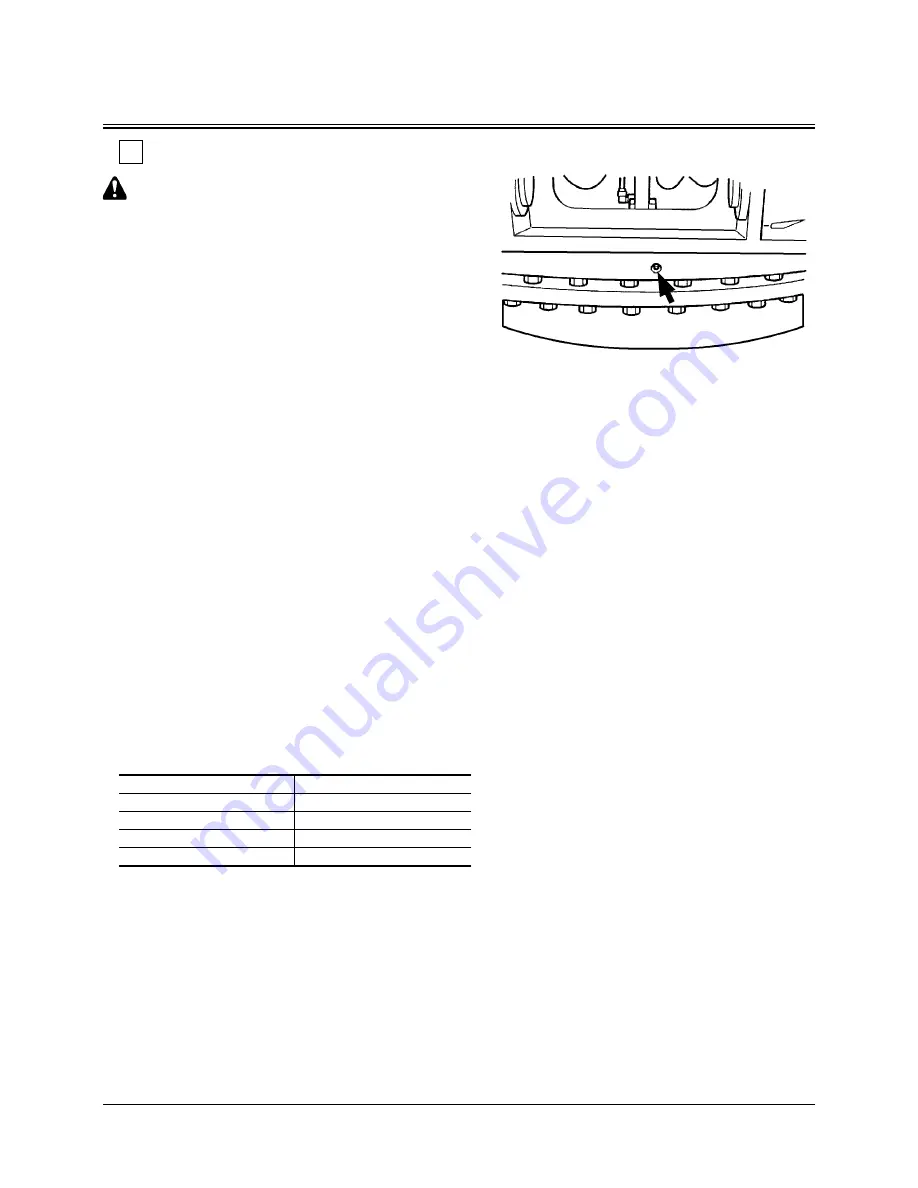

Swing Bearing --- every 500 hours

CAUTION: Lubricating both the swing bearing and

gear and rotating the upperstructure must be done

by one person. Before you lubricate the swing bear-

ing, clear the area of all persons.

Each time you leave the cab

•

Lower the bucket to the ground.

•

Stop the engine.

•

Pull the pilot control shut-off lever to the LOCK

position.

•

Use handrails.

1. Park the machine on a level surface.

2. Lower the bucket to the ground.

3. Turn the auto-idle switch off.

IMPORTANT: The turbocharger may be damaged if the

engine is not properly shut down.

4. Run the engine at slow idle speed without load for five

minutes.

5. Turn the key switch OFF. Remove the key from the key

switch.

6. Pull the pilot control shut-off lever to the LOCK position.

7. With the upperstructure stationary, apply grease via the

two grease fittings.

8. Start the engine. Raise the bucket several inches off the

ground and rotate the upperstructure 45° (1/8 turn).

9. Lower the bucket to the ground.

10. Repeat the procedure three times, beginning with step 3.

11. Apply grease to the swing bearing until grease can be

seen escaping from the swing bearing seals.

Model

Capacity

ZX120-3 Class

0.25 L (0.26 US qt)

ZX180-3, 200-3 Class

0.30 L (0.32 US qt)

ZX270-3 Class

0.35 L (0.37 US qt)

ZX330-3 Class

0.40 L (0.42 US qt)

12. Take care not to supply excessive grease.

M157-07-159

Summary of Contents for ZAXIS 120-3 class

Page 1: ......

Page 3: ......

Page 5: ......

Page 49: ...SAFETY SIGNS Europe Asia Middle and Near East Model Only S 38 MEMO ...

Page 131: ...BREAK IN 2 MEMO ...

Page 191: ...TRANSPORTING 6 MEMO ...

Page 290: ...HYDRAULIC CIRCUIT AND ELECTRICAL CIRCUIT 8 HYDRAULIC CIRCUIT M1V1 08 001 ...

Page 292: ...8 ELECTRICAL DIAGRAM ...

Page 293: ...HYDRAULIC CIRCUIT AND ELECTRICAL CIRCUIT 8 MEMO ...

Page 295: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 MEMO ...

Page 351: ...SPECIFICATIONS 12 42 MEMO ...

Page 455: ...OPTIONAL ATTACHMENTS AND DEVICES 13 104 MEMO ...

Page 461: ...INDEX 14 MEMO ...