MAINTENANCE

7-39

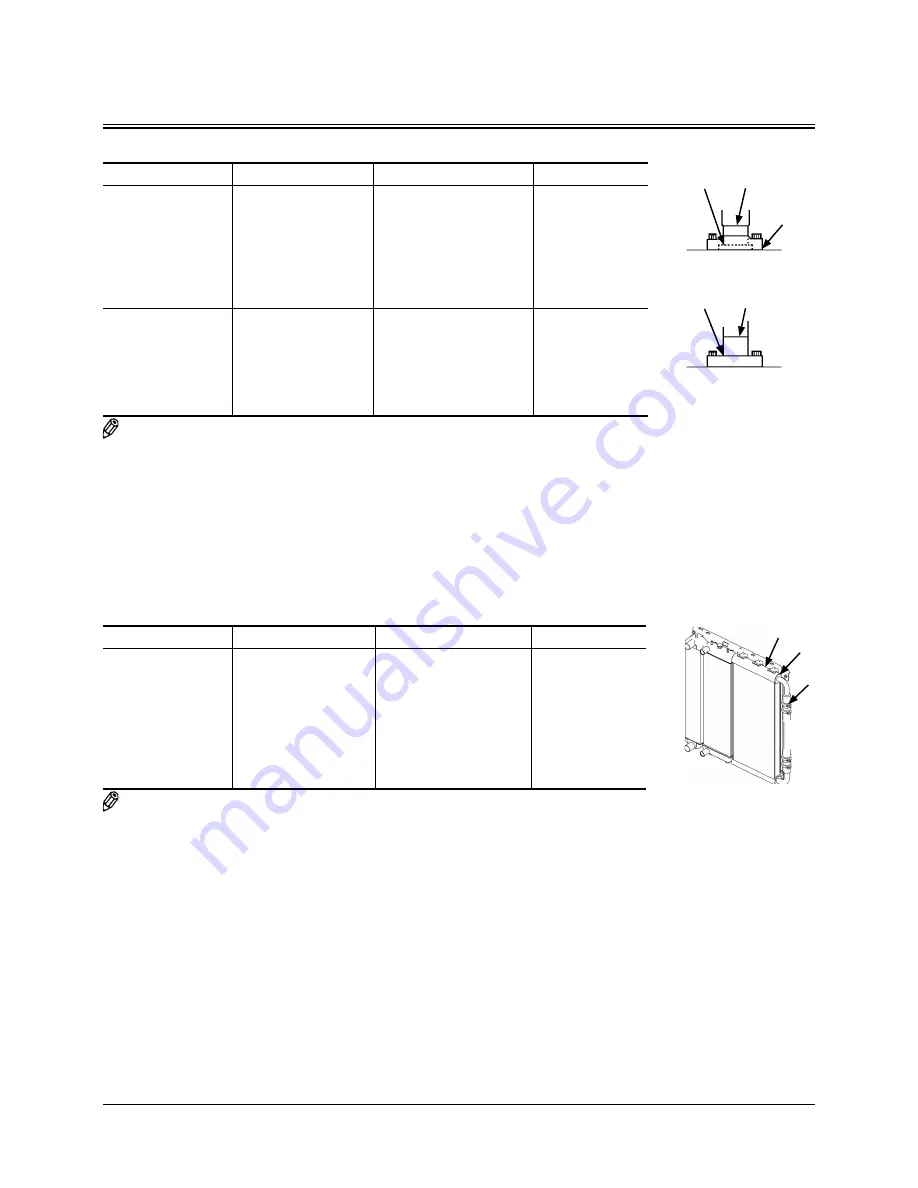

Table 2. Lines

Interval (hours)

Check Points

Abnormalities

Remedies

Daily

Contact surfaces of

flange joints

Welded surfaces on

joints

Leak (11)

Leak (12)

Replace

O-ring

and/or

retighten bolts

Replace

Every 250 hours

Joint neck

Welded surfaces

on joints

Clamps

Crack (13)

Crack (12)

Missing

Deformation

Loose

Replace

Replace

Replace

Replace

Retighten

NOTE: Refer to the illustrations in Fig.2 for each check point location or for a description of the

abnormality. Use genuine Hitachi parts

Table 3. Oil cooler

Interval (hours)

Check Points

Abnormalities

Remedies

Every 250 hours

Contact surfaces of

flange joints

Oil cooler

Coupling and

rubber hose

Leak (14)

Leak (15)

Leak (16)

Replace

O-ring

and/or

retighten bolts

Replace

Retighten or

replace

NOTE: Refer to the illustrations in Fig.3 for each check point location.

Fig. 2

M137-07-001

13

12

11

M137-07-007

13

12

Fig. 3

M1U1-07-051

14

15

16

Summary of Contents for ZAXIS 120-3 class

Page 1: ......

Page 3: ......

Page 5: ......

Page 49: ...SAFETY SIGNS Europe Asia Middle and Near East Model Only S 38 MEMO ...

Page 131: ...BREAK IN 2 MEMO ...

Page 191: ...TRANSPORTING 6 MEMO ...

Page 290: ...HYDRAULIC CIRCUIT AND ELECTRICAL CIRCUIT 8 HYDRAULIC CIRCUIT M1V1 08 001 ...

Page 292: ...8 ELECTRICAL DIAGRAM ...

Page 293: ...HYDRAULIC CIRCUIT AND ELECTRICAL CIRCUIT 8 MEMO ...

Page 295: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 MEMO ...

Page 351: ...SPECIFICATIONS 12 42 MEMO ...

Page 455: ...OPTIONAL ATTACHMENTS AND DEVICES 13 104 MEMO ...

Page 461: ...INDEX 14 MEMO ...