MAINTENANCE

7-40

SERVICE RECOMMENDATIONS FOR HYDRAULIC

FITTINGS

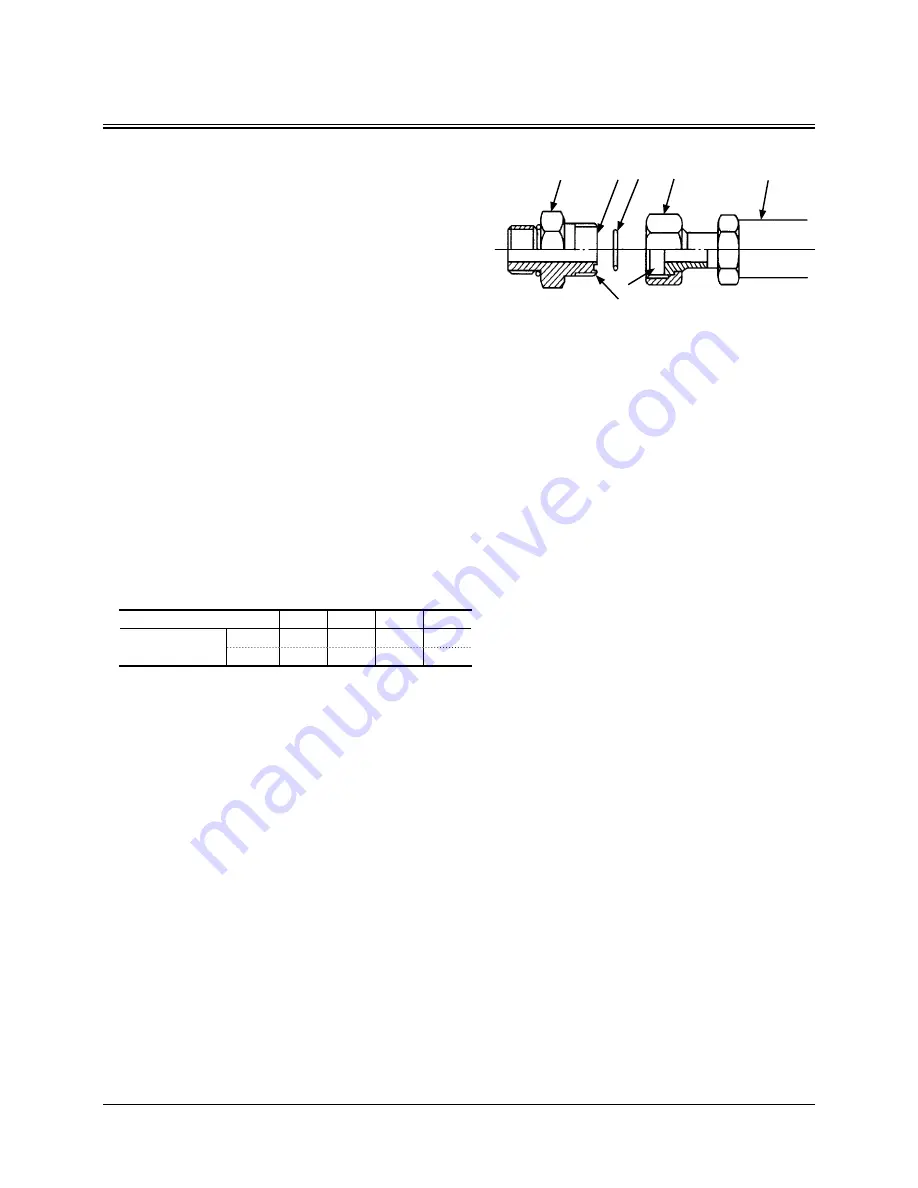

Two hydraulic fitting designs are used on this machine.

Flat Face O-ring Seal Fitting (ORS Fitting)

An O-ring is used on the sealing surfaces to prevent oil leak-

age.

1. Inspect fitting sealing surfaces (6). They must be free of

dirt or defects.

2. Replace O-ring (1) with a new one when assembling fit-

ting (2).

3. Lubricate O-ring (1) and install it into groove (3) using

petroleum jelly to hold it in place.

4. Tighten fitting (2) by hand, pressing the fitting joint

together to ensure O-ring (1) remains in place and is not

damaged.

5. Tighten fitting (2) or nut (4) to the torque values shown.

Do not allow hose (5) to twist when tightening fittings.

6. Check for leaks. If oil leaks from a loose connection, do

not tighten fitting (2). Open the connection, replace

O-ring (1) and check for correct O-ring position before

tightening the connection.

Torque specifications

±10%

Width across flats (mm)

27

32

36

41,46

Fastening torque

N•m

95

140

180

210

(kgf•m) (9.5)

(14)

(18)

(21)

2

6 1

4

5

3

6

M104-07-033

Summary of Contents for ZAXIS 120-3 class

Page 1: ......

Page 3: ......

Page 5: ......

Page 49: ...SAFETY SIGNS Europe Asia Middle and Near East Model Only S 38 MEMO ...

Page 131: ...BREAK IN 2 MEMO ...

Page 191: ...TRANSPORTING 6 MEMO ...

Page 290: ...HYDRAULIC CIRCUIT AND ELECTRICAL CIRCUIT 8 HYDRAULIC CIRCUIT M1V1 08 001 ...

Page 292: ...8 ELECTRICAL DIAGRAM ...

Page 293: ...HYDRAULIC CIRCUIT AND ELECTRICAL CIRCUIT 8 MEMO ...

Page 295: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 MEMO ...

Page 351: ...SPECIFICATIONS 12 42 MEMO ...

Page 455: ...OPTIONAL ATTACHMENTS AND DEVICES 13 104 MEMO ...

Page 461: ...INDEX 14 MEMO ...