7-44

MAINTENANCE

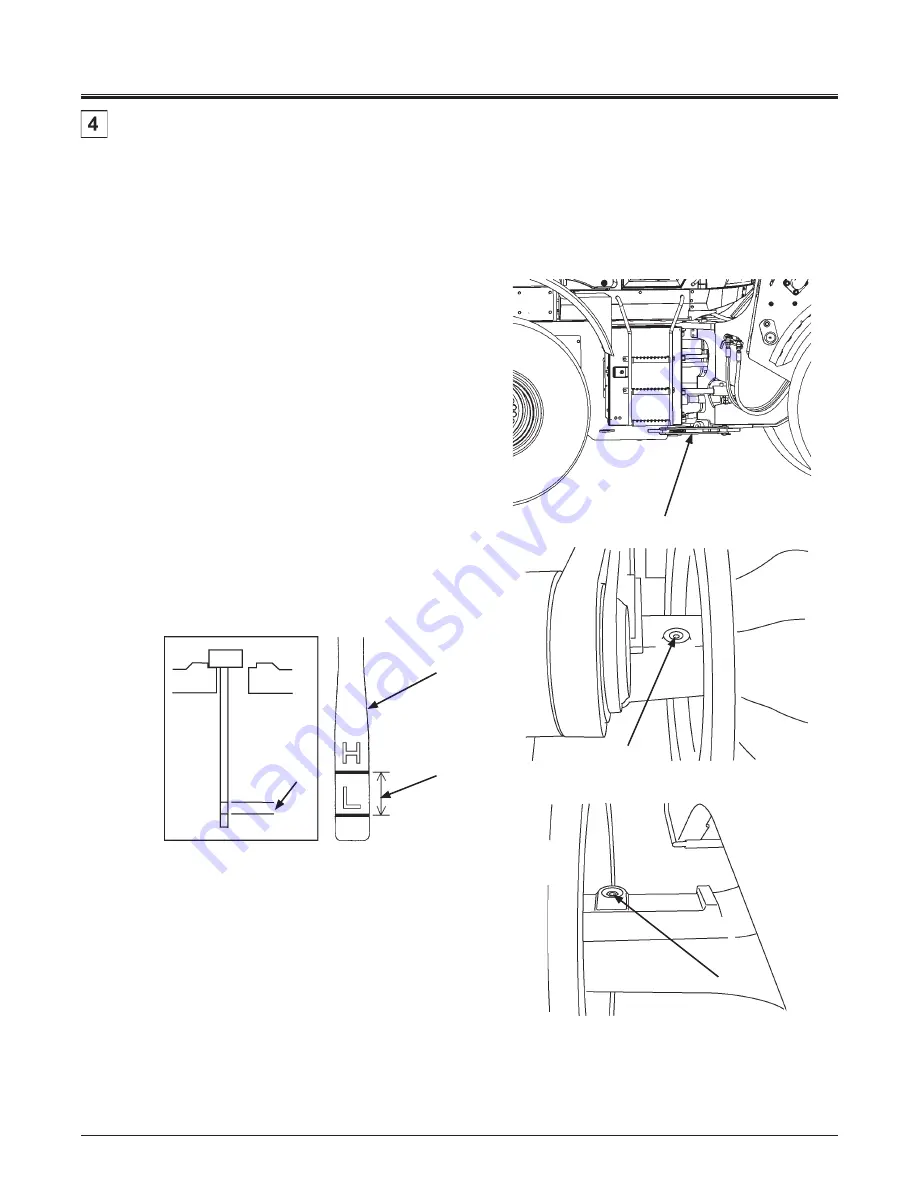

Change Axle Oil

--- every 2000 hours

d

WARNING: Take care about the following points.

Starting repair work immediately after operation

may cause burns. Wait for the oil to cool before

starting any maintenance work.

Lock the front and rear frames with the articulation

lock bar.

IMPORTANT: Do not use axle oils other than those listed

in the "Axle Oil".

Check Oil Level

1. Park the machine following the same procedures as

described on page 7-8 for preparation of inspection/

maintenance work.

2. Install articulation lock bar (1) to the front and rear of the

frame by following the procedures described on page

7-10.

3. Clean the vicinity of oil level plug (2).

4. Remove oil level plug (2). Clean the tip of dipstick (3)

connected to oil level plug (2) with a clean cloth.

5. Make the plug lower surface contact to the axle seat

face. Oil level must be between marks H and L (4) on the

dipstick (3).

If necessary, add oil.

2

2

M4GB-07-037

M4GB-07-038

Front Axle

Rear Axle

1

MNEK-01-019

M4GB-07-039

3

4

Specified

Oil Level

Summary of Contents for ZW 180-6

Page 4: ......

Page 10: ...CONTENTS MEMO ...

Page 52: ...S 40_70Z7B S 40 SAFETY LABELS 1 24 12 11 18 23 9 1 9 14 22 14 15 21 17 16 Battery Top 20 ...

Page 62: ...S 50 SAFETY LABELS MEMO ...

Page 204: ...2 2 BREAK IN MEMO ...

Page 238: ...4 20 MOVING THE MACHINE MEMO ...

Page 277: ...7 5 MAINTENANCE MEMO ...

Page 404: ...MAINTENANCE 7 132 MEMO ...

Page 408: ...9 4 MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS MEMO ...

Page 412: ...10 4 STORAGE MEMO ...

Page 418: ...12 2 SPECIFICATIONS MEMO ...

Page 426: ...14 6 INDEX MEMO ...