MAINTENANCE

7-84

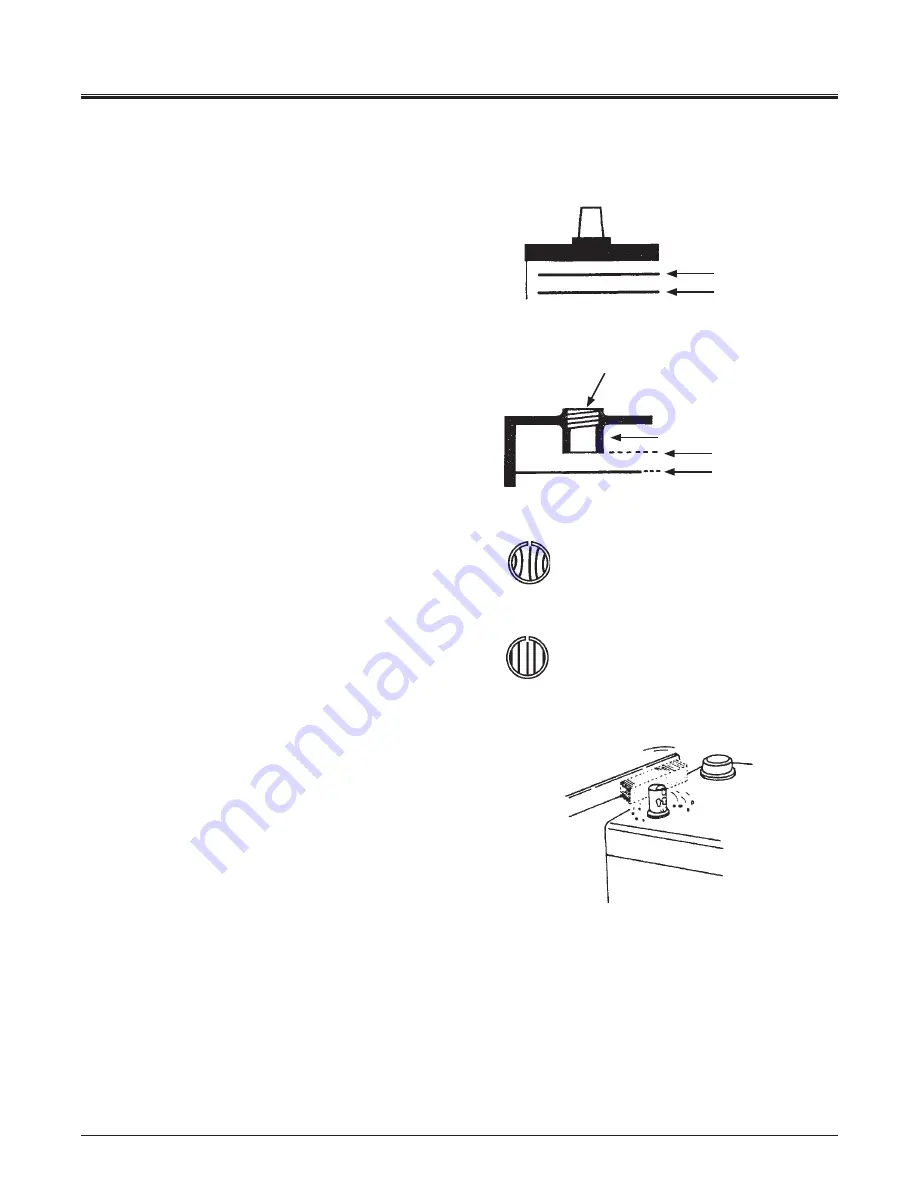

U.L (Upper Level)

L.L (Lower Level)

Upper Level

Lower Level

Filler Port

Sleeve

Separator Top

Correct

Lower

Since the electrolyte solution surface touches the bottom

end of the sleeve, the electrolyte solution surface is raised

due to surface tension so that the electrode ends are seen

curved.

When the electrolyte solution surface is lower than the

bottom end of the sleeve, the electrode ends are seen

straight.

M409-07-072

M146-07-109

M146-07-110

M146-07-111

M146-07-112

Electrolyte Level Check --- every 100 hours (monthly)

1. Check the electrolyte level at least once a month.

2. Park the machine on level ground and stop the engine.

3. Check the electrolyte level.

3.1 When checking the level from the battery side:

Clean around the level check lines with a wet towel.

Do not use a dry towel. Static electricity may be

developed, causing the battery gas to explode. Check

if the electrolyte level is between U.L (Upper Level) and

L.L (Lower Level).

If the electrolyte level is lower than the middle level

between the U.L and L.L, immediately refill with

distilled water or commercial battery fluid.

Be sure to refill with distilled water before recharging

(operating the machine).

After refilling, securely tighten the filler caps.

3.2 When impossible to check the level from the battery

side or no level check mark is indicated on the side:

After removing the filler plug from the top of the

battery. Check the electrolyte level by viewing through

the filler port. It is difficult to judge the accurate

electrolyte level in this case. When the electrolyte

level is at the U.L, the level is judged to be proper.

Referring to the illustrations at the right side, check

the level. When the electrolyte level is lower than the

bottom end of the sleeve, refill with distilled water or

commercial battery fluid up to the bottom end of the

sleeve.

After refilling, securely tighten the filler caps.

Be sure to refill with distilled water before recharging

(operating the machine).

3.3 When an indicator is available to check the level, follow

its check result.

4. Always keep the area around the battery terminals clean

to prevent battery discharge.

Check terminals for loose and/or rust. Coat terminals

with grease or petroleum jelly to prevent corrosion build

up.

Summary of Contents for ZW 180-6

Page 4: ......

Page 10: ...CONTENTS MEMO ...

Page 52: ...S 40_70Z7B S 40 SAFETY LABELS 1 24 12 11 18 23 9 1 9 14 22 14 15 21 17 16 Battery Top 20 ...

Page 62: ...S 50 SAFETY LABELS MEMO ...

Page 204: ...2 2 BREAK IN MEMO ...

Page 238: ...4 20 MOVING THE MACHINE MEMO ...

Page 277: ...7 5 MAINTENANCE MEMO ...

Page 404: ...MAINTENANCE 7 132 MEMO ...

Page 408: ...9 4 MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS MEMO ...

Page 412: ...10 4 STORAGE MEMO ...

Page 418: ...12 2 SPECIFICATIONS MEMO ...

Page 426: ...14 6 INDEX MEMO ...