MAINTENANCE

7-128

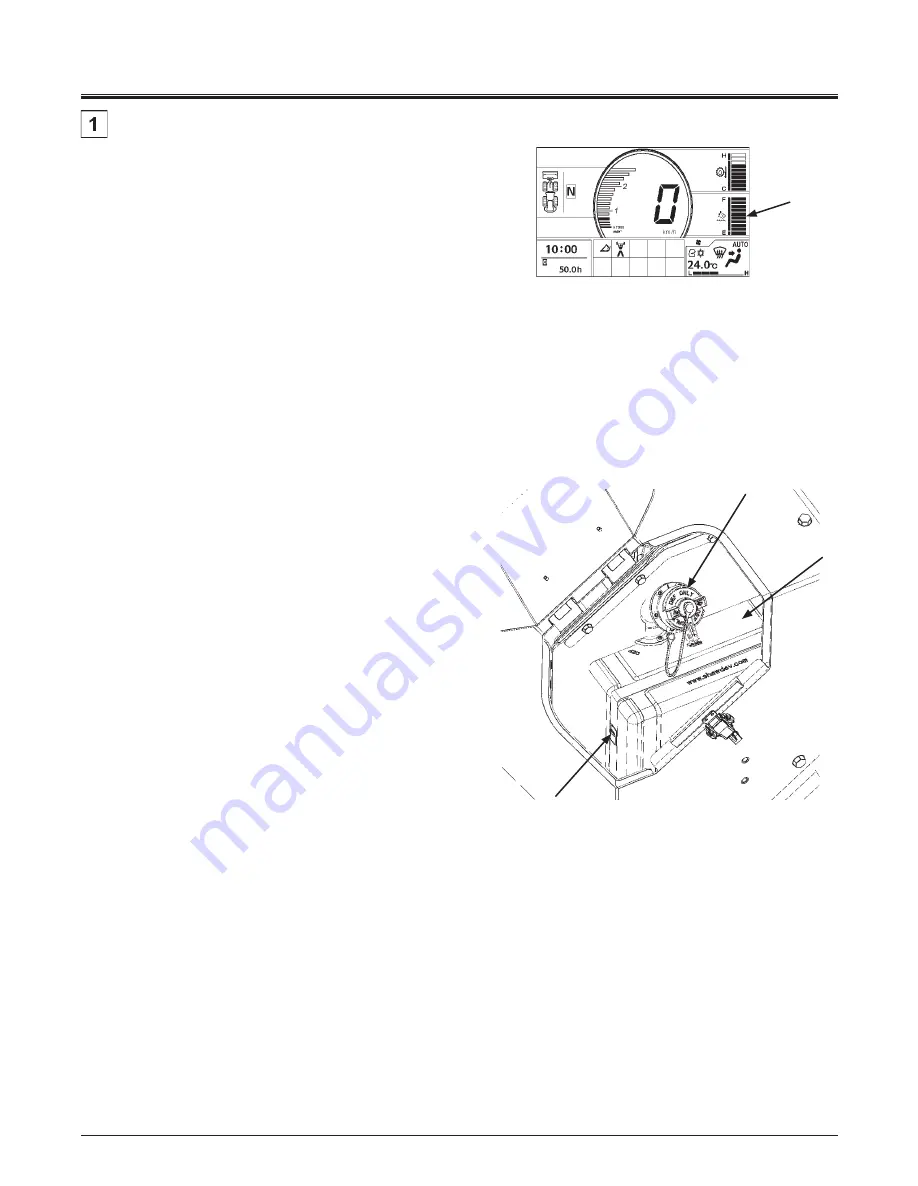

Check DEF/AdBlue®

--- every 10 hours (daily)

Park the machine on a level surface. Lower the bucket to the

ground. Check the DEF/AdBlue® level with DEF/AdBlue® gauge

(1).

If necessary, stop the engine and add DEF/AdBlue®.

Refill DEF/AdBlue®

d

CAUTION:

Refill DEF/AdBlue® which meets Japanese Industrial

Standards (JIS K2247), International Organization for

Standardization (ISO 22241) or Deutsche Industrie

Normen (DIN 70070) in DEF/AdBlue® tank (2). If

low density DEF/AdBlue® is refilled, alarm will be

generated, restricting machine operation. Do not

dilute DEF/AdBlue® with water.

Wear safety equipment such as safety glasses or

goggles, rubber gloves appropriate to the job. Wash

DEF/AdBlue® with clean water when it contacts on

the skin. If DEF/AdBlue® is accidentally splashed into

eyes, flush with water for 15 minutes or longer and

get emergency medical attention.

1. Park the machine according to the instruction on

"Preparations for Inspection and Maintenance" (7-8).

2. DEF/AdBlue® tank (2) is located in the cover at left rear of

the machine. Open the DEF/AdBlue® tank cover.

3. Clean dust and mud around the filler port of DEF/

AdBlue® tank with clean cloth.

4. Remove cap (3) from DEF/AdBlue® tank (2) and refill DEF/

AdBlue®. Be sure to stop refilling before the “FULL” line

(4).

IMPORTANT:

Take care not to allow dust and/or water to enter the

DEF/AdBlue® tank when refilling.

If DEF/AdBlue® is filled above the “FULL” line, the

system may be damaged during operation or tank

(2) may be broken when frozen.

MNEK-01-103EN

2

3

4

1

MNEK-07-033

Summary of Contents for ZW 180-6

Page 4: ......

Page 10: ...CONTENTS MEMO ...

Page 52: ...S 40_70Z7B S 40 SAFETY LABELS 1 24 12 11 18 23 9 1 9 14 22 14 15 21 17 16 Battery Top 20 ...

Page 62: ...S 50 SAFETY LABELS MEMO ...

Page 204: ...2 2 BREAK IN MEMO ...

Page 238: ...4 20 MOVING THE MACHINE MEMO ...

Page 277: ...7 5 MAINTENANCE MEMO ...

Page 404: ...MAINTENANCE 7 132 MEMO ...

Page 408: ...9 4 MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS MEMO ...

Page 412: ...10 4 STORAGE MEMO ...

Page 418: ...12 2 SPECIFICATIONS MEMO ...

Page 426: ...14 6 INDEX MEMO ...