MAINTENANCE

7-27

A. Greasing

d

WARNING: Apply the parking brake and the

articulation lock bar.

f

NOTE:

Until break-in operation is performed for more than

50 hours, lubricate the machine every day to get initial

operational concordance.

If excavation is made in mud, water or snow, lubricate the

machine after operation is complete.

Sufficiently add high quality grease through the grease

fittings. After removing contamination around the grease

fitting, add grease. After greasing, thoroughly remove the

old grease that was pushed-out from the seals.

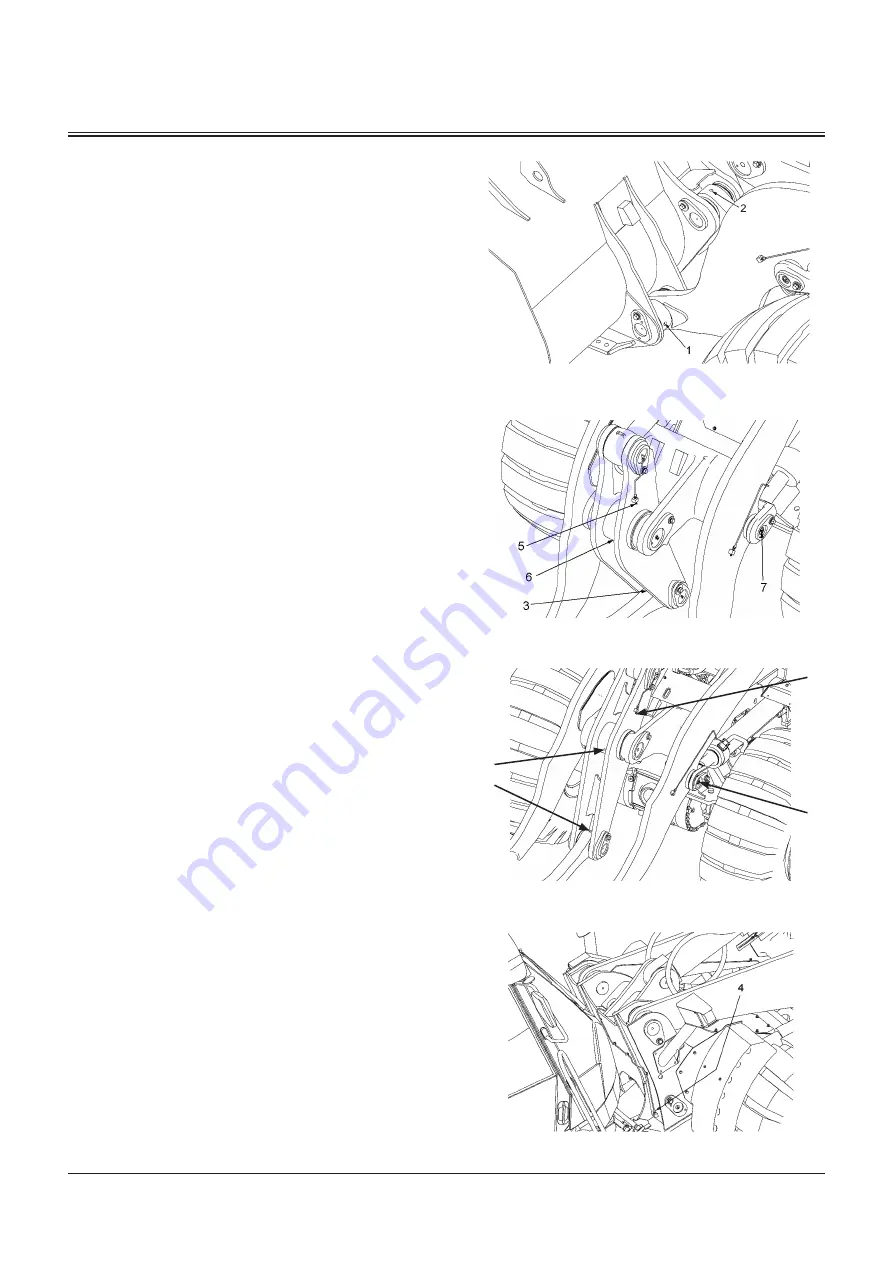

1. One point each to right and left bucket pins (1).

--- every 500 hours (250 hours at first time only)

2. One point each to bucket link pins (2 and 3).

--- every 500 hours (250 hours at first time only)

3. One point to bucket cylinder pin (4).

--- every 500 hours (250 hours at first time only)

One point to bucket cylinder rod pin (5).

--- every 500 hours (250 hours at first time only)

4. One point to bell crank pin (6).

--- every 500 hours (250 hours at first time only)

5. One point each to right and left lift arm cylinder rod pins

(7).

--- every 500 hours (250 hours at first time only)

90Z7-7-20-3

90Z7-7-20-1

90Z7-7-20-5

92Z7B-7-20-4

ZW310-6

ZW330-6

6

3

5

7

Summary of Contents for ZW 310-6

Page 4: ......

Page 10: ...CONTENTS MEMO ...

Page 14: ...INTENDED USE 2 MEMO ...

Page 57: ...SAFETY SIGNS S 43 ZW310 6 SS 3777 2 ...

Page 59: ...SAFETY SIGNS S 45 ZW330 6 92Z7B S 40EU ...

Page 246: ...BREAK IN 2 2 MEMO ...

Page 280: ...DRIVING MACHINE 4 20 MEMO ...

Page 460: ...MAINTENANCE 7 146 MEMO ...

Page 464: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 4 MEMO ...

Page 468: ...STORAGE 10 4 MEMO ...

Page 474: ...TROUBLESHOOTING 11 6 MEMO ...

Page 498: ...INDEX 14 6 MEMO ...

Page 502: ...CONFORMITY MEMO ...

Page 506: ......