MAINTENANCE

7-107

J. Tire

Check Air pressure

--- every 10 hours (daily)

Adjustment

--- as necessary

d

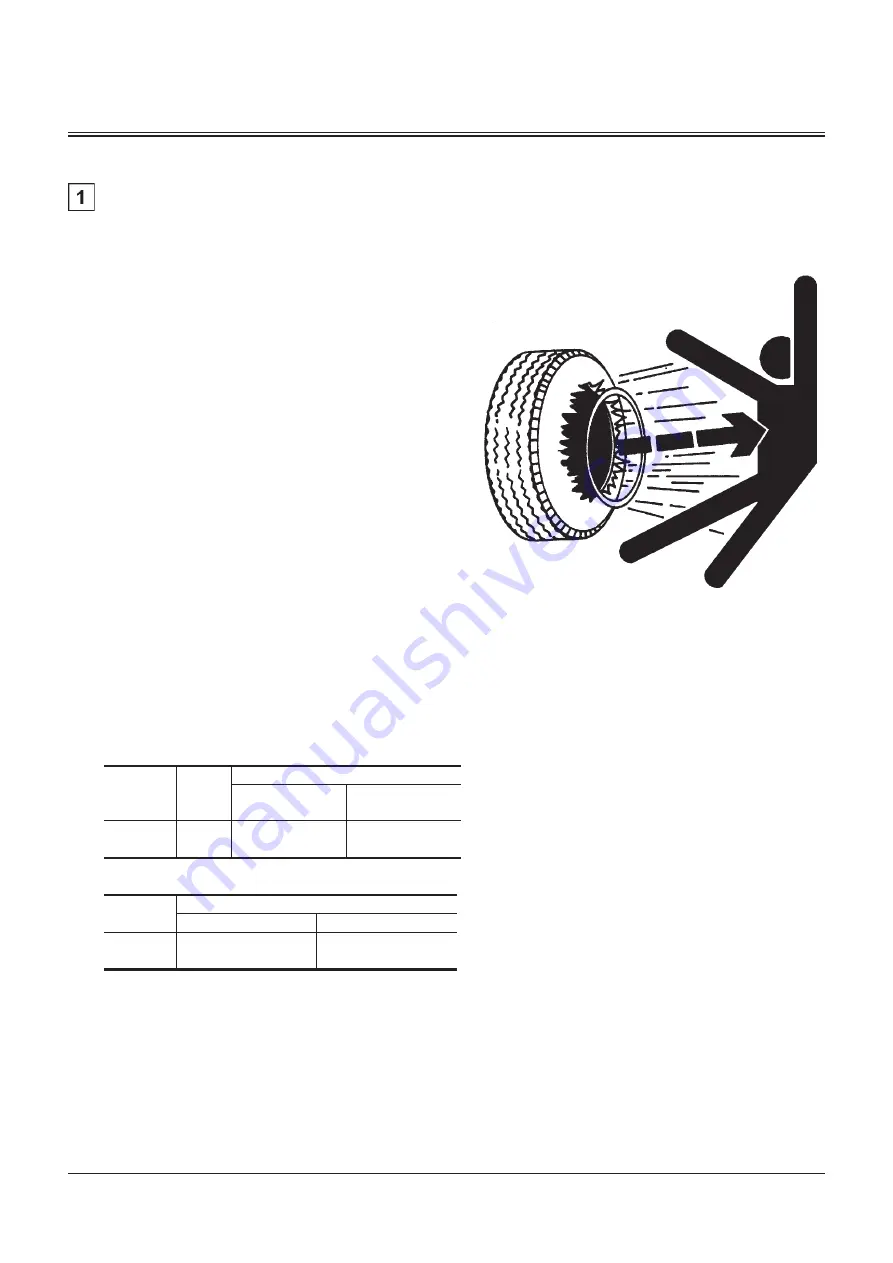

WARNING:

Secure the front and rear frames with the

articulation lock bar and pins.

When inflating tires, stand behind the tread and use

the self-attaching chuck.

Avoid welding near tires, which could potentially

cause the tires to explode.

Tires may explode if a tire is smoking such as if the

machine catches fire, the tires become abnormally

hot, or the air smells of rubber or tire bead burning.

IMPORTANT:

Always maintain the correct tire pressure.

Even if only one tread pattern has worn out, replace

the tire with a new one. Before operating the

machine, check the tires for any breaks, damage or

foreign matter.

When replacing one tire, use a new tire having the

same tread pattern and specification as the other

tires.

Check Air Pressure

1. Measure air pressure when the tires are cool before

operating the machine.

Bias

ply tire

(standard)

Pattern

Standard Air pressure

Front

Rear

26.5-25-

20PR

L-3~L-5

422~441 kPa

(4.3~4.5 kgf/cm

2

)

324~343 kPa

(3.3~3.5 kgf/cm

2

)

Radial tire

(option)

Standard Air pressure

Front

Rear

26.5R25

471~490 kPa

(4.8~5.0 kgf/cm

2

)

373~392 kPa

(3.8~4.0 kgf/cm

2

)

2. Check the external appearance of tires for any damage,

metal piece and extraneous material.

SA-249

Summary of Contents for ZW 310-6

Page 4: ......

Page 10: ...CONTENTS MEMO ...

Page 14: ...INTENDED USE 2 MEMO ...

Page 57: ...SAFETY SIGNS S 43 ZW310 6 SS 3777 2 ...

Page 59: ...SAFETY SIGNS S 45 ZW330 6 92Z7B S 40EU ...

Page 246: ...BREAK IN 2 2 MEMO ...

Page 280: ...DRIVING MACHINE 4 20 MEMO ...

Page 460: ...MAINTENANCE 7 146 MEMO ...

Page 464: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 4 MEMO ...

Page 468: ...STORAGE 10 4 MEMO ...

Page 474: ...TROUBLESHOOTING 11 6 MEMO ...

Page 498: ...INDEX 14 6 MEMO ...

Page 502: ...CONFORMITY MEMO ...

Page 506: ......