MAINTENANCE

7-128

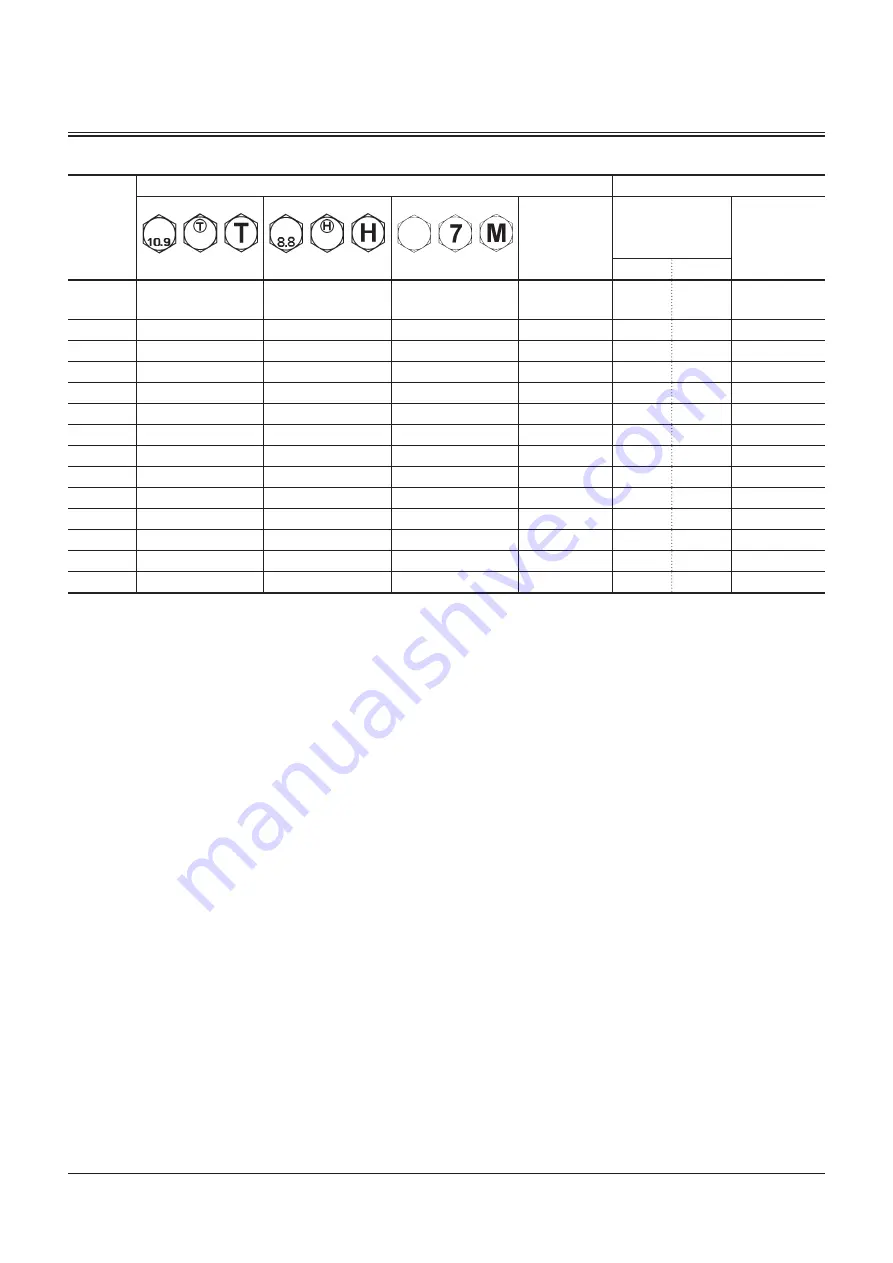

Tightening Torque Chart

Bolt Dia.

mm

Hexagon Wrench

Socket Bolt

Wrench Size

mm

Socket Bolt

Wrench Size

mm

N·m (kgf·m)

N·m (kgf·m)

N·m (kgf·m)

N·m

(kgf·m)

6

3.3 to 4.2

(0.3 to 0.4)

10

5

8

30

(3.0)

20

(2.0)

10

(1.0)

13

20

(2.0)

6

10

65

(6.5)

50

(5.0)

20

(2.0)

17

50

(5.0)

8

12

110

(11)

90

(9)

35

(3.5)

19

90

(9)

10

14

180

(18)

140

(14)

55

(5.5)

22

140

(14)

12

16

270

(27)

210

(21)

80

(8.0)

24

210

(21)

14

18

400

(40)

300

(30)

120

(12)

27

300

(30)

14

20

550

(55)

400

(40)

170

(17)

30

400

(40)

17

22

750

(75)

550

(55)

220

(22)

32

24

950

(95)

700

(70)

280

(28)

36

27

1400

(140)

1050

(105)

400

(40)

41

30

1950

(195)

1450

(145)

550

(55)

46

33

2600

(260)

1950

(195)

750

(75)

50

36

3200

(320)

2450

(245)

950

(95)

55

d

CAUTION: If fixing bolts for counterweight are

loosened, consult your nearest authorized dealer.

IMPORTANT:

Apply lubricant (e. g. white zinc B solved into spindle

oil) to bolts and nuts to stabilize their friction

coefficient.

Remove soil, dust, and/or dirt from the nut and bolt

thread surfaces before tightening.

Tighten nuts and bolts to specifications. If tightened

with excessively low or high torque, missing or

breakage of nuts and/or bolts may result.

Summary of Contents for ZW 310-6

Page 4: ......

Page 10: ...CONTENTS MEMO ...

Page 14: ...INTENDED USE 2 MEMO ...

Page 57: ...SAFETY SIGNS S 43 ZW310 6 SS 3777 2 ...

Page 59: ...SAFETY SIGNS S 45 ZW330 6 92Z7B S 40EU ...

Page 246: ...BREAK IN 2 2 MEMO ...

Page 280: ...DRIVING MACHINE 4 20 MEMO ...

Page 460: ...MAINTENANCE 7 146 MEMO ...

Page 464: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 4 MEMO ...

Page 468: ...STORAGE 10 4 MEMO ...

Page 474: ...TROUBLESHOOTING 11 6 MEMO ...

Page 498: ...INDEX 14 6 MEMO ...

Page 502: ...CONFORMITY MEMO ...

Page 506: ......