MNEC-01-036

MNEC-07-001

1

2

8

7

6

95Z7-1-85-1

10

MOVING THE MACHINE

4-16

Stop

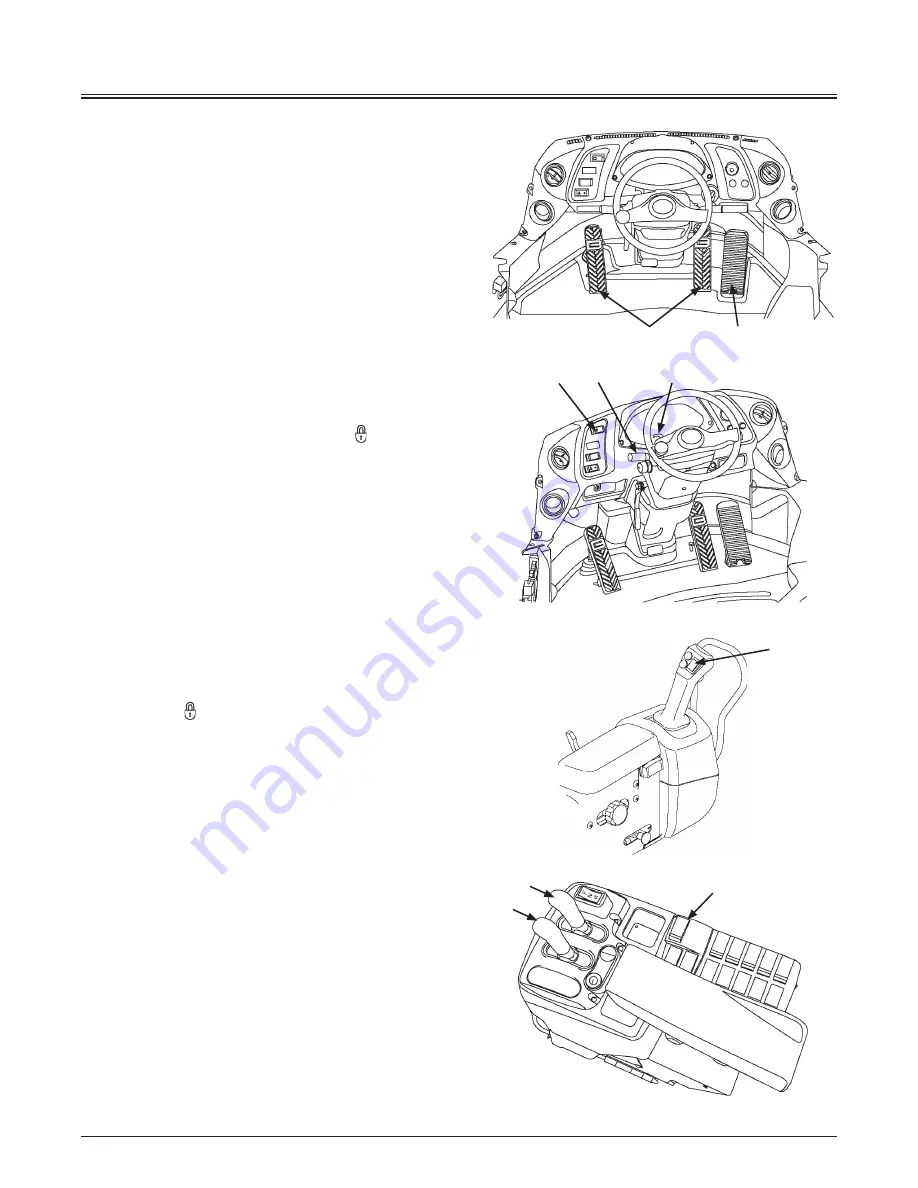

1. Avoid sudden deceleration. Smoothly reduce operating

speed.

Release accelerator pedal (1) and step on brake pedal (2)

to stop the machine.

2. Return forward/reverse lever (3) or forward/reverse

switch (10) (option) to neutral (N).

Place neutral lever lock (4) to the lock ( ) position.

3. Press the ON position of parking brake switch (5).

4. Level the bucket with the surface of the ground and

lower the bucket to the ground by operating bucket

control lever (6) and lift arm control lever (7).

5. Press lock ( ) side of control lever lock switch (8).

IMPORTANT: This machine is equipped with a

turbocharged engine. Therefore if the engine is

stopped without first cooling down at low RPM’s,

the lubricant on the turbocharger bearing and seal

surfaces may be dissipated due to the intense heat

present inside turbocharger, possibly damaging the

turbocharger.

6. Run the engine at slow idle speed for 5 minutes to cool

the engine.

f

NOTE: Do not idle for excessively long periods.

Observe local and federal engine idling regulations.

MNEC-01-037

5

3

4

Summary of Contents for ZW 370-6

Page 4: ...MEMO ...

Page 10: ...CONTENTS MEMO ...

Page 12: ...2 MACHINE NUMBERS Aftertreatment Device SCR TYPE MFG NO DOC TYPE MFG NO 95Z7B SCR4 95Z7B SCR4 ...

Page 53: ...SAFETY LABELS S 41 95Z7B S 40 ...

Page 148: ...1 84 OPERATOR S STATION MEMO ...

Page 218: ...OPERATOR S STATION 1 154 MEMO ...

Page 220: ...2 2 BREAK IN MEMO ...

Page 236: ...3 16 OPERATING THE ENGINE MEMO ...

Page 284: ...OPERATING THE MACHINE 5 28 MEMO ...

Page 426: ...MAINTENANCE 7 132 MEMO ...

Page 430: ...9 4 MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS MEMO ...

Page 434: ...10 4 STORAGE MEMO ...

Page 440: ...11 6 TROUBLESHOOTING MEMO ...

Page 442: ...12 2 SPECIFICATIONS MEMO ...

Page 450: ...14 8 INDEX MEMO ...