OPERATING THE MACHINE

5-2

f

NOTE:

1.

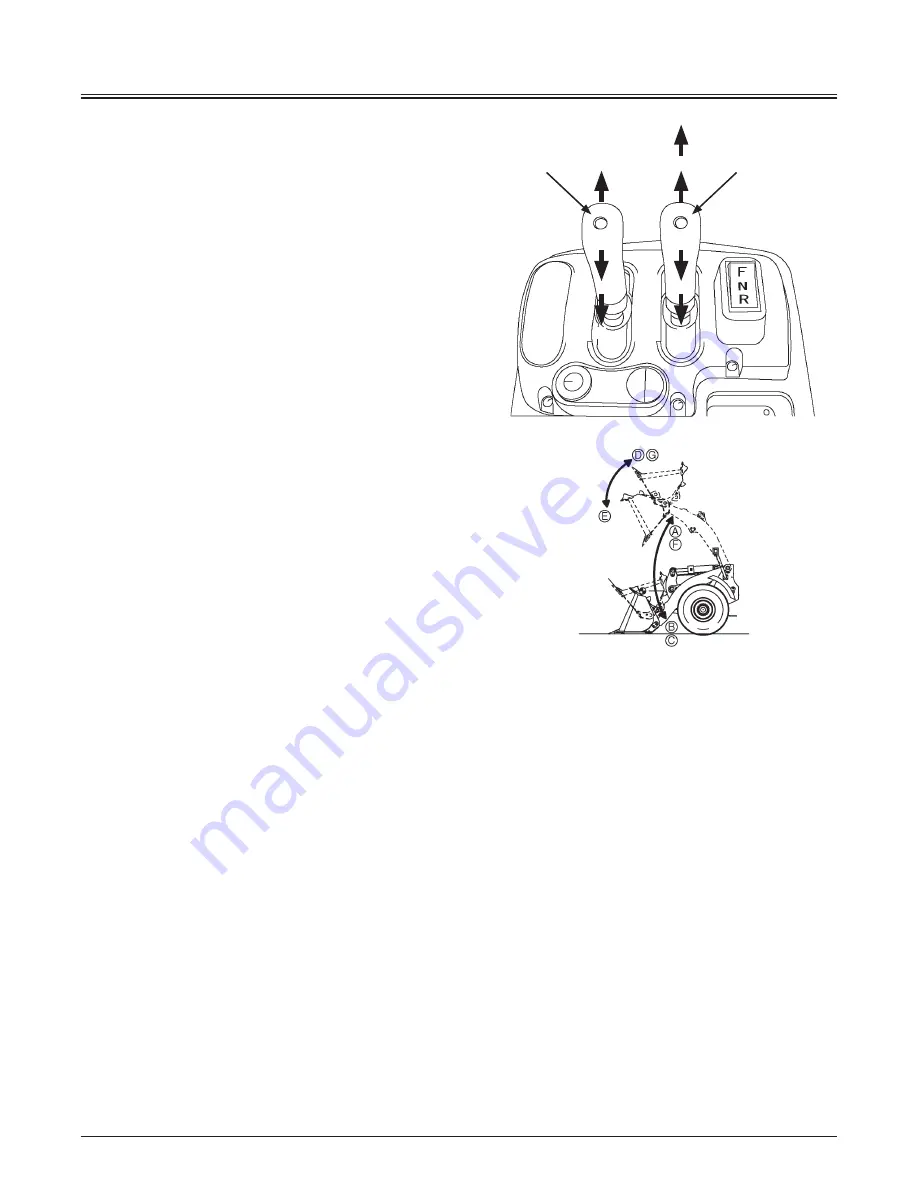

When applying lift arm control lever (1) in the "Raise"

position (A), the lever is moved (F) until the lift arm reaches

the position preset by the lift arm kickout. When the lift

arm moves the preset position, lift arm control lever (1)

automatically moves to the Neutral (N) position.

2.

When applying bucket control lever (2) in the "Tilt"

position (D) after bucket dump operation, the lever is moved

(G) until the bucket reaches the position preset by the bucket

auto leveler. When the bucket reaches the preset position,

bucket control lever (2) automatically moves to the Neutral

(N) position.

3.

When pushing down lift arm control lever (1) to the

"Float" position (C), the lift arm moves to the position preset

by lift arm auto-leveler system and is held in that position.

When the lift arm moves to the preset position, lift arm

control lever (1) automatically moves to the "Neutral" (N)

position. (Machine is equipped with the lift arm auto-leveler

system)

f

NOTE: When operating the machine in Float (C) position,

first hold the lift arm at the float position; then further tilt

the lever to the Float position, and lower the lift arm on the

ground.

M4GB-01-073

2

1

MNEC-03-003

C

B

E

N

N

A

F

G

D

Summary of Contents for ZW 370-6

Page 4: ...MEMO ...

Page 10: ...CONTENTS MEMO ...

Page 12: ...2 MACHINE NUMBERS Aftertreatment Device SCR TYPE MFG NO DOC TYPE MFG NO 95Z7B SCR4 95Z7B SCR4 ...

Page 53: ...SAFETY LABELS S 41 95Z7B S 40 ...

Page 148: ...1 84 OPERATOR S STATION MEMO ...

Page 218: ...OPERATOR S STATION 1 154 MEMO ...

Page 220: ...2 2 BREAK IN MEMO ...

Page 236: ...3 16 OPERATING THE ENGINE MEMO ...

Page 284: ...OPERATING THE MACHINE 5 28 MEMO ...

Page 426: ...MAINTENANCE 7 132 MEMO ...

Page 430: ...9 4 MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS MEMO ...

Page 434: ...10 4 STORAGE MEMO ...

Page 440: ...11 6 TROUBLESHOOTING MEMO ...

Page 442: ...12 2 SPECIFICATIONS MEMO ...

Page 450: ...14 8 INDEX MEMO ...