7-12

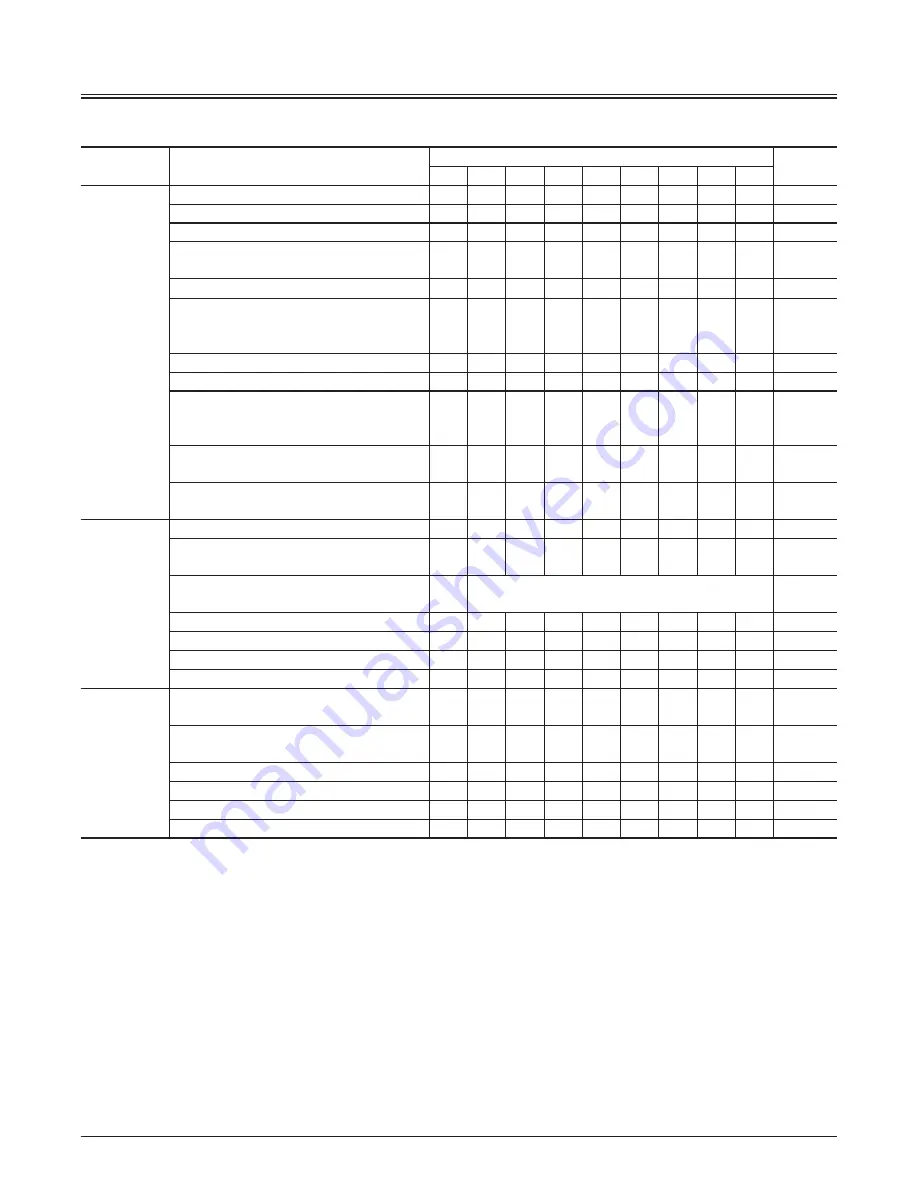

MAINTENANCE

: First time replacement or cleaning only

Section

Item for check

Operating hours

Page

10

50

100 250 500 1000 2000 4000 4500

Loading

system

Check Hydraulic Oil Level

7-40

Check Bucket Teeth and Cutting Edge

7-106

Check Hoses and Lines for Leaks

7-51

Check Hoses and Lines for Cracks, Bends,

Etc.

7-51

Greasing

*1

*2

7-18

Check Ride Control Accumulator

Function, Gas Leakage, Looseness, and

Damage (Option)

7-50

Replace Hydraulic Tank Oil Return Filter

7-47

Replace Air Breather Element

7-48

Check Pilot Circuit Accumulator

Function, Gas Leakage, Looseness, and

Damage

7-49

Check Gas pressure in Ride Control

Accumulator (Option)

7-50

Change Hydraulic Oil and Clean Suction

Filter

*4

7-41,

7-43

Chassis

Check Outer and Inner Rear View Mirrors

7-117

Check ROPS Cab Mounts, Resin Cab

Roof, and Roof Mounting Bolts

7-113

Check and Replace Seat Belt and Lower

Tether

Every 3 years

7-113

Clean Engine Room and Hood

7-118

Check Steps, Grab Handles and Handrails

7-117

Check Windshield Washer Fluid Level

7-113

Greasing (Center Pin)

7-20

Electrical

system

Check All Monitor Functions and

Instrument Operation

7-83

Check Horn and Back Up Alarm

Operation

7-85

Check Work Lights

7-84

Check Electrical Harnesses and Fuses

7-86

Check Battery Electrolyte Level

7-81

Check Electrolyte Specific Gravity

7-82

f

NOTE:

*1 Add grease daily during first 50 hours of operation. In

case the machine is engaged in

excavation in mud, water or snow, add grease after each work shift.

*2 After 50 hours of operation, carry out next greasing at

the first 250 hours of operation.

Then, carry out greasing every 500 hours of operation afterwards. Shorten greasing

intervals when the machine is operated under severe conditions or when the machine is

continuously operated for a long period of time.

*4 Hydraulic oil changing interval differs according to the

kind of hydraulic oil used.

Summary of Contents for ZW 370-6

Page 4: ...MEMO ...

Page 10: ...CONTENTS MEMO ...

Page 12: ...2 MACHINE NUMBERS Aftertreatment Device SCR TYPE MFG NO DOC TYPE MFG NO 95Z7B SCR4 95Z7B SCR4 ...

Page 53: ...SAFETY LABELS S 41 95Z7B S 40 ...

Page 148: ...1 84 OPERATOR S STATION MEMO ...

Page 218: ...OPERATOR S STATION 1 154 MEMO ...

Page 220: ...2 2 BREAK IN MEMO ...

Page 236: ...3 16 OPERATING THE ENGINE MEMO ...

Page 284: ...OPERATING THE MACHINE 5 28 MEMO ...

Page 426: ...MAINTENANCE 7 132 MEMO ...

Page 430: ...9 4 MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS MEMO ...

Page 434: ...10 4 STORAGE MEMO ...

Page 440: ...11 6 TROUBLESHOOTING MEMO ...

Page 442: ...12 2 SPECIFICATIONS MEMO ...

Page 450: ...14 8 INDEX MEMO ...