7-18

MAINTENANCE

A. Greasing

d

CAUTION: Apply the parking brake and the

articulation stopper (lock bar) (Refer to page 7-8).

f

NOTE:

Until break-in is performed for more than 50 hours,

lubricate the machine every day to get initial lubrication.

In case excavation is made in mud, water or snow,

lubricate the machine after operation is complete.

Add high quality grease through the grease fittings. After

removing contamination around the grease fitting, add

grease. After greasing, thoroughly remove the old grease

that was pushed-out from the seals and grease at the

grease zerk nipple.

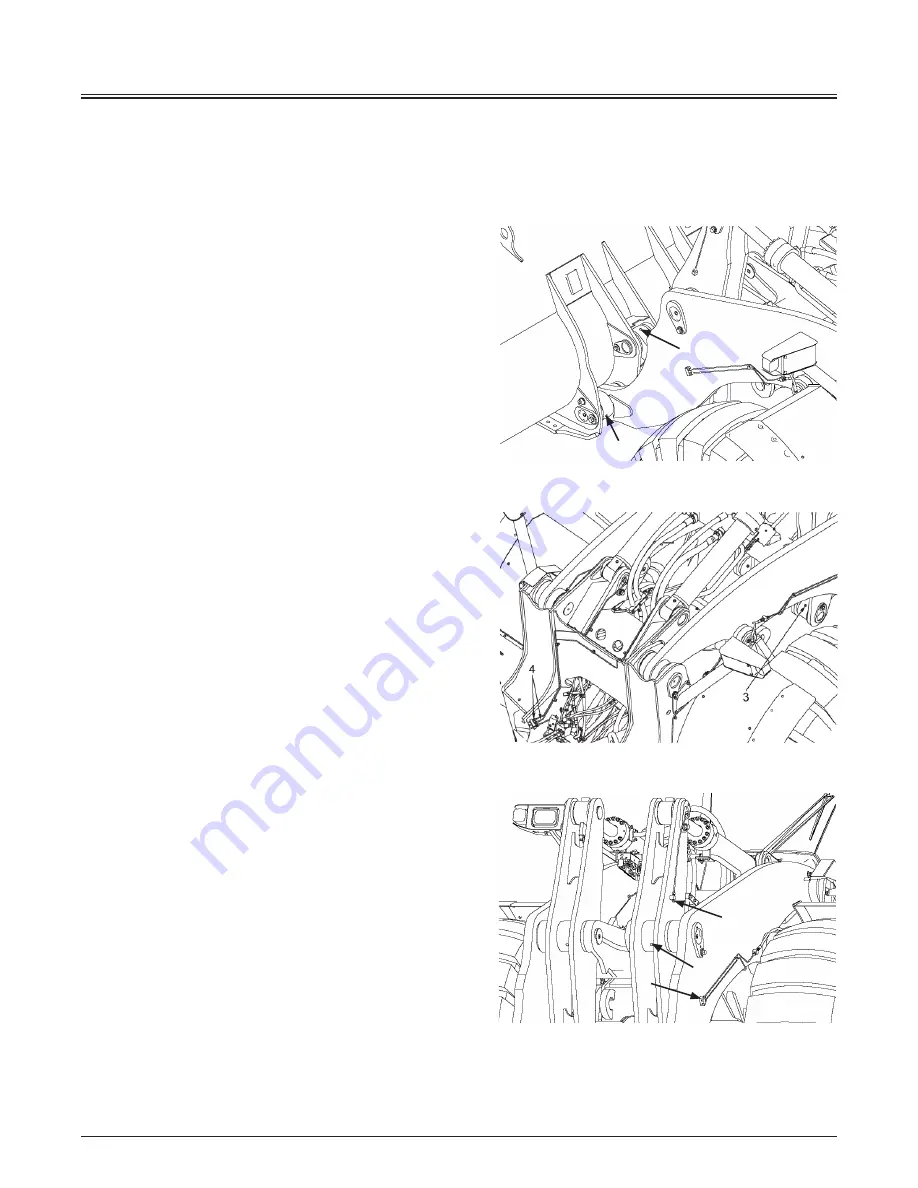

1. One point each to right and left bucket pins (1).

--- every 500 hours (250 hours at first time only)

2. One point each to bucket link pins (2 and 3).

--- every 500 hours (250 hours at first time only)

3. One point to bucket cylinder pin (4).

--- every 500 hours (250 hours at first time only)

4. One point each to right and left bucket cylinder rod pins

(5).

--- every 500 hours (250 hours at first time only)

5. One point each to right and left bell crank pins (6).

--- every 500 hours (250 hours at first time only)

6. One point each to right and left lift arm cylinder rod

pins (7).

--- every 500 hours (250 hours at first time only)

95Z7B-7-19-1

95Z7-7-20-2

95Z7B-7-19-3

2

1

7

6

5

Summary of Contents for ZW 370-6

Page 4: ...MEMO ...

Page 10: ...CONTENTS MEMO ...

Page 12: ...2 MACHINE NUMBERS Aftertreatment Device SCR TYPE MFG NO DOC TYPE MFG NO 95Z7B SCR4 95Z7B SCR4 ...

Page 53: ...SAFETY LABELS S 41 95Z7B S 40 ...

Page 148: ...1 84 OPERATOR S STATION MEMO ...

Page 218: ...OPERATOR S STATION 1 154 MEMO ...

Page 220: ...2 2 BREAK IN MEMO ...

Page 236: ...3 16 OPERATING THE ENGINE MEMO ...

Page 284: ...OPERATING THE MACHINE 5 28 MEMO ...

Page 426: ...MAINTENANCE 7 132 MEMO ...

Page 430: ...9 4 MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS MEMO ...

Page 434: ...10 4 STORAGE MEMO ...

Page 440: ...11 6 TROUBLESHOOTING MEMO ...

Page 442: ...12 2 SPECIFICATIONS MEMO ...

Page 450: ...14 8 INDEX MEMO ...