7-45

MAINTENANCE

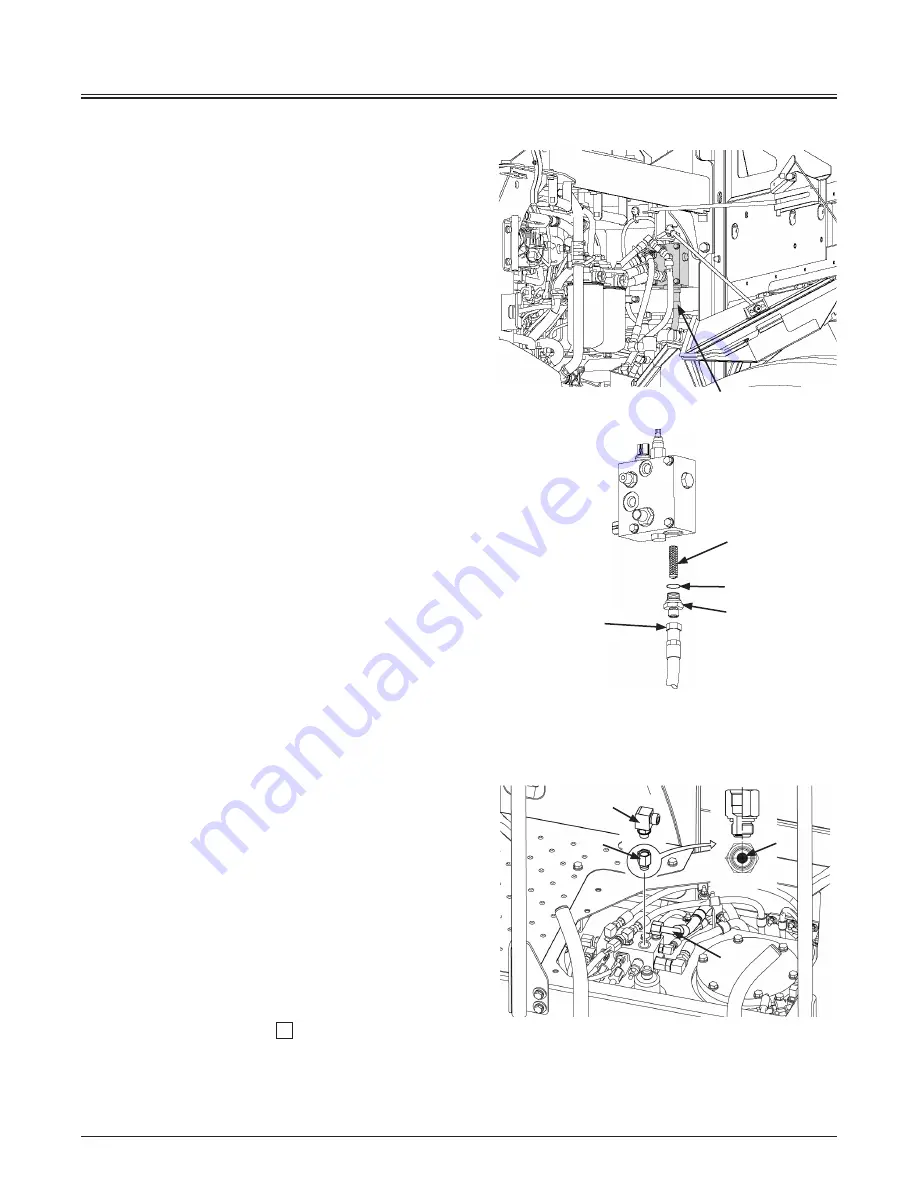

[ Line Filter in Brake Circuit ]

7. Disconnect hose (7).

Remove adapter (8) and remove filter (9) inside of valve

using a screwdriver (-).

8. Place a suitable container under the filter.

9. Clean filter (9) by applying air or cleaning solution from

the oil flow outlet side.

10. Install the cleaned filter with O-ring (11).

f

NOTE: Filter elements (3) and (9) are identical.

[ Line Filter in Brake Circuit ]

11. Disconnect hose (12).

Remove adapter (13) and fitting (14).

12. Clean filter (15) in fitting (14) applying air or cleaning

solution from the oil flow outlet side.

13. Install the cleaned fitting (14), adapter (13) and hose

(12).

14. After cleaning the filter, bleed air from the hydraulic

pump and check the oil level in the hydraulic oil tank.

(Refer to the descriptions for "Bleed air from the

hydraulic system" in item

2

.)

If the machine is operated without bleeding the air

mixed in the hydraulic circuit, damage to the hydraulic

pump may result.

95Z7B-7-46-02

95Z7B-7-46-4

95Z7B-7-46-1

7

13

14

15

12

7

9

11

8

Summary of Contents for ZW 370-6

Page 4: ...MEMO ...

Page 10: ...CONTENTS MEMO ...

Page 12: ...2 MACHINE NUMBERS Aftertreatment Device SCR TYPE MFG NO DOC TYPE MFG NO 95Z7B SCR4 95Z7B SCR4 ...

Page 53: ...SAFETY LABELS S 41 95Z7B S 40 ...

Page 148: ...1 84 OPERATOR S STATION MEMO ...

Page 218: ...OPERATOR S STATION 1 154 MEMO ...

Page 220: ...2 2 BREAK IN MEMO ...

Page 236: ...3 16 OPERATING THE ENGINE MEMO ...

Page 284: ...OPERATING THE MACHINE 5 28 MEMO ...

Page 426: ...MAINTENANCE 7 132 MEMO ...

Page 430: ...9 4 MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS MEMO ...

Page 434: ...10 4 STORAGE MEMO ...

Page 440: ...11 6 TROUBLESHOOTING MEMO ...

Page 442: ...12 2 SPECIFICATIONS MEMO ...

Page 450: ...14 8 INDEX MEMO ...