7-47

MAINTENANCE

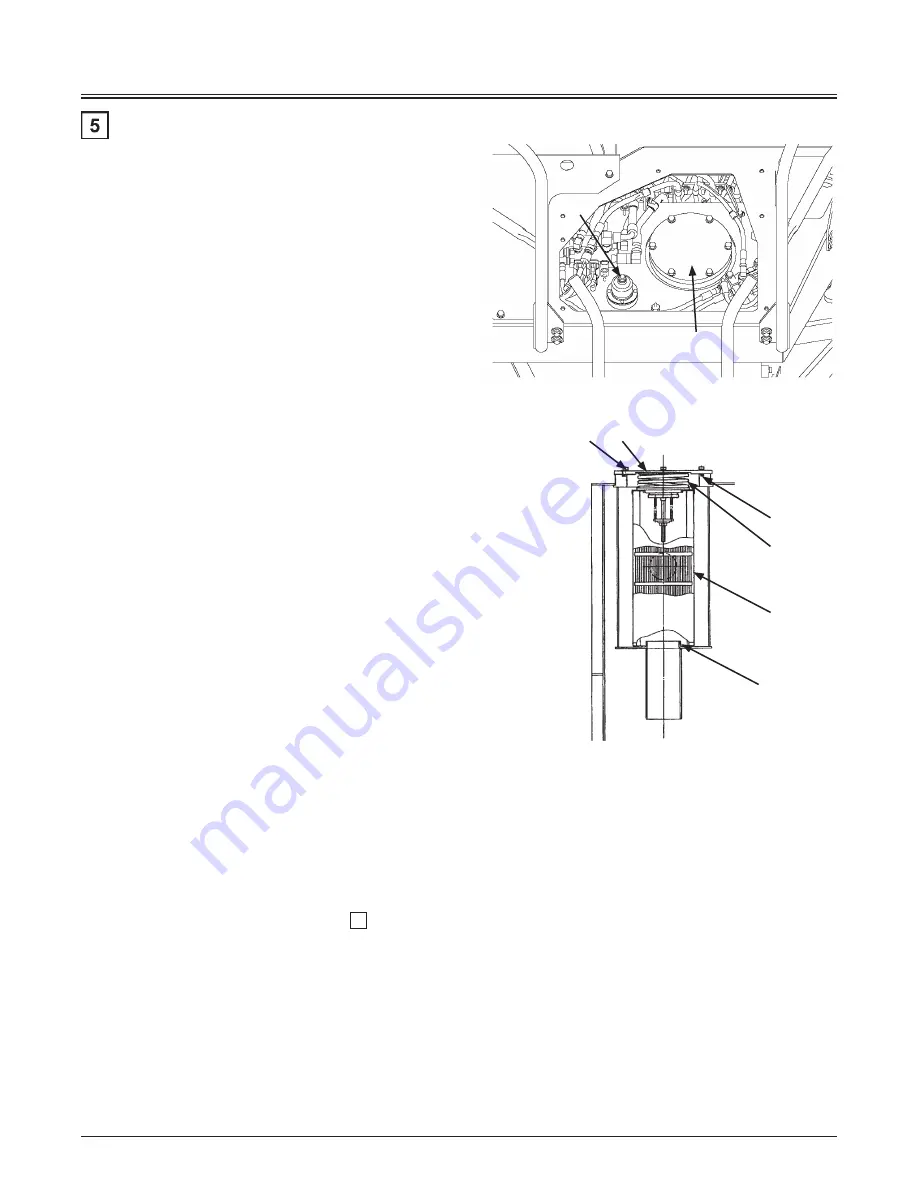

Replace Hydraulic Oil Return Filter

--- every 1000 hours

d

WARNING: Hydraulic oil becomes hot during

operation. Severe burns may result if skin comes in

contact with hot hydraulic oil. Wait for the oil to cool

before starting any maintenance work.

Especially when removing the filter, be careful that

the remaining oil in the filter does not spill.

Replacement Procedures

1. Park the machine following the same procedures as

described on page 7-6 for preparation of inspection/

maintenance work.

2. Install articulation stopper (lock bar) to the front

and rear of the chassis by following the procedures

described on page 7-8.

3. Clean the vicinity around cover plate (1).

4. Get a container and workshop towels to hold the spilled

oil and the element.

Relieve the air pressure from the hydraulic oil tank by

pressing air bleed valve (6).

5. Loosen bolts (2) (6 used) to remove cover (1) and O-ring

(3).

When removing cover (1), slowly remove the cover

while pressing the cover downward so that spring

(4) does not fly off. Slowly permit cover to rise, then

carefully remove.

6. Remove spring (4), and element (5).

7. Replace element (5) and O-ring (3) with new ones.

Install new element and new O-ring in the hydraulic oil

tank.

Before installing element (5), make sure that rubber (7)

is present.

8. Install cover (1) with bolts (2) (6 used).

m

: 50 N·m (5.0 kgf·m, 37 lbf·ft)

9. After replacing the return filter element, bleed air

from the hydraulic pump and check the oil level in the

hydraulic oil tank. [Refer to the descriptions for “Bleed

air from the hydraulic system” in item

2

.]

If the machine is operated without bleeding the air

mixed in the hydraulic circuit, damage to the hydraulic

pump may result.

f

NOTE: Replace the element at the regular intervals to

maintain clean hydraulic oil and extend the service life of the

hydraulic components.

3

4

5

7

1

2

M4GB-07-052

95Z7B-7-42-2

1

6

Summary of Contents for ZW 370-6

Page 4: ...MEMO ...

Page 10: ...CONTENTS MEMO ...

Page 12: ...2 MACHINE NUMBERS Aftertreatment Device SCR TYPE MFG NO DOC TYPE MFG NO 95Z7B SCR4 95Z7B SCR4 ...

Page 53: ...SAFETY LABELS S 41 95Z7B S 40 ...

Page 148: ...1 84 OPERATOR S STATION MEMO ...

Page 218: ...OPERATOR S STATION 1 154 MEMO ...

Page 220: ...2 2 BREAK IN MEMO ...

Page 236: ...3 16 OPERATING THE ENGINE MEMO ...

Page 284: ...OPERATING THE MACHINE 5 28 MEMO ...

Page 426: ...MAINTENANCE 7 132 MEMO ...

Page 430: ...9 4 MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS MEMO ...

Page 434: ...10 4 STORAGE MEMO ...

Page 440: ...11 6 TROUBLESHOOTING MEMO ...

Page 442: ...12 2 SPECIFICATIONS MEMO ...

Page 450: ...14 8 INDEX MEMO ...