S-24

SAFETY

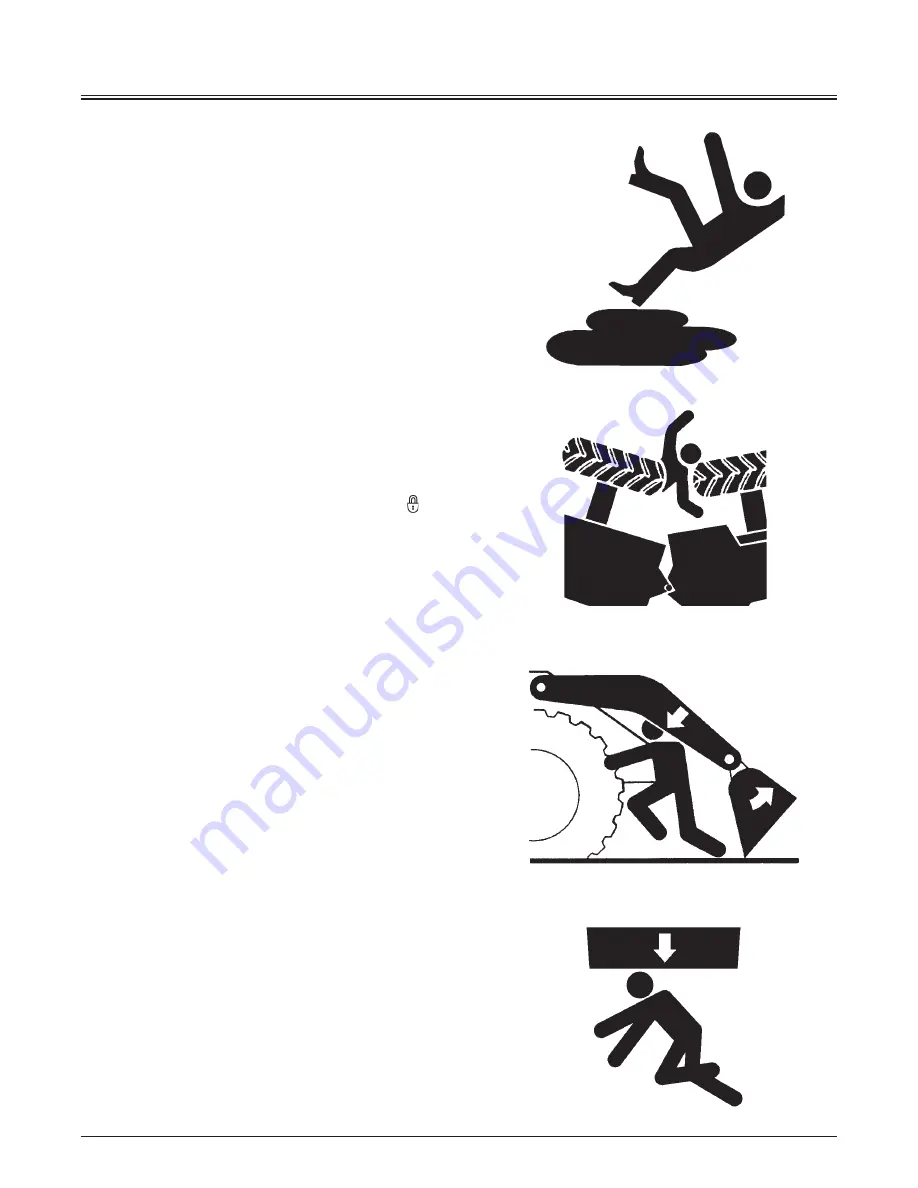

Practice Safe Maintenance

To avoid accidents:

Understand service procedures before starting work.

Keep the work area clean and dry.

Do not spray water or steam inside cab.

Never lubricate or service the machine while it is moving.

Keep hands, feet and clothing away from power-driven

parts.

Before servicing the machine:

1. Park the machine on a level surface.

2. Lower the bucket to the ground.

3. Run the engine at low idle speed without load for 3

minutes.

4. Turn the key switch to OFF to stop engine. Wait for some

seconds and turn the key switch to ON again.

5. Relieve the pressure in the hydraulic system by moving

the control levers several times.

6. Turn the control lever lock switch to the LOCK ( )

position.

7. Turn the key switch to OFF, and remove the key from the

key switch.

8. Attach a “Do Not Operate” tag on the control lever.

9. Connect the front and rear chassis with articulation

stopper.

10. Allow the engine to cool.

Refer to page 7-6 "Preparations for Inspection and

Maintenance".

If a maintenance procedure must be performed with the

engine running, do not leave machine unattended.

Never work under a machine raised by the lift arm.

Inspect certain parts periodically and repair or replace as

necessary. Refer to the section discussing that part in the

“MAINTENANCE” chapter of this manual.

Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

When cleaning parts, always use nonflammable

detergent oil. Never use highly flammable oil such as fuel

oil and gasoline to clean parts or surfaces.

Disconnect battery ground cable (-) before making

adjustments to electrical systems or before performing

welding on the machine.

SA-028

SA-527

SA-312

SA-134

Summary of Contents for ZW 370-6

Page 4: ...MEMO ...

Page 10: ...CONTENTS MEMO ...

Page 12: ...2 MACHINE NUMBERS Aftertreatment Device SCR TYPE MFG NO DOC TYPE MFG NO 95Z7B SCR4 95Z7B SCR4 ...

Page 53: ...SAFETY LABELS S 41 95Z7B S 40 ...

Page 148: ...1 84 OPERATOR S STATION MEMO ...

Page 218: ...OPERATOR S STATION 1 154 MEMO ...

Page 220: ...2 2 BREAK IN MEMO ...

Page 236: ...3 16 OPERATING THE ENGINE MEMO ...

Page 284: ...OPERATING THE MACHINE 5 28 MEMO ...

Page 426: ...MAINTENANCE 7 132 MEMO ...

Page 430: ...9 4 MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS MEMO ...

Page 434: ...10 4 STORAGE MEMO ...

Page 440: ...11 6 TROUBLESHOOTING MEMO ...

Page 442: ...12 2 SPECIFICATIONS MEMO ...

Page 450: ...14 8 INDEX MEMO ...