MAINTENANCE

7-108

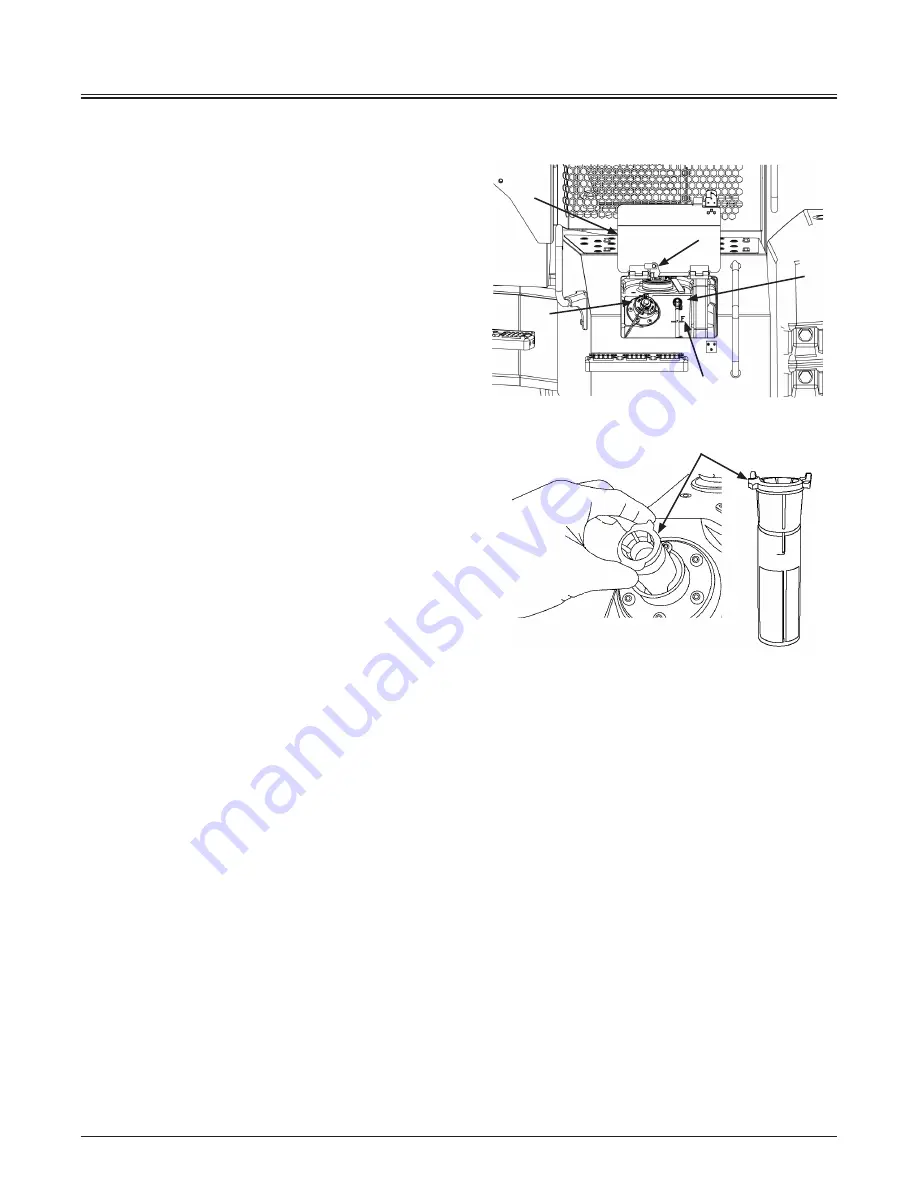

5 . Install cap (5) after refilling DEF. Turn stopper plate (4)

to the original position. Close the tank cover (3).

IMPORTANT:

Do not get on top of DEF tank (2) or sensors and

piping on the tank. Failure to do so may damage

the machine.

White deposition may be observed when DEF

is dried naturally; it is normal. Wash out DEF

deposition with soft water. Never use a high

pressure washer.

f

NOTE:

Wipe spilled DEF and wash spilled area with plenty of

water.

Flow sound may be heard from the tank after the

engine stops. It is the sound of returning DEF from

piping to the tank, not the malfunction.

DEF will freeze under low temperature, deteriorate

(ammonification) under high temperature. Store the

DEF in -10 to 30°C (14 to 86°F) environment.

Use dedicated container (purchased container) to store

or carry DEF. Or use polyethylene resin tank or stainless

tank.

Clean DEF Strainer

Check strainer (7) installed at the inlet of DEF tank, and

clean it as needed.

d

CAUTION: Use rubber gloves and goggles or

safety glasses for protection during operation.

Wash DEF with clean water when it contacts on the

skin. If splashed in eyes, flush with water for 10 to

15 minutes. Get medical attention immediately.

IMPORTANT: Take care not to allow dirt and/or water

to enter the DEF tank while checking or cleaning

strainer (7).

1. Take out strainer (7) from the DEF inlet port.

IMPORTANT:

Use compressed air at the lower pressure than 0.2

MPa (30 PSI).

Completely dry strainer before reinstalling to

avoid water from entering.

2. Clean strainer (7) by applying compressed air or

flushing with tap water.

3. Install strainer (7) at the DEF inlet port.

f

NOTE: Consult your nearest authorized dealer if DEF

spills out while filling even after cleaning strainer (7).

95Z7B-7-105-4

3

2

5

4

6

95Z7B-7-126-3

7

Summary of Contents for ZW 370-6

Page 4: ...MEMO ...

Page 10: ...CONTENTS MEMO ...

Page 12: ...2 MACHINE NUMBERS Aftertreatment Device SCR TYPE MFG NO DOC TYPE MFG NO 95Z7B SCR4 95Z7B SCR4 ...

Page 53: ...SAFETY LABELS S 41 95Z7B S 40 ...

Page 148: ...1 84 OPERATOR S STATION MEMO ...

Page 218: ...OPERATOR S STATION 1 154 MEMO ...

Page 220: ...2 2 BREAK IN MEMO ...

Page 236: ...3 16 OPERATING THE ENGINE MEMO ...

Page 284: ...OPERATING THE MACHINE 5 28 MEMO ...

Page 426: ...MAINTENANCE 7 132 MEMO ...

Page 430: ...9 4 MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS MEMO ...

Page 434: ...10 4 STORAGE MEMO ...

Page 440: ...11 6 TROUBLESHOOTING MEMO ...

Page 442: ...12 2 SPECIFICATIONS MEMO ...

Page 450: ...14 8 INDEX MEMO ...