MAINTENANCE

7-112

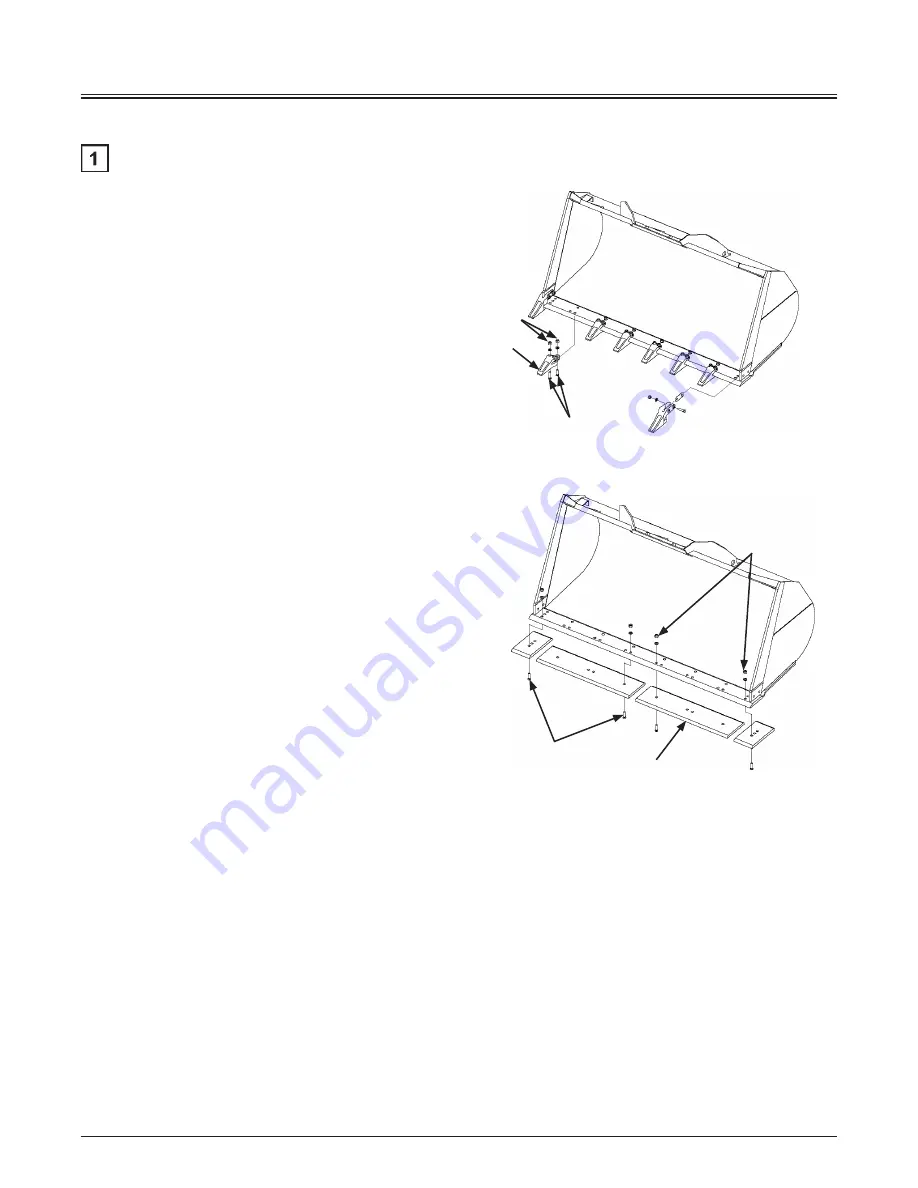

N. Miscellaneous

Check Bucket Teeth and Cutting Edge

--- every 10 hours (daily)

Check bucket teeth for wear and looseness.

Replace

d

WARNING: Guard against injury from flying pieces

of metal. Wear goggles or safety glasses, hard hat and

face shield.

1. Raise the bucket to an appropriate height with the

bucket bottom parallel to the ground. Insert hard wood

support blocks under the bucket to support it.

Stop the engine.

2. Loosen bolts (1) and nuts (2). Remove bucket teeth (3)

or cutting edge (4).

3. Install new teeth (3) or cutting edge (4). If the reverse

side of a cutting edge is not worn much, use it again

with the unused edge forward. If both sides are worn

out, replace it with a new one.

4. Tighten nuts (2).

m

Bucket teeth:

7/8-9UNC bolt: 834 N·m (85 kgf·m, 615 lbf·ft)

1-8UNC bolt:

1314 N·m (134 kgf·m, 970 lbf·ft)

m

Cutting edge:

7/8-9UNC bolt: 834 N·m (85 kgf·m, 615 lbf·ft)

1-8UNC bolt:

1314 N·m (134 kgf·m, 970 lbf·ft)

5. Retighten mounting nuts (2) after a few hours of

operation.

1

2

3

1

4

2

95Z7B-7-130-1

95Z7B-7-130-2

Summary of Contents for ZW 370-6

Page 4: ...MEMO ...

Page 10: ...CONTENTS MEMO ...

Page 12: ...2 MACHINE NUMBERS Aftertreatment Device SCR TYPE MFG NO DOC TYPE MFG NO 95Z7B SCR4 95Z7B SCR4 ...

Page 53: ...SAFETY LABELS S 41 95Z7B S 40 ...

Page 148: ...1 84 OPERATOR S STATION MEMO ...

Page 218: ...OPERATOR S STATION 1 154 MEMO ...

Page 220: ...2 2 BREAK IN MEMO ...

Page 236: ...3 16 OPERATING THE ENGINE MEMO ...

Page 284: ...OPERATING THE MACHINE 5 28 MEMO ...

Page 426: ...MAINTENANCE 7 132 MEMO ...

Page 430: ...9 4 MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS MEMO ...

Page 434: ...10 4 STORAGE MEMO ...

Page 440: ...11 6 TROUBLESHOOTING MEMO ...

Page 442: ...12 2 SPECIFICATIONS MEMO ...

Page 450: ...14 8 INDEX MEMO ...