MAINTENANCE

7-61

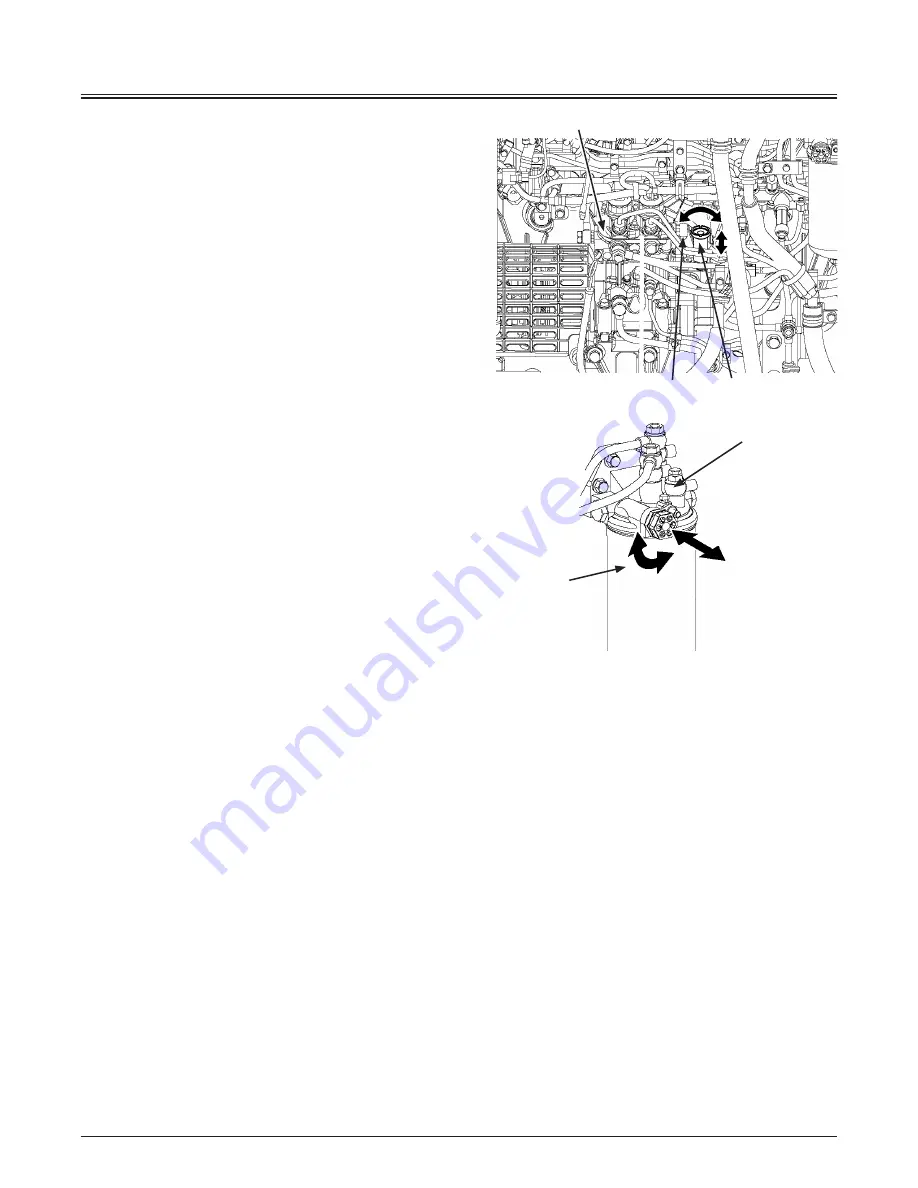

3. Keep the key switch at ON position while operating

priming pump (9) of supply pump (7) until fuel with

no air bubbles comes out from air bleed plug (6) at

the outlet port of fuel priming solenoid pump (5).

Tighten air bleed plug (6).

4. Bleed air of supply pump (7) and fuel main filter (10)

in the same manner respectively. Verify that fuel with

no air bubbles come out from air bleed plugs (8)(11).

5. Keep the key switch at ON position for at least 30

seconds after priming main fuel filter (10).

6. Once the engine is started, slowly increase the

engine speed while air is purged from the fuel line.

7. Check the fuel supply system for fuel leaks.

IMPORTANT: Even if air is not thoroughly bled of fuel

priming solenoid pump (5) at step 3, do not hold

the key switch in the ON position for more than 5

minutes. In this case, first return the key switch to

the OFF position. Then, after waiting for more than

30 seconds, turn the key switch ON again. Failure to

do so may cause damage to fuel priming solenoid

pump (5) and/or discharging the batteries.

If Air Mixed After Common Rail

d

WARNING: INJECTION HAZARD

Fuel under high pressure

High pressure common rail, high pressure lines fuel

lines and high pressure fuel injection lines contain

high pressure fuel.

High pressure fuel injection into skin can cause

injury or death.

Keep hands away from injection lines while turning

engine with starter or while running engine.

In case air mixed in the fuel system due to lack of

fuel and the engine is difficult to start, release air by

following the procedure given below.

1. Bleed air until supply pump (7) inlet sufficiently

according to the above-mentioned procedures.

2. Operate starter motor for long cranking within 20

seconds. If engine fails to start, return key switch to

OFF. Wait more than about 60 seconds, and then try

again.

11

10

115Z7B-7-61-2

8

7

9

95Z7B-7-61-1

Summary of Contents for ZW 550-6

Page 4: ......

Page 10: ...CONTENTS SPECIFICATIONS 12 1 Specifications 12 1 Intended Use 12 1 INDEX 14 1 ...

Page 12: ...MACHINE NUMBERS 2 Aftertreatment Device SCR TYPE MFG NO DOC TYPE MFG NO 95Z7B SCR4 95Z7B SCR4 ...

Page 54: ...SAFETY LABELS S 42 2 25 7 4 1 26 1 8 9 5 6 11 12 10 24 115Z7B S 42US ...

Page 148: ...OPERATOR S STATION 1 84 MEMO ...

Page 208: ...OPERATOR S STATION 1 144 MEMO ...

Page 210: ...BREAK IN 2 2 MEMO ...

Page 226: ...OPERATING THE ENGINE 3 16 MEMO ...

Page 274: ...OPERATING THE MACHINE 5 28 MEMO ...

Page 354: ...MAINTENANCE 7 70 MEMO ...

Page 418: ...9 4 MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS MEMO ...

Page 422: ...10 4 STORAGE MEMO ...

Page 428: ...11 6 TROUBLESHOOTING MEMO ...

Page 430: ...SPECIFICATIONS 12 2 MEMO ...

Page 438: ...INDEX 14 8 ZW550 6 US MEMO ...