GENERAL / Tightening

W1-2-1

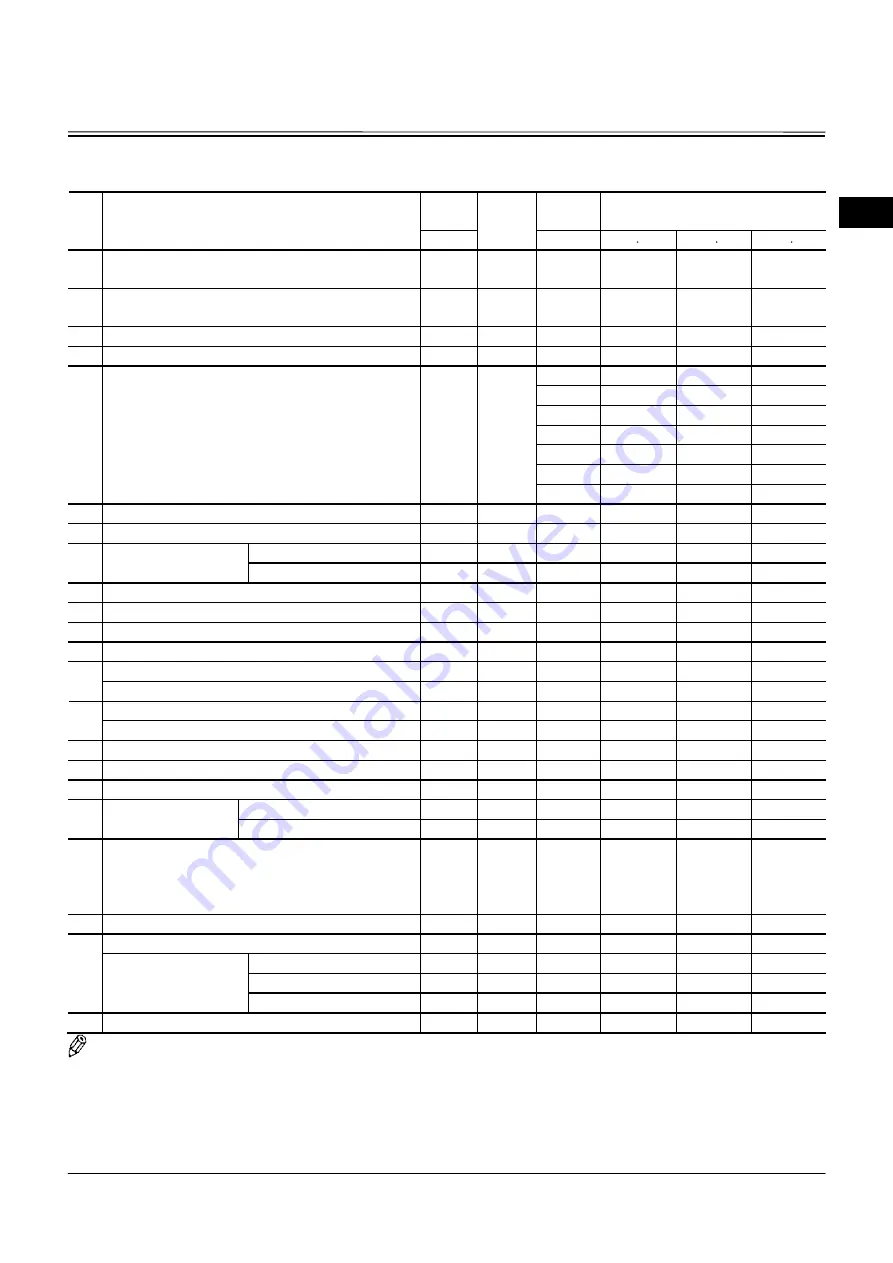

TIGHTENING TORQUE SPECIFICATIONS

Bolt Dia

Wrench

Size

Torque

No.

Descriptions

mm

Qty

mm

N m

(kgf m)

(lbf ft)

1

Engine cushion rubber mounting bolt

14

16

2

2

22

24

180

270

(18.4)

(27.5)

(133)

(200)

2

Engine bracket mounting bolt

10

12

8

8

17

19

50

90

(5.1)

(9.2)

(37)

(66)

3

Hydraulic oil tank mounting bolt

16

4

24

270

(27.5)

(200)

4

Fuel tank mounting bolt

16

4

24

210

(21.5)

(155)

17

2.5

(2)

(15)

19

29.5

(3)

(22)

22

39

(4)

(29)

27

93

(9.5)

(69)

32

137

(14)

(101)

36

175

(18)

(129)

5

ORS fittings for hydraulic hoses and piping

41

205

(21)

(151)

6

Pump mounting bolt

18

2

27

300

(30.5)

(220)

7

Control valve mounting bolt

14

3

22

180

(18.4)

(133)

ZX70-3, 70LC-3, 70LCN-3

12

4

19

90

(9.2)

(66)

8

Control valve bracket

mounting bolt

ZX75US-3, 85US-3

14

4

22

140

(14.3)

(103)

9

Swing device mounting bolt

16

10

24

210

(21.5)

(155)

10 Swing motor mounting bolt

14

8

12

175

(18)

(129)

11 Battery mounting nut

10

4

17

20

(2.0)

(15.0)

12 Cab mounting nut

16

4

24

210

(21.5)

(155)

Swing bearing mounting bolt to upperstructure

16

24

24

210

(21.5)

(155)

13

Swing bearing mounting bolt to undercarriage

16

24

24

270

(27.5)

(200)

Travel device mounting bolt

16

20

24

300

(31)

(220)

14

Travel reduction device cover mounting bolt

14

8

22

140

(14.3)

(103)

15 Sprocket mounting bolt

16

24

24

270

(27.5)

(200)

16 Upper roller mounting bolt

14

2

22

140

(14.3)

(103)

17 Lower roller mounting bolt

14

40

22

245

(25)

(180)

ZX70-3, 70LCN-3

14

304

22

245

(25)

(180)

18 Track shoe bolt

ZX70LC-3, 75US-3, 85US-3

14

320

22

245

(25)

(180)

19 Cover mounting bolt

6

18

10

12

10

13

17

19

10

20

50

90

(1)

(2)

(5.1)

(9.2)

(7.4)

(15)

(37)

(66)

20 Flexible master coupling of low pressure piping

8

4

13

10.3 to 12.4 (1.05 to 1.26) (7.6 to 9.1)

Coupling of low pressure piping

4

9.5

4.4

(0.45)

(3.3)

Suction hose

2

11

10

(1.0)

(7.4)

In-take air duct

1

9.5

7.3

(0.74)

(5.4)

21 T-bolt clamp of low

pressure piping

Radiator hose

1

9.5

7.3

(0.74)

(5.4)

22 Side-cutter mounting bolt

20

6

30

540

(55)

(400)

NOTE: 1. Apply lubricant (e.g. white zinc B dis-

solved into spindle oil) to bolts and nuts

to reduce friction coefficient of them.

2. Make sure bolt and nut threads are

clean before installing.