BSW

FAN-COIL HIGH PRESSURE

22

06.18 Ref. 207483 Rev.102

TURNING THE COIL

CAUTION

The fan wheels may reach the speed of 1,000 rpm. Do not insert objects into the

electric fan and certainly not hands. The motor becomes hot during operation;

wait for it to cool before touching it. During the heating mode of operation the

exchanger and the connecting pipes may become very hot (80°C). Wait for the

exchanger to cool before touching it or protect hands with suitable gloves. The

heat exchange water coils are suitable for working up to a maximum pressure

of 8 bar.

To turn the coil, proceed as follows:

1. Disconnect the terminal board (6) from the side of the unit.

2. Remove the condensate collecting tray (2).

3. Remove the coil fixing screws (5).

4. Take out the coil (3), being careful not to be cut by the fins and not to dama-

ge them.

5. Remove the knockouts (1) on the opposite side of the unit (using a screwdri-

ver) to allow the coil connections to pass through.

6. Position the coil, turning it without tipping it upside down, so that the fittings

are in line with the holes left by the knockouts.

7. Fix the coil using the previously removed screws (5).

8. Shift the terminal board (fixing it to the side opposite the water fittings) and

the motor cables, fixing them with their clamps. Ensure that the cables pass

through the hole in the side of the unit, protecting them with the relative grom-

met. If it proves easier to carry out this operation by separating the wires from

the terminal board, mark the positions of the wires to avoid making mistakes

when reconnecting.

9. Reconnect the wires to the relative terminal board (6), taking care that they

are correctly positioned.

10. Replace the condensate collecting tray (2).

CLEANING AND MAINTENANCE

CAUTION

Before carrying out any cleaning or maintenance work, disconnect the

unit from the mains electricity supply!

ROUTINE MAINTENANCE

The user is duty bound to have all maintenance operations carried out by trai-

ned and qualified personnel only. If the unit has to be dismantled, protect hands

with work gloves.

Monthly checks:

- Ensure that the fan impellers are clean. If they are dirty, clean them by suction

so as not to damage them.

- Check the whole of the electrical part and in particular that the electrical con-

nections are tight.

Yearly checks:

- Check the whole of the electrical part and in particular that the electrical con-

nections are tight.

- Check the tightness of all the bolts, nuts and whatever else may be loosened

by the constant vibrations of the unit.

- Check the motor for dust, dirt or other impurities. Periodically check that the

motor works without unusual vibrations or noise and that the fan inlet is not ob-

structed, which could otherwise leading to overheating of the windings.

- Check the fans for dirt or any foreign matter.

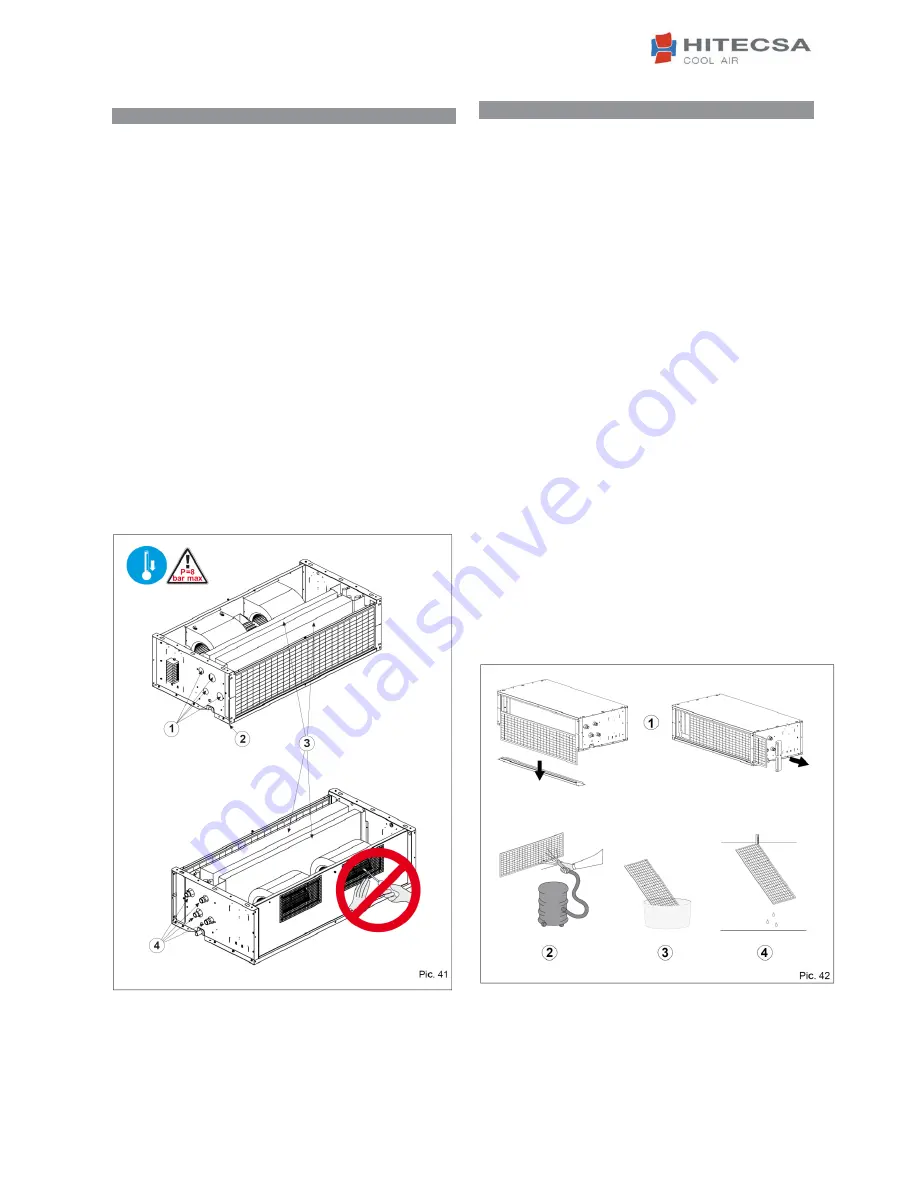

CLEANING THE AIR FILTER

The unit is fitted with an air filter on the fan inlet. During normal operation the

filter holds back impurities in the air.

The filter should be cleaned periodically to keep its filtering properties and the

airflow to the fan unchanged.

It is advisable to clean the filter at least once a month, proceeding as follows.

1. Take out the filter.

2. Place the filter on a flat, dry surface and remove the accumulated dust with

a vacuum cleaner.

3. Wash the filter with water and detergent (no solvents).

4. Leave the filter to dry in a ventilated place in the sun.

5. Replace the filter when it is perfectly dry.

Please clean the air filter every working season of the unit or more fre-

quently considering the unit activity.

NOTE: the filter may also be taken out from the side or from the top.

INS

T

AL

L

A

T

IO

N, O

P

E

R

A

T

IO

N

AN

D

MAIN

T

E

NAN

C

E

MANUAL

Summary of Contents for BSW 1

Page 2: ...BSW FAN COIL HIGH PRESSURE 2 06 18 Ref 207483 Rev 102 ...

Page 19: ...BSW FAN COIL HIGH PRESSURE 06 18 Ref 207483 Rev 102 19 WIRING DIAGRAM MOD 1 3 ...

Page 20: ...BSW FAN COIL HIGH PRESSURE 20 06 18 Ref 207483 Rev 102 WIRING DIAGRAM MOD 4 5 ...

Page 21: ...BSW FAN COIL HIGH PRESSURE 06 18 Ref 207483 Rev 102 21 WIRING DIAGRAM MOD 6 7 ...

Page 24: ...BSW FAN COIL HIGH PRESSURE 24 06 18 Ref 207483 Rev 102 NOTES ...