IOM_FCW-FCCW_10a120_207995_181001_EN

Connect the water inlet and outlet pipes, observing the indications given on the side of the appliance.

Correctly insulate the water supply pipes to prevent dripping during the cooling mode of operation. A

shutoff valve should be inserted on the water supply pipe and balancing valve on the outlet pipe. The valve

body and balancing valve should also be p

roperly insulated to prevent dripping. It is the installer’s

responsibility to insulate properly and the manufacturer cannot be held liable for any insulation work.

NOTE:

It is always advisable to install the solenoid valve. In the heating mode of operation the solenoid

valve reduces consumption because upon reaching the set temperature the circulation of water is

stopped to avoid wasting energy (the fan coil would otherwise continue to heat like a radiator, even

with the motor at a standstill). In the cooling mode of operation the solenoid valve stops the

circulation of water when the set temperature is reached, this stopping the internal exchanger from

continuing to condense water with possible undesirable dripping into the floor. It also reduces

chiller operation with consequent energy savings.

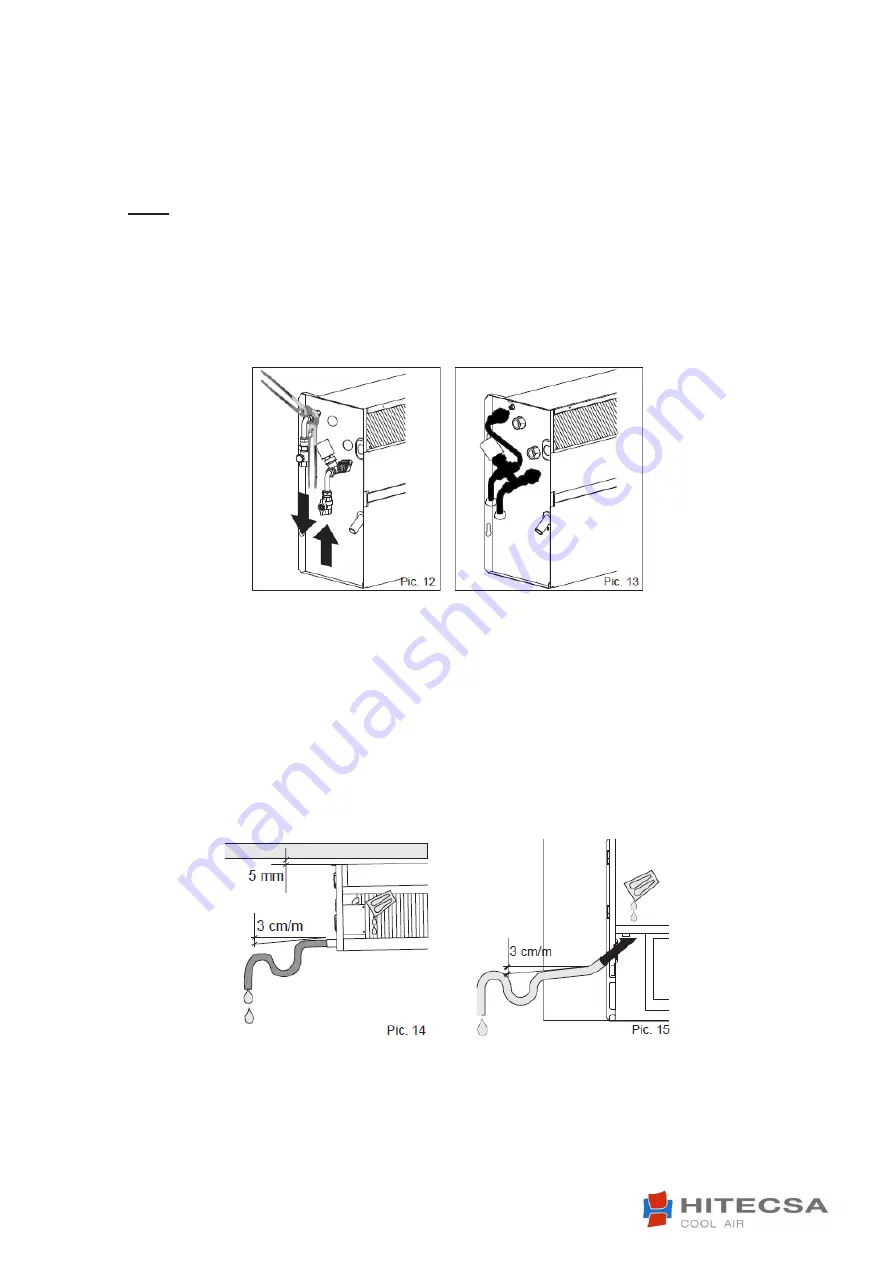

CONDENSATE WATER DRAINGE

The condensate drain pipe should slope downwards by at least 3 cm/m and should not have ascending or

throttled section in order to ensure a regular flow of water. It is advisable for a trap to be fitted. The

condensate drain pipe should be connected to a rainwater drainage system. Do not use sewage system to

avoid possible smells in the event of evaporation of the water in the trap. Upon completion of work, check

that the condensate flows out properly by pouring water into the tray (see Pic. 14 and 15). The condensate

water drainage system should be fabricated in a workmanlike manner and should be periodically checked.

The manufacturer cannot be held liable for any damage caused by dripping in the absence of a solenoid

valve or of periodic maintenance of the drainage system.