HM-90&95-Ex Series

HITROL CO., LTD.

15

Failure Check

Cautions for

Removal

Transportation

and Cautions

for Assembly

Cautions for

Installation

Cautions for

Grounding

If there is a problem with operation, check the followings first.

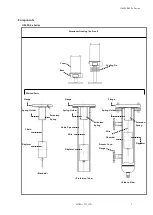

■ Remove the cover and check the output contact of snap switch. (Check the output by connecting

COM with N.O or N.C using a tester.) Replace the snap switch if necessary.

■ After checking the snap switch, remove the product and move up or down the displacer and recheck

the contact with the tester. When moving up of down the displacer, check the internal core (magnet)

and the fixed magnet on the switch block.

■ Recheck if the measuring point of fabricated product and level of measure object are leveled.

■ When moving up or down the displacer, check if the extension spring is correct displaced.

(HM-90-Ex Series)

■ Recheck if the float is positioned on top of the object to be measured.

(HM-95-Ex Series)

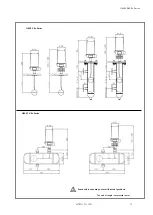

■ Pay special attention to prevent any impact on the product during transport or assembly.

The impact may directly lead to a failure.

■ When attaching the product to a vessel, pay attention to prevent any damage to the assembly

packings.

■ Check the level and presence of object to be measured in the vessel before removing it.

■ The product may be overheated so wear gloves to prevent burns.

■ If there is explosive gas in the atmosphere, do not open the cover.

■ Make sure that any O-ring or gasket is not damaged while opening or closing the cover.

■ To remove the cover of an ex-proof product, release the lock key first.

■ Use the same standard flange or screws.

■ Make sure to insert washers between bolts and nuts to prevent loosening.

■ Make sure to insert gaskets between flanges.

(Select the gaskets in consideration of the temperature of the content and the pressure of the

container.)

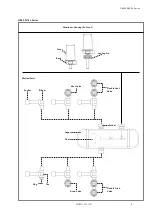

■ Install an ex-proof product in an ex-proof zone.

Make sure that the product would not be subject to any high impact during transport or

assembly.

External ground is located on top of the cable entry, and the grounding wire to connect

external ground must be 4 mm

2

(4 mm SQ). (Internal ground is connected before shipment.)

Make sure to insert a washer if the terminal lug is removed from the ground

terminal and then reconnected (to prevent loosening).