138

8.1.3 Controlled Axis and the Names of Axes

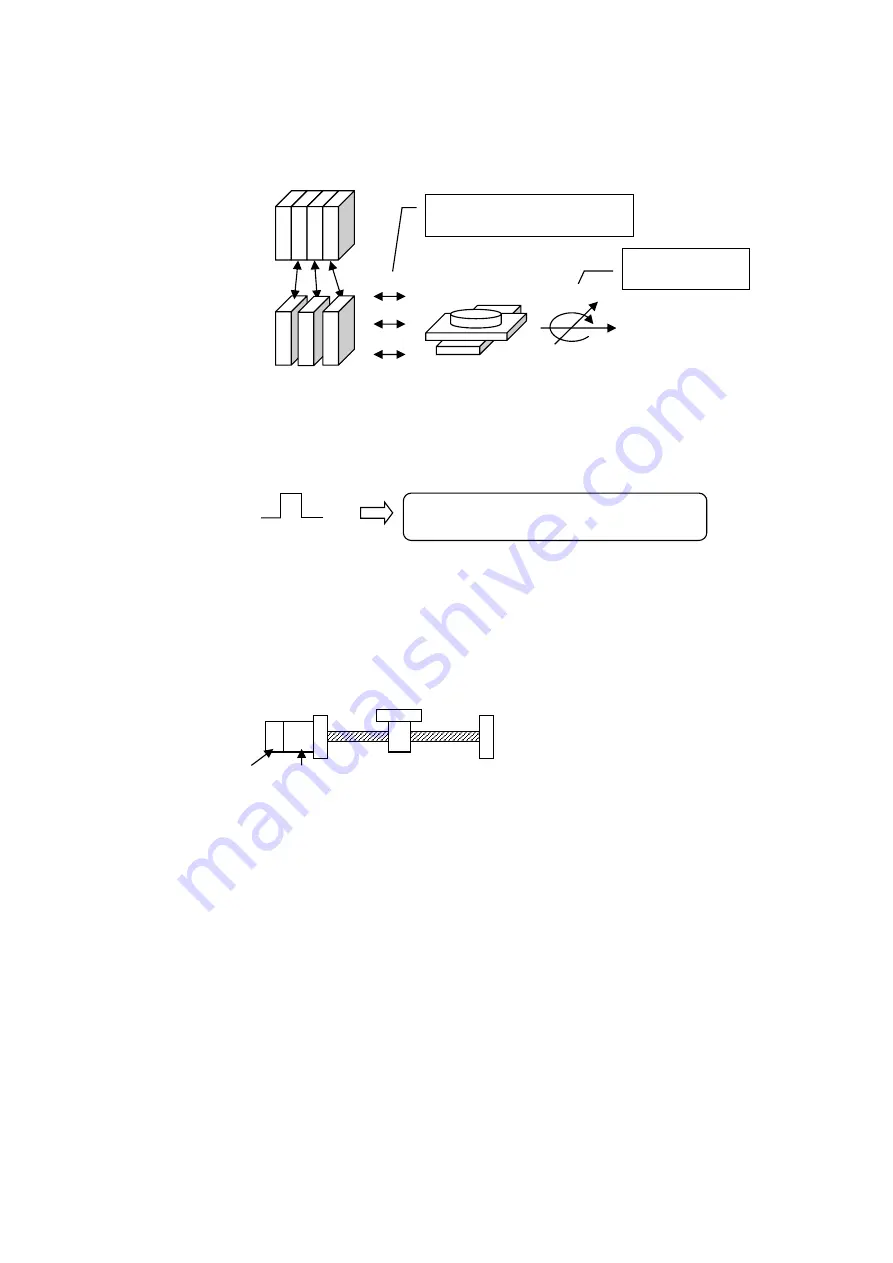

A control axis originally refers to a coordinate which is controlled by the device.

The motion controller control axis and the device axis must correspond.

8.1.4 Control Command Units

Both servo motor and stepping motor are controlled by pulse-train signals. The smallest unit for the control is 1

pulse.

1 command pulse

The relationship between the pulse and the motor rotation angle (position)/rotation speed is as follows:

⚫

The rotation angle (position) is proportional to the number of pulses (pulses).

⚫

The rotation speed is proportional to the pulse frequency (pps).

The amount of machine operation per one pulse is determined by the machine design.

<With ball screw driving>

Screw lead = 10(mm), with 1000(p/r) encoder

Screw lead 10 (mm) means the distance moved by a single motor rotation is 10 (mm).

A single motor rotation is 1000 pulses, which means the travel distance for one pulse is

10/1000(mm) = 0.01(mm).

Thus, 1 / 0.01 = 100 pulse commands are necessary to move 1mm.

In the same way, the machine speed of 1 pulse/second will be as follows:

The travel distance for one pulse is 0.01 (mm), which means 1(pps) = 0.01 (mm/s).

For example, to move at 10mm/s, the speed of 10 / 0.01 = 1000 (pps) must be issued as a command.

ID 0 1 2 3

ID:0

ID:0

ID:1

ID:1

Y-axis

Motion controller

Control axis (of the software)

Motion

controller

Names of axes on

the device

X-axis

ID:2

ID:2

θ-axis

Motor driver

XYθ stage

With stepping motor: 1 step angle rotation

With servo motor: Encoder rotation for 1 pulse

Encoder

Carriage

Motor

Summary of Contents for motionCAT HCPCI-MNT720M

Page 3: ......

Page 12: ...1 Warnings and Precautions...

Page 20: ...9 1 motionCAT Installation...

Page 109: ...98 4 Installation Guide...

Page 118: ...107 5 Device Driver Installation...

Page 122: ...111 6 Trial Operation...

Page 145: ...134 7 Accessories...

Page 147: ...136 8 Glossary...

Page 161: ...150 9 Connections to Drivers Supplied by Manufacturers...