20 / 183

Assembly and Commissioning Instructions Servo amplifier D1-N

15.10.2015

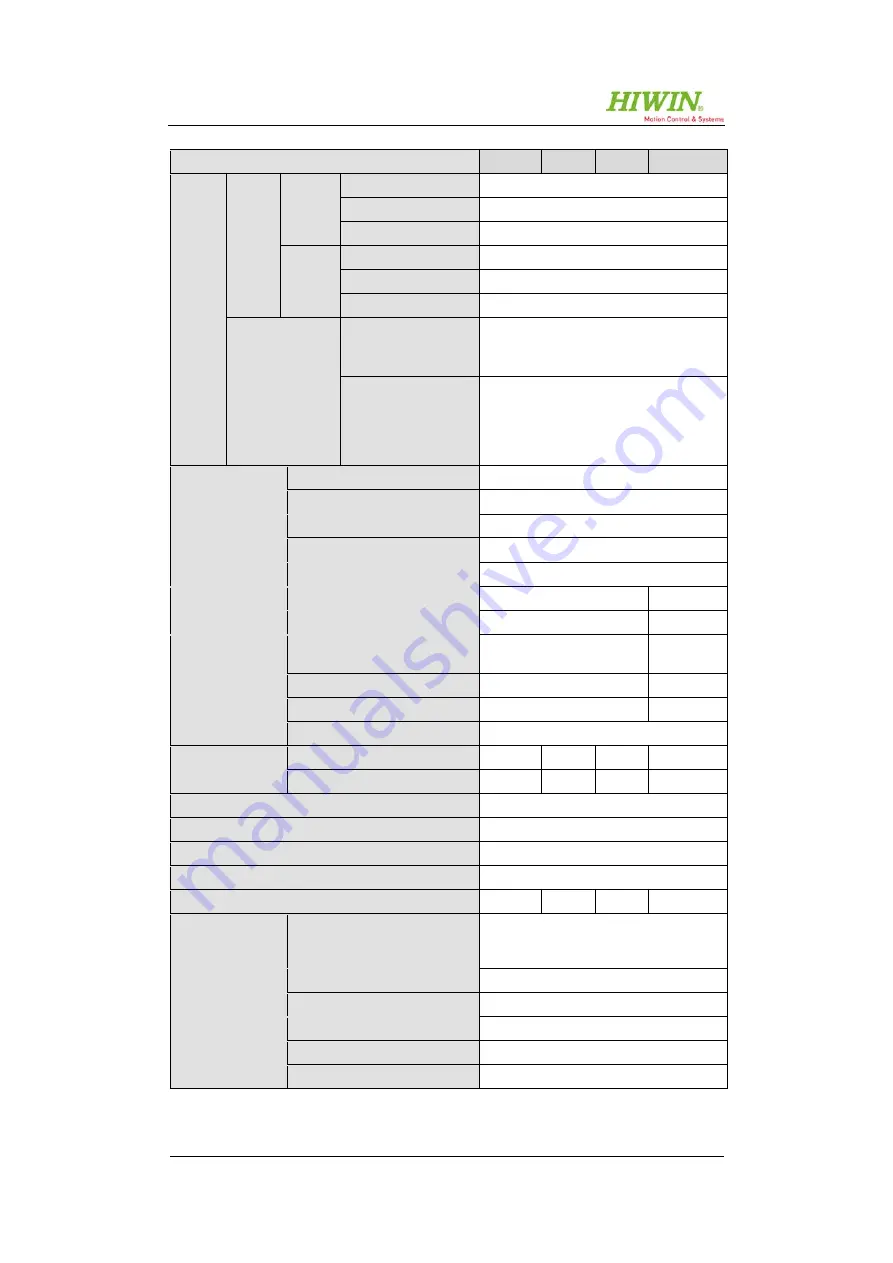

HIWIN D1-N servo drive amplifier

09

18

36

90

N

omi

na

l v

al

ue

inp

ut

s

Tor

qu

e r

eg

ul

at

ion

Analogue

Input resistance

10

k

Ω

Input voltage

±10

VDC

Resolution

12 bit

Digital

Function

Step/direction, CW/CCW

PWM frequency

Min. 36.5

kHz, max. 100

kHz

Min. pulse duration

220

ns

EtherCAT

Functions

PDO communication (flexible mapping)

SDO communication

Distributed clocks

CiA402 Modes

Profile Position Mode (1)

Profile Velocity Mode (2)

Cyclic Synchronous Position Mode (8)

Cyclic Synchronous Velocity Mode (9)

Homing (6)

Inputs / outputs

which can be pa-

rameterised

10 digital inputs

Function can be freely selected

3 digital outputs

Function can be freely selected

Brake control

24

VDC, max. 1

A

Capture input

Reaction time <7

ns (Input PCP)

CAM output

Reaction time <7

ns (Output PT), 5

VDC

DC-Bus

Overvoltage

+HV >404

VDC

+HV >800

VDC

Undervoltage

+HV <60

VDC

+HV <158

VDC

Brake

resistor

Connection

Internal (50

Ω

/150

W)

and/or external

External only

Activation threshold

+HV >390

VDC

+HV >735

VDC

Deactivation threshold

+HV <380

VDC

+HV <695

VDC

Tolerance

±5

%

Cooling

External heatsink

No

No

Yes

Yes

Integrated fan

No

Yes

Yes

Yes

EMC filter

No EMC filter integrated

Safety function

STO (Safe Torque Off)

User interface

LCD

Parameterisation interface

USB 2.0

Weight

2,05

kg

2,2

kg

3

kg

5,8

kg

Ambient conditions

Ambient temperature

Operation: 0 to 50

°C (above 50

°C with air

conditioning)

Transport / storage: –25 to 65

°C

Air humidity

0 to 90

%, non-condensing

Operating altitude

Up to 1000

m above sea level

Vibrations

1

G (10 to 500

Hz)

Protection class

IP20

Pollution

Degree 2

Table 3.3: Technical specification