9.3. Repairs of the break downs.

Review the circumstances and identify causes before start of a break down repairs. Remember that

great majority of break down reports results from incorrect setup, malfunctioning sensors, poor

water circuit system, inadequate quality of the fuel. When the breakdown indeed affects a part of a

subsystem, dismantle it and replace with a good one. All warranty services and spare parts must be

documented with the service coupons. They provide the basis for claims recognition.

9.4. Annual inspection.

The inspection shall be carried out at the expense of the service requested by the user. Annual

inspection is mandatory for warranty performace, The inspection must not be more frequent than

every 8 months and less frequent than every14 months. After the inspection the service shall be

satisfied that the boiler has been installed correctly and is operated as assumed in the Operation

manual. The following items shall be checked in particular:

•

gaskets on the doors and on the container's top cover;

•

the burner;

•

the ceramic deflector;

•

insulation;

•

the auger;

•

extra devices (ex. vertex guides, cleaning system of the heat exchange, etc.)

•

operation of the controller, fan and the fuel feed;

•

prevention against low temperature corrosion;

whether any repairs by unauthorised personnel had been effected.

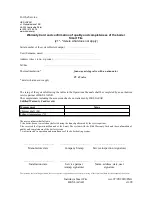

Worn out pieces and minor defects shall be replaced and repaired. The service shall make a proper

entry in the warranty card noting its remarks and recording the repairs done. The inspection shall be

recorded on the service coupon and mailed to the HKS LAZAR for registration purposes.

Instrukcja Smart Fire

wer. 07/05/2010/ENG

HKS LAZAR

str.20