24

Grease:

Inspect pins and bushing components before each use.

Unusual play or noise could be an indication of worn

parts. Parts replacement should be performed by

qualified

personnel.

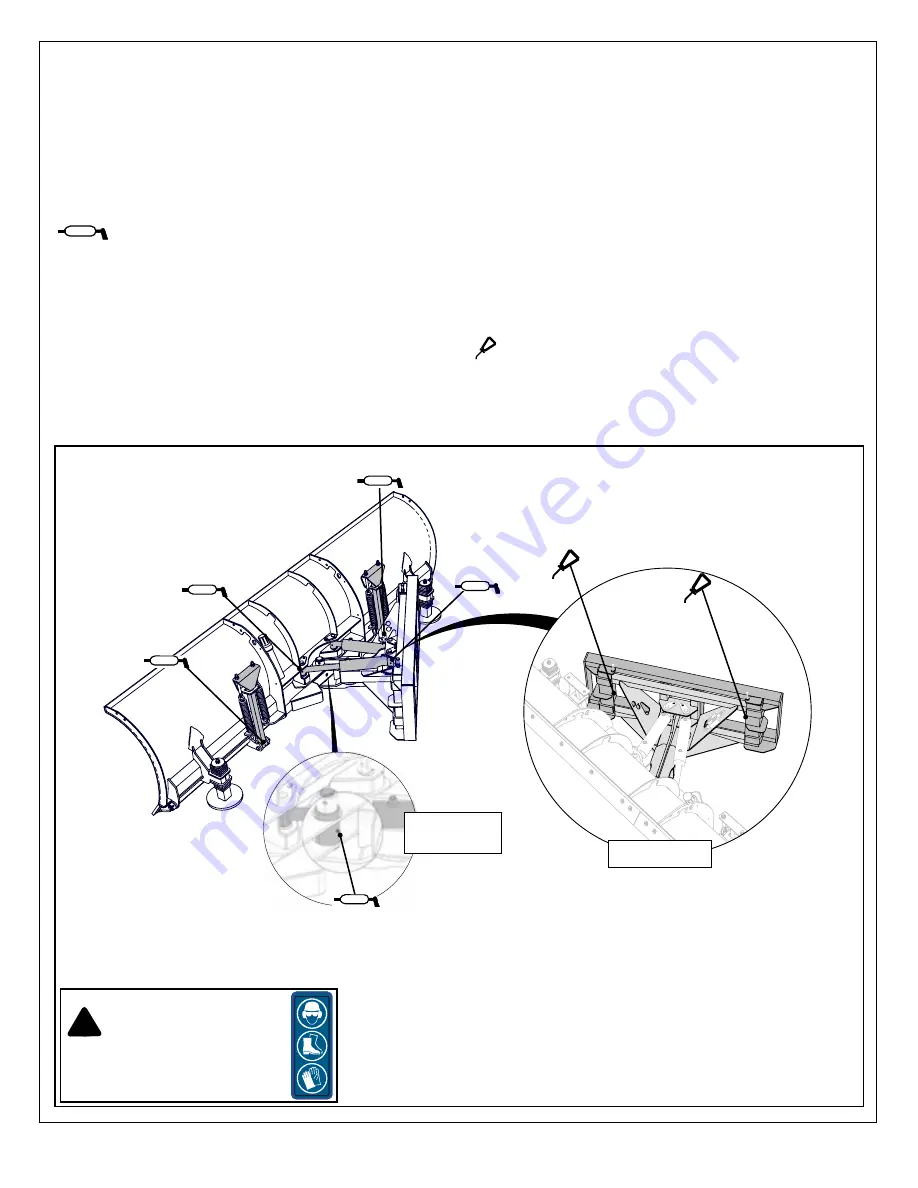

To prevent premature wear the grease zerks on the SB

series pins and bushings should be greased yearly or

more often with heavy use.

This symbol indicates a grease zerk location

shown in the illustrations below.

• Lubricate with an good Lithium EP2 grease or

equivalent.

• Use a hand-held grease gun for all greasing, one shot

of grease is adequate.

• Wipe grease zerk with a clean cloth before greasing,

to avoid injecting dirt and grit.

!

CAUTION

Operational Hazard

Personal Protection Equipment

(PPE) is required when operating

or maintaining this machine.

SNL00001

•

Replace any broken zerk fittings immediately.

• If grease zerk will not take grease, remove and clean

thoroughly. Also clean lubricant passageway. Replace

fittings if necessary.

Lubricate:

Inspect snow blade components before each use.

Unusual play or noise could be an indication of worn

parts. Parts replacement should be performed by

qualified personnel.

To ensure freedom of movement and prevent corrosion

the SB series snow blade slide and pivot points should be

lubricated yearly or more often with heavy use.

This symbol indicates a lubrication point shown in the

following illustrations.

Use a light oil or lubricating spray.

SB3000 Series

Horizontal

pivot pin

Lateral Float