OM–198 683 Page 36

Table 6-1. Drive Roll And Wire Guide Kits

Note

Base selection of drive rolls upon the following recommended usages:

1

V-Grooved rolls for hard wire.

2

U-Grooved rolls for soft and soft shelled cored wires.

3

U-Cogged rolls for extremely soft shelled wires (usually hard surfacing types).

4

V-Knurled rolls for hard shelled cored wires.

5

Drive roll types may be mixed to suit particular requirements (example: V-Knurled roll in combination

with U-Grooved).

Ref. S-0026-B/7-91

Wire Diameter

Fraction

Decimal

Metric

.023/.025 in.

.030 in.

.035 in.

.045 in.

.023/.025 in.

.030 in.

.035 in.

.045 in.

0.6 mm

0.8 mm

0.9 mm

1.2 mm

Kit No.

087 131

079 594

079 595

079 596

Drive Roll

Part No.

Type

087 130

053 695

053 700

053 697

V-Grooved

V-Grooved

V-Grooved

V-Grooved

Inlet

056 192

056 192

056 192

056 193

Wire Guide

1/16 in.

.062

1.6 mm

079 598

053 699

V-Grooved

056 195

.052 in.

.052

1.3 mm

079 597

053 698

V-Grooved

056 193

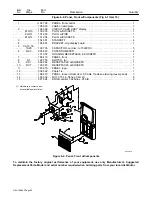

Description

Part

No.

Dia.

Mkgs.

Item

No.

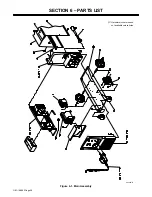

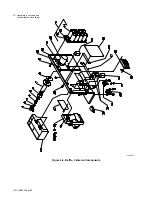

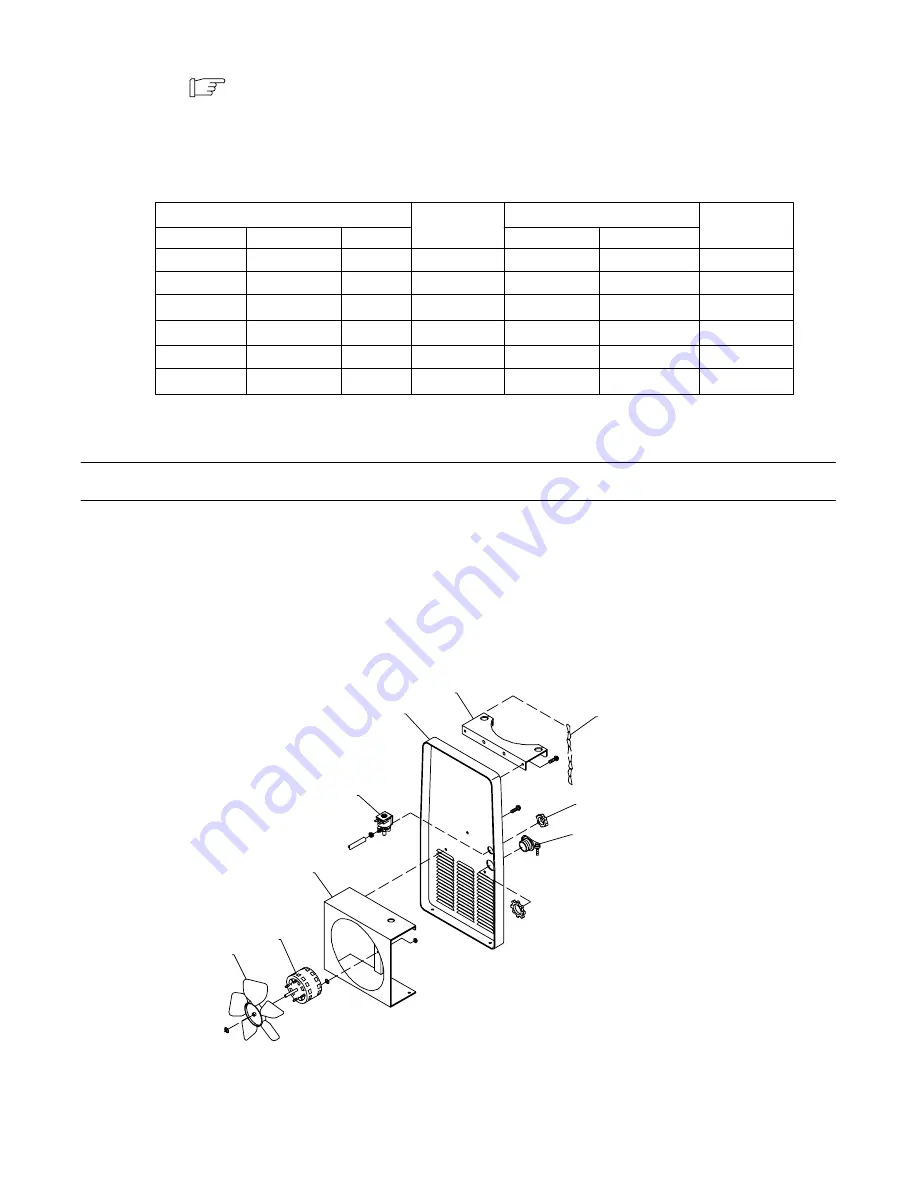

Figure 6-6. Panel, Rear w/Components (Fig 6-1 Item 3)

Quantity

1

148 809

BLADE, fan 9 in 5wg 34deg .309 bore CCW

1

. . .

. . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

2

FM1

188 706

MOTOR, fan 230V 50/60 Hz 1550RPM .312dia shaft

1

. . .

. . .

. . .

. . .

. . . . . . . . . . . . . . . . . . .

3

188 709

WINDTUNNEL, 9 in

1

. . .

. . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

GS1

125 785

VALVE, 24VAC 2 way custom port 1/8 orf

1

. . .

. . .

. . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

143 810

+PANEL, rear

1

. . .

. . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

169 654

BRACKET, support tank

1

. . .

. . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

188 441

CHAIN, weldless 2/0 x 31.000 lg

1

. . .

. . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

605 227

NUT, nyl hex jam .750NPST

1

. . .

. . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

178 126

CONNECTOR, clamp cable .690/1.070

1

. . .

. . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

193 328

LABEL, warning

1

. . . . . . . . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ref. 802 088-A

.

Hardware is common and

not available unless listed.

1

2

3

4

5

6

7

8

9

Figure 6-6. Panel, Rear w/Components

+When ordering a component originally displaying a precautionary label, the label should also be ordered.

To maintain the factory original performance of your equipment, use only Manufacturer’s Suggested

Replacement Parts. Model and serial number required when ordering parts from your local distributor.

Summary of Contents for IronMan 275

Page 4: ......

Page 20: ...OM 198 683 Page 16 2 15 Weld Parameter ...

Page 21: ...OM 198 683 Page 17 196 843 VOL TAGE V V WIRE SPEED ...

Page 30: ...OM 198 683 Page 26 Notes ...

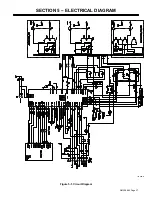

Page 31: ...OM 198 683 Page 27 SECTION 5 ELECTRICAL DIAGRAM 197 699 D Figure 5 1 Circuit Diagram ...

Page 41: ...Notes ...

Page 42: ...Notes ...