OM-498 Page 16

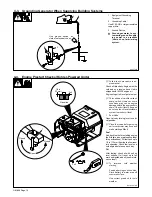

4-7.

Connecting To Weld Output Terminals

196 921 / 495 179

1

Positive (+) Weld Output

Terminal

2

Negative (–) Weld Output

Terminal

For Direct Current Electrode Posi-

tive (DCEP), connect work cable to

Negative (–) terminal and electrode

holder to Positive (+) terminal.

For Direct Current Electrode nega-

tive (DCEN), reverse cable con-

nections.

Tools Needed:

3/4 in

1

2

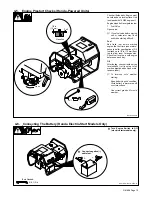

4-8.

Selecting Weld Cable Sizes*

Weld Cable Size** and Total Cable (Copper) Length in Weld Circuit

Not Exceeding***

100 ft (30 m) or Less

150 ft

(45 m)

200 ft

(60 m)

250 ft

(70 m)

300 ft

(90 m)

350 ft

(105 m)

400 ft

(120 m)

Weld Output

Terminals

Stop engine before

connecting to weld out-

put terminals.

Do not use worn, dam-

aged, undersized, or

poorly spliced cables.

Welding

Amperes

10 – 60%

Duty

Cycle

60 – 100%

Duty

Cycle

10 – 100% Duty Cycle

100

4 (20)

4 (20)

4 (20)

3 (30)

2 (35)

1 (50)

1/0 (60)

1/0 (60)

150

3 (30)

3 (30)

2 (35)

1 (50)

1/0 (60)

2/0 (70)

3/0 (95)

3/0 (95)

200

3 (30)

2 (35)

1 (50)

1/0 (60)

2/0 (70)

3/0 (95)

4/0 (120)

4/0 (120)

250

2 (35)

1 (50)

1/0 (60)

2/0 (70)

3/0 (95)

4/0 (120)

2 ea. 2/0

(2x70)

2 ea. 2/0

(2x70)

*

This chart is a general guideline and may not suit all applications. If cable overheating occurs (normally you can smell it), use next size larger

cable.

**Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere.

( ) = mm

2

for metric use

S-0007-E

***For distances longer than those shown in this guide, call a factory applications representative at 920-735-4505.

Summary of Contents for 1435

Page 4: ......

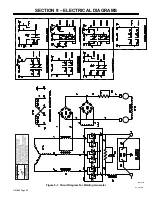

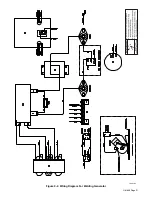

Page 35: ...OM 498 Page 31 198 014 C Figure 9 2 Wiring Diagram For Welding Generator ...

Page 36: ...OM 498 Page 32 201 026 A Figure 9 3 Wiring Diagram For Auxiliary Power Panels 1 Of 2 ...

Page 37: ...OM 498 Page 33 201 026 A Figure 9 4 Wiring Diagram For Auxiliary Power Panels 2 Of 2 ...

Page 53: ...OM 498 Page 49 Notes ...

Page 58: ...OM 498 Page 54 Notes ...